3D Printing In Medical Applications Market Analysis and Insights:

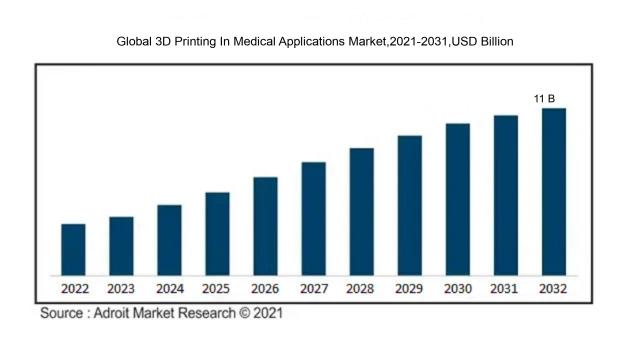

In 2023, the size of the worldwide 3D Printing In Medical Applications market was US$ 3.4 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 16.7 % from 2024 to 2032, reaching US$ 11 billion.

The market for 3D printing in medical applications is significantly influenced by technological advancements that improve the accuracy and effectiveness of medical devices and implants. The growing interest in personalized medicine is driving the creation of bespoke prosthetics and implants specifically designed for individual patients. Additionally, the increasing incidence of chronic illnesses calls for innovative therapeutic solutions, which in turn supports market expansion. Regulatory encouragement and financial backing for research in bioprinting and regenerative medicine play a crucial role in accelerating the integration of these technologies into medical use. Furthermore, the economical nature of 3D printing compared to conventional manufacturing methods appeals to healthcare providers aiming to lower costs while enhancing patient care quality. Lastly, the continued incorporation of 3D printing in surgical education and planning is improving procedural efficiency and results, thereby reinforcing its significance in the advancing field of medical technology.

3D Printing In Medical Applications Market Definition

The application of 3D printing in the medical field involves the fabrication of three-dimensional objects, including implants, prosthetics, and anatomical replicas, through specialized additive manufacturing methods designed for individualized healthcare. This innovative technology enhances the accuracy of surgeries and positively impacts patient results by facilitating personalized treatment strategies.

The utilization of 3D printing within the medical field is transformative, fundamentally changing how healthcare professionals conduct diagnosis, treatment, and patient management. This innovative technology enables the production of personalized implants, prosthetics, and anatomical models that are specifically designed for each patient, significantly improving surgical accuracy and patient outcomes. Furthermore, it streamlines the rapid prototyping of medical devices, leading to accelerated innovation and cost-effectiveness. In addition, 3D bioprinting offers promising possibilities for tissue engineering and regenerative medicine, setting the stage for the creation of functional organs. Ultimately, incorporating 3D printing into healthcare fosters a more individualized approach to patient care, enhances the accessibility of medical solutions, and drives forward progress in medical research and education.

3D Printing In Medical Applications Market Segmental Analysis:

Insights On Type of Component

Polymers

Polymers are projected to dominate the Global 3D Printing in Medical Applications market due to their remarkable versatility, ease of handling, and cost efficiency. They are widely utilized in fabricating medical devices, implants, and anatomical models. Polymers also exhibit desirable properties such as biocompatibility, making them suitable for a range of medical applications, including drug delivery systems and scaffolds for tissue engineering. With advancements in 3D printing technology improving the precision and quality of polymer products, their adoption in healthcare is anticipated to grow significantly, thereby consolidating their leading position in the market.

Metals & Alloys

Metals and alloys play a critical role in the 3D printing landscape for medical applications, particularly for creating strong and durable implants such as orthopedic and dental components. They offer superior mechanical properties and are essential for load-bearing applications where strength is crucial. Although the initial costs and complexity of metal printing processes may pose challenges, the demand for advanced surgical tools and prosthetics continues to drive adoption within the healthcare sector. Regulatory approvals for metal-based products in medical applications are also enhancing their attractiveness to manufacturers and hospitals alike.

Ceramics

Ceramics are emerging as significant materials in the 3D printing of medical applications, especially in bone substitutes and dental implants due to their excellent biocompatibility and aesthetic properties. They offer the rigidity and hardness required for dental and orthopedic applications, while their porous nature can facilitate bone ingrowth. Although ceramics face challenges in processing and brittleness during printing, innovations in ceramic printing technologies are expected to widen their application scope. Their growing popularity for personalized prosthetics and implant solutions underlines their potential in the medical 3D printing sector.

