3D Laser Scanner Market Analysis and Insights:

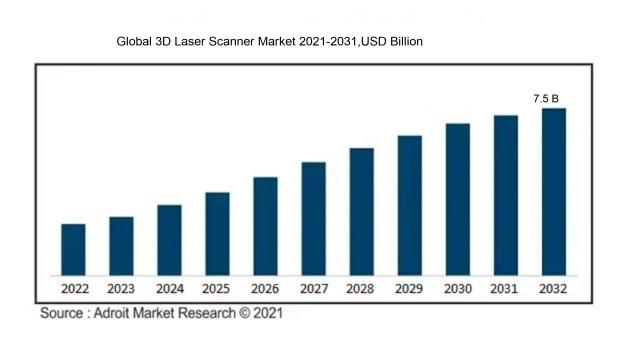

In 2023, the size of the worldwide 3D Laser Scanner market was US$ 3.7billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 8.60% from 2024 to 2032, reaching US$ 7.5 billion.

The market for 3D laser scanners is primarily fueled by numerous influential factors, notably the growing necessity for accuracy in sectors such as construction, manufacturing, and the preservation of cultural heritage. Advances in scanning technology, including enhancements in resolution and accelerated data collection, significantly boost the attractiveness of 3D laser scanners across various uses, including surveying and quality assurance. The increasing implementation of Building Information Modeling (BIM) and the demand for efficient asset management systems further stimulate market expansion, as these systems depend on precise 3D models. Moreover, the growth of industries such as automotive, aerospace, and healthcare, where swift prototyping and thorough inspections are crucial, adds to the market's momentum. Additionally, the convergence of 3D laser scanning with cutting-edge technologies like augmented reality (AR) and virtual reality (VR) is opening new avenues, improving the overall user experience and broadening application prospects across a range of fields.

3D Laser Scanner Market Definition

The market for 3D laser scanning comprises tools and technologies designed to obtain accurate three-dimensional measurements of both physical entities and surroundings. This sector caters to numerous industries, such as construction, manufacturing, and the preservation of cultural heritage, facilitating intricate modeling and in-depth analysis.

The market for 3D laser scanning technology is vital across numerous sectors by delivering precise and intricate three-dimensional models of tangible objects and settings. These devices significantly enhance accuracy in areas such as architecture, construction, manufacturing, and the preservation of cultural heritage, thereby improving planning, design, and evaluation processes. They also boost operational efficiency and lower expenses through swift data collection and analysis, while reducing the likelihood of human error. Moreover, progress in 3D scanning technologies fosters new opportunities in fields like virtual reality and robotics, promoting innovation and competitive edge. As businesses progressively embrace digital transformation strategies, the need for 3D laser scanning solutions is on the rise, highlighting the importance of this market.

3D Laser Scanner Market Segmental Analysis:

Insights On Key Range

Short Range

Short-range scanners category is expected to dominate the global 3D laser scanner market since they cater predominantly to close-proximity applications requiring high precision. Industries like quality control, reverse engineering, and intricate modeling significantly benefit from these devices. Their ability to capture detailed datasets even in confined spaces makes them invaluable tools for professionals needing precision over wider spatial coverage. Thus, while they serve a crucial role in specific applications, they do not have the broad market appeal that medium-range scanners possess.

Medium Range

The medium range category is growing due to its versatility and wide applicability across several industries. Medium-range scanners bridge the gap between short and long-range equipment, providing significant detail and accuracy for a variety of tasks. Applications in construction, architecture, and industrial design require the ability to capture detailed dimensions of medium-sized spaces, making medium-range scanners essential tools for professionals. Furthermore, the increasing demand for precise measurements in civil engineering and site surveys supports this growth. The adaptability of medium-range scanners for both large and intricate projects particularly cements their position as the leading choice.

Long Range

Long-range scanners are optimized for expansive environments and large structures, such as bridges and buildings. While they are effective for surveying massive areas and suitable for large-scale projects, they often lack the precision required for intricate, close-up work. This makes them less versatile compared to medium-range scanners, which can handle a wider breadth of applications. They do serve niches where long-distance data capture is necessary, but their limited scope in high-detail applications keeps them from leading the market.

Insights On Key Product

Portable CMM Based

The Portable CMM Based category, notably featuring articulated arm and handheld devices, is anticipated to dominate the Global 3D Laser Scanner Market. This growth is primarily driven by the increasing demand for flexibility and mobility in measurement applications across various industries, including automotive, aerospace, and construction. As businesses seek to enhance productivity and accuracy in field operations, portable three-dimensional scanners offer unique advantages, allowing for on-site evaluations and quick data acquisition. Furthermore, advancements in technology have made portable models more reliable and capable of providing high-resolution scans, thereby solidifying their preference among users and driving market expansion.

Tripod Mounted

The Tripod Mounted category is recognized for its stability and precision, making it suitable for various surveying and engineering tasks. This type of device is particularly favored in controlled environments where exact measurements are paramount. While it does not match the portability of handheld models, it compensates with superior accuracy over large distances. As industries that require high-level detail, such as architecture and heritage conservation, continue to develop, tripod mounted scanners hold a critical position due to their robustness and reliability, catering to extensive, intricate projects that necessitate meticulous data collection.

Fixed CMM Based (Bridge CMM, Gantry CMM, Horizontal Arm CMM Based)

The Fixed CMM Based category, which includes Bridge, Gantry, and Horizontal Arm CMMs, caters to settings that require stationary equipment capable of executing precise measurements. These devices excel in controlled environments, often seen in manufacturing and quality assurance processes where high precision is fundamental. Despite being less versatile than portable options, their ability to deliver consistent accuracy over time makes them indispensable in production lines and factory settings. As industries aim for ened quality control and productivity, the Fixed CMM Based equipment maintains its significance, offering solutions that assure seamless integration into manufacturing workflows.

Portable CMM Based (Articulated Arm CMM, Handheld, Desktop)

The Portable CMM Based category encompasses Articulated Arm CMMs, handheld units, and desktop scanners that provide unparalleled convenience and adaptability for users needing immediate measurement capabilities. These devices are particularly valuable in fields like automotive inspection and reverse engineering, where mobility is a key requirement. Additionally, the push towards automation and smart manufacturing enhances the attractiveness of portable models, as industries increasingly adopt flexible measurement solutions. As a result, the demand for these devices continues to surge, emphasizing their crucial role in modern metrological applications.

Insights On Key Application

Quality Control and Inspection

Quality control and inspection are poised to dominate the Global 3D Laser Scanner Market due to the increasing emphasis on precision and accuracy across manufacturing industries. As companies strive for high-quality products and compliance with stringent industry standards, 3D laser scanning technology provides a reliable solution for measuring, analyzing, and validating components and assemblies. The ability to quickly capture detailed data helps in identifying defects, ensuring that products meet quality benchmarks, and facilitating rapid iterations in design. This trend is further supported by advancements in scanning technology, which enable real-time analysis, thus driving demand in sectors such as aerospace, automotive, and electronics.

Reverse Engineering

Reverse engineering represents a significant application of 3D laser scanning, allowing businesses to analyze and replicate existing products. This method is especially valuable for companies aiming to enhance product designs or reproduce obsolete components. 3D laser scanners provide precise measurements of physical objects, transforming them into digital models that can be modified without the need for original design documents. This application is crucial for innovation, enabling manufacturers to improve performance and functionality in a competitive market landscape.

Virtual Simulation

Virtual simulation utilizes 3D laser scan data for modeling and analysis, facilitating better decision-making in design and development. This application has gained traction in diverse industries, including architecture, engineering, and video game development. By creating highly detailed visualizations, organizations can explore different scenarios in a risk-free environment, leading to enhanced creativity and efficiency. The growing adoption of virtual and augmented reality technologies further bolsters the demand for 3D laser scanners in simulation applications.

Others

The "Others" category encompasses various niche applications of 3D laser scanners, less prevalent but increasingly relevant. This includes applications in heritage preservation, environmental assessment, and cultural artifact documentation. While these areas may not dominate the market like quality control and inspection, they present unique opportunities for 3D laser scanning technology. Preservation of historical sites and artifacts often requires meticulous detail; thus, 3D scanning can capture intricate features that traditional methods might miss. As awareness of digital conservation grows, this is expected to experience slow but steady growth.

Insights On Key Offering

Hardware

The hardware is expected to dominate the Global 3D Laser Scanner Market due to the continuous advancements in technology alongside an increasing demand for high-precision scanning solutions across various industries. Innovations in scanner design and improvements in laser technologies have increased scanning efficiency and accuracy, leading to greater adoption. Key applications in construction, manufacturing, and archeology en the need for durable and efficient 3D scanning devices. Additionally, the integration of advanced features such as portability and user-friendly interfaces enhance the appeal of hardware offerings. This solidifies hardware as the crucial driver of the market, making it the leading category within the 3D laser scanner landscape.

Software

Software plays a vital role in the 3D Laser Scanner Market by providing critical tools necessary for data processing, visualization, and analysis. As hardware capabilities grow, the demand for sophisticated software solutions to interpret the data generated by laser scanners has also increased. This includes advanced algorithms for point cloud processing and integration with CAD programs, which are essential for industries such as architecture and engineering. While software will continue to see growth due to technological advancements, it remains complementary to hardware, thereby garnering a significant share but not surpassing hardware's dominance.

After Sales Services

After sales services will also hold an important position in the 3D Laser Scanner Market by ensuring customer satisfaction and promoting product longevity. Services such as maintenance, training, and technical support are crucial, especially as users become increasingly reliant on complex scanning equipment. Companies that provide exceptional after-sales services can build long-term relationships with clients, helping to drive repeat business and brand loyalty. However, this is less likely to surpass hardware in terms of overall market share, as it primarily supports the hardware and software offerings in enhancing user experience and operational efficiency.

Insights On Key End User

Architecture and Construction

Architecture and Construction is poised to dominate the Global 3D Laser Scanner Market due to its significant demand for precise measurements and enhanced design capabilities. The sector has increasingly adopted advanced technologies to improve design accuracy, streamline construction processes, and reduce wastage. Architects and construction managers utilize 3D laser scanners to capture the exact dimensions of existing structures and project sites, allowing for better planning and execution. Moreover, the growing focus on Building Information Modeling (BIM) and the trend of smart buildings accentuate the need for detailed 3D scanning in construction projects, reinforcing its position as the leading end user in this market.

Automotive

The Automotive sector is experiencing a notable increase in the adoption of 3D laser scanning technologies for quality control, design verification, and reverse engineering. Automotive manufacturers leverage laser scanning to inspect and compare parts and assemblies swiftly and accurately. This process enhances the manufacturing workflow by ensuring high standards of precision and efficiency. As the automotive industry evolves toward electric and autonomous vehicles, the demand for precise engineering solutions will further drive the uptake of 3D laser scanners.

Healthcare

In the Healthcare industry, the use of 3D laser scanning is becoming increasingly relevant, particularly in fields such as prosthetics, orthotics, and dental applications. Medical professionals employ these scanners for patient-specific design and fitting of medical devices. High accuracy and the ability to create digital models of body parts have revolutionized how healthcare providers develop tailored solutions. The continuous advancements in medical technology are expected to further boost the adoption of 3D scanning in healthcare, though it currently trails behind other sectors.

Aerospace and Defence

The Aerospace and Defence sector has a growing demand for 3D laser scanning, primarily for inspection and maintenance of aircraft and military equipment. The need for compliance and safety in this highly regulated industry requires precise measurements and quick inspections of complex components. While the market is potential-rich due to technological innovations and increasing defense budgets, it is slightly overshadowed by the more extensive demands from architecture and construction.

Energy and Power

In the Energy and Power sector, 3D laser scanning holds significant value in project development, particularly for the planning and management of facilities such as power plants and wind farms. The technology enables accurate site assessments and can facilitate upgrades in infrastructure and safety inspections. However, given the slower adoption rates compared to construction-related projects, its prominence within the overall market remains limited, even as industry players seek to improve operational efficiency and reduce costs.

Tunnel and Mining

Within the Tunnel and Mining industry, 3D laser scanning is utilized for surveying and mapping, enhancing safety and planning efforts. This technology allows for detailed modeling of underground environments and can significantly reduce time and costs associated with exploration and excavation. However, despite its essential applications, the sector does not dominate the market compared to areas such as architecture and construction, where the need for comprehensive, real-time data acquisition is more pronounced.

Global 3D Laser Scanner Market Regional Insights:

North America

North America is expected to dominate the Global 3D Laser Scanner Market due to its advanced technological landscape and a strong emphasis on research and development. The presence of leading market players and manufacturers in the region promotes innovation and enhances product offerings. The U.S. particularly leads in the adoption of 3D laser scanning technologies across sectors such as construction, manufacturing, and architecture. Additionally, increasing investments in infrastructure projects and a growing focus on automation and efficiency are driving the demand for advanced scanning solutions. The regulatory environment also supports the use of high-precision technologies, further solidifying North America's leading position.

Latin America

Latin America is gradually adopting 3D laser scanning technologies, particularly in the construction and architecture sectors. However, challenges such as limited budgets and slower technological adoption rates compared to developed regions hinder rapid growth. Despite this, countries like Brazil and Mexico are witnessing emerging opportunities as construction projects increase and industries modernize. The potential for growth in this market remains, as businesses recognize the benefits of accurate measurements and data collection.

Asia Pacific

Asia Pacific is experiencing a significant rise in the 3D laser scanner market, fueled by rapid industrialization and urbanization. Countries such as China, India, and Japan are investing heavily in infrastructure projects, leading to increased demand for 3D scanning solutions. The region's growing tech-savvy population and improving economic conditions are also allowing markets to mature. However, the competitive environment with numerous local players might affect pricing strategies and market share.

Europe

Europe's 3D laser scanner market is robust, driven by their adoption in industries like automotive, manufacturing, and construction. Countries such as Germany and the UK are leading in technological advancements and implementation. The region may face challenges regarding regulatory compliance and high initial costs compared to other regions. Nonetheless, the emphasis on precision engineering and quality assurance challenges supports a steady demand for advanced scanning technologies, particularly within the highly regulated sectors.

Middle East & Africa

The Middle East & Africa region exhibits moderate growth in the 3D laser scanner market due to ongoing development projects and increasing investments in construction. Nevertheless, it faces challenges like political instability, economic fluctuations, and less widespread technological adoption. While there are some opportunities arising from infrastructural investments in nations such as the UAE and South Africa, overall market growth remains slower compared to more developed regions. Enhanced integration of technology in various sectors may boost demand in the future.

3D Laser Scanner Market Competitive Landscape:

Major contributors in the Global 3D Laser Scanner Market are fostering innovation by creating cutting-edge scanning technologies and broadening product applications in diverse fields such as architecture, construction, and manufacturing. Additionally, they emphasize forming strategic alliances and mergers to strengthen their market position and enhance solutions for customers.

Prominent entities in the 3D laser scanning sector comprise Faro Technologies, Inc., Trimble Inc., Leica Geosystems AG, RIEGL Laser Measurement Systems GmbH, Nikon Metrology, Inc., Zoller & Fröhlich GmbH (Z+F), Topcon Positioning Systems, Inc., Carlson Software, Inc., 3D Systems Corporation, and Perceptron, Inc. Other significant players include Matterport, Inc., Aconex Limited, Hexagon AB, Solidworks Corporation, and SenseFly SA. Furthermore, the market encompasses companies like Sirnaut, Inc., GeoSLAM Ltd., Creaform, Inc., and deriscope GmbH.

Global 3D Laser Scanner Market COVID-19 Impact and Market Status:

The Covid-19 pandemic had a substantial impact on the Global 3D Laser Scanner Market, causing delays in projects, a decline in construction activities, and a temporary suspension of manufacturing processes. This resulted in a decreased demand for laser scanners and disrupted supply chains.

The COVID-19 pandemic had a profound effect on the 3D laser scanner sector, reshaping the landscape of both supply and demand. In the early stages, widespread lockdowns and disruptions in manufacturing processes created obstacles in production and logistics, resulting in significant project delays across various fields like construction, manufacturing, and engineering. Nevertheless, as businesses transitioned to remote work and implemented stricter safety measures, there was a notable increase in the demand for sophisticated measurement and scanning technologies. This shift was fueled by industries embracing digital transformation and automating their operations. Furthermore, the surge in infrastructure initiatives driven by government stimulus packages underscored the necessity for accurate data gathering and analysis. The pandemic also acted as a catalyst for the quicker adoption of technologies like Building Information Modeling (BIM) and Geographic Information Systems (GIS), which incorporated 3D scanning to enhance project efficiency. In summary, while the initial phases of the pandemic presented significant hurdles, the subsequent adjustments and advancements in technology stimulated a strong recovery and upward trajectory for the 3D laser scanner market.

Latest Trends and Innovation in The Global 3D Laser Scanner Market:

- In July 2023, Hexagon AB announced the acquisition of Aicon 3D Systems GmbH, a provider of 3D scanning and measurement solutions, aimed at enhancing their offerings in the field of automotive and aerospace industries.

- In June 2023, Trimble Inc. launched the X7 3D laser scanner, featuring improved imaging capabilities and a user-friendly interface. This innovative device emphasizes speed and accuracy, catering to construction and surveying applications.

- In January 2023, Faro Technologies, Inc. released the Focus Premium 3D laser scanner, which integrates advanced imaging technology and enhanced scanning speeds, allowing for detailed documentation of construction sites and historical buildings.

- In October 2022, Leica Geosystems, part of Hexagon, introduced the BLK2FLY, the world’s first smart flying laser scanner, which combines autonomous flight capabilities with advanced 3D laser scanning technology for capturing data in complex environments.

- In September 2022, RIEGL Laser Measurement Systems expanded its portfolio with the release of the VZ-400i 3D laser scanner, designed for high-speed data acquisition and reliability in various tough environmental conditions, strengthening their position in the industrial measurement.

- In April 2022, Autodesk, Inc., in collaboration with FARO, launched a new software solution that integrates FARO's 3D scanning with Autodesk Revit, enabling architects and engineers to create accurate digital models from scanned data more efficiently and effectively.

- In March 2022, Topcon Positioning Systems, Inc. announced the acquisition of the software company, 3D Laser Mapping, to enhance its capabilities in laser scanning and expand its product offerings in geospatial applications.

- In December 2021, Nikon Corporation unveiled the NEXIV VMZ-S series, a new line of 3D laser scanners that improves precision in measuring complex geometries, targeting the manufacturing sector for quality control and assurance applications.

- In November 2021, Zeiss Group introduced its T-SCAN 5 3D laser scanner. This product enhances efficiency in measurement tasks and is specifically designed for industrial quality assurance, underscoring Zeiss’s commitment to innovation in measurement technology.

- In October 2021, 3D Systems Corporation announced a partnership with Siemens to integrate 3D scanning and additive manufacturing technologies, aiming to streamline workflows and optimize processes in product design and engineering.

3D Laser Scanner Market Growth Factors:

The 3D laser scanner market is poised for growth driven by technological innovations, a growing need for accuracy in sectors like construction and manufacturing, and a ened embrace of automation across multiple industries.

The market for 3D laser scanning is witnessing remarkable expansion, driven by a multitude of factors. Primarily, the ened need for precision and reliability in sectors such as construction, manufacturing, and the preservation of cultural heritage fuels the demand for sophisticated scanning technologies. Furthermore, the growing trend of automation, along with the convergence of 3D laser scanning with cutting-edge technologies like robotics and artificial intelligence, significantly boosts efficiency and enhances data visualization.

The increasing prevalence of Building Information Modeling (BIM) in construction workflows mandates the application of 3D scanning for precise as-built documentation, further accelerating market development. Additionally, the automotive industry's growth, utilizing 3D laser scanning for quality assurance and design refinement, significantly influences market dynamics.

Cost reductions in scanning equipment and software, coupled with advancements in smaller, portable scanning devices, are making these technologies more accessible to small and medium enterprises. Moreover, government investments in infrastructure improvements and archaeological research underscore the relevance of 3D laser scanning, creating further opportunities within the market. Lastly, continuous improvements in scanning technology—characterized by faster data capture and superior imaging quality—are propelling innovation and facilitating greater adoption, thereby reinforcing the positive growth trajectory of the market.

3D Laser Scanner Market Restaining Factors:

The 3D laser scanner market faces several significant challenges, including elevated equipment prices, a lack of technical expertise among users, and regulatory hurdles present in certain sectors.

The market for 3D laser scanning is confronted with numerous challenges that may impede its expansion. The substantial investment required for cutting-edge scanning technology can be a significant barrier for smaller enterprises and startups, thus limiting their ability to penetrate the market. Additionally, the intricate nature of these devices necessitates a workforce skilled in both operation and data interpretation, which can be a notable obstacle in areas lacking qualified experts. The technology's vulnerability to varying environmental factors can result in variable outcomes, dissuading potential adopters from utilizing it for important tasks. Furthermore, the need to adhere to industry-specific regulations can complicate the integration of 3D laser scanning into established processes, causing organizations to hesitate. There is also competition from other measurement technologies that may constrain the growth of the 3D laser scanning sector. Despite these hurdles, advancements in technology paired with a growing awareness of its diverse applications can lead to an enhanced market landscape. As costs gradually decrease and innovation focuses on simpler, user-friendly solutions, there is substantial potential for broader adoption, ultimately cultivating a vibrant future for 3D laser scanning technology.

Key Segments of the 3D Laser Scanner Market

By Range

- Short

- Medium

- Long

By Product

- Tripod Mounted

- Fixed CMM Based

- Bridge CMM

- Gantry CMM

- Horizontal Arm CMM Based

- Portable CMM Based

- Articulated Arm CMM

- Handheld

- Desktop

By Application

- Quality Control and Inspection

- Reverse Engineering

- Virtual Simulation

- Others

By Offering

- Hardware

- Software

- After Sales Services

By End User

- Automotive

- Healthcare

- Aerospace and Defence

- Architecture and Construction

- Energy and Power

- Tunnel and Mining

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America