Photopolymers

Photopolymers are gaining traction in the medical 3D printing market due to their suitability for creating highly detailed, intricately designed models and prototypes. They are primarily used in applications such as soft tissue modeling and surgical guides where precision is crucial. The ability to quickly produce custom models for surgical planning enhances their value in clinical settings. However, they are limited by biocompatibility concerns and material performance under mechanical loads, restricting their use solely to non-load-bearing applications. Research continue to focus on improving their properties for expanded applications in the medical field.

Thermoplastics

Thermoplastics are utilized in various medical applications, primarily in the production of disposable devices, surgical tools, and customizable prosthetics. They offer a broad range of mechanical properties and can be easily processed, making them favorable for large-scale production. While thermoplastics do not provide the high mechanical strength found in metals, they excel in applications requiring flexibility and durability. Their ability to be reprocessed without losing integrity allows for sustainable practices in the production of medical devices. Advances in thermoplastic materials continue to expand their usability in the healthcare sector, particularly in areas where cost-effectiveness is essential.

Services

Services in the 3D printing encompass a range of activities, including software solutions, design assistance, printing services, and post-processing support for medical applications. These services enhance the efficiency of 3D printing processes and ensure that products meet regulatory standards. As healthcare providers seek to integrate 3D printing into their operations, the demand for specialized services continues to grow. However, while essential, this is typically considered supplementary to the primary components used in actual fabrication. Service providers play a crucial role in simplifying the adoption of 3D printing technologies and supporting end users in various medical applications.

System

Systems represent the hardware infrastructure involving 3D printers and related equipment used for the medical applications of 3D printing. While crucial for the execution of printing processes, this ’s dominance is often overshadowed by the importance of the material components used. The increasing number of advanced printing systems capable of handling various materials is likely to promote growth in document technology. However, the effectiveness of these systems is contingent on the success of the materials they work with, making the focus on components like polymers vital for successful entry into the medical market.

Insights On Application

Implant

The implant category, particularly Orthopedic Implants, is expected to dominate the Global 3D Printing in Medical Applications market. This is largely due to the increasing incidence of orthopedic-related ailments globally, which require customized solutions for improved patient outcomes. The ability of 3D printing technology to create patient-specific implants and tools, drastically reducing the lead time for surgical procedures, aligns perfectly with the rising need for personalized medicine. Orthopedic implants are specifically benefiting from advancements in materials and techniques, making them safer and more effective, thus driving higher adoption rates. Additionally, the increasing investments in healthcare technologies further support the market traction in this.

External Wearable Device

The external wearable device category, including hearing aids, prosthetics, and orthodontic products, is gaining momentum in the 3D printing space. The customization offered by 3D printing allows for improved fit and comfort, especially in prosthetics, where personalized designs significantly enhance the user's experience. The rise of an aging population worldwide is also contributing to this demand, as there is a growing need for assistive devices. Moreover, technological advancements in 3D printing are leading to more robust and lightweight devices, encouraging wider adoption among users. These factors position external wearable devices as a significant aspect of the medical applications of 3D printing.

Tissue Engineering

In the realm of tissue engineering, the applications of 3D printing are expanding as researchers focus on creating biocompatible scaffolds for regenerative medicine. The ability to gradually print living cells and biomaterials enables the development of complex tissue structures, which is essential for treating various injuries and diseases. This innovation is crucial, given the increasing global demand for organ transplants. Furthermore, the ability to create intricate designs that mimic natural tissues not only enhances biocompatibility but also encourages indigenous cellular activity. This leads to promising outcomes in tissue repair and regeneration, making this category a noteworthy player in the 3D printing medical applications market.

Clinical Study Device

The clinical study device, encompassing anatomical models and drug testing applications, is critical for advancing medical research and training. Customized 3D models can accurately replicate patient-specific anatomy, aiding in surgical planning and enabling better training for medical practitioners. These models facilitate hands-on practice without risk to patients, enhancing the educational aspect of clinical studies. As regulatory bodies increasingly emphasize the importance of preclinical testing, the utility of 3D-printed models in drug testing protocols is also surging. Consequently, this plays a vital role in improving medical outcomes and ensuring the efficacy of new treatments.

Insights On Technology

Selective Laser Melting (SLM)

The dominating technology within the Global 3D Printing In Medical Applications Market is Selective Laser Melting (SLM). This method stands out due to its ability to produce highly complex geometries and intricate designs in metal parts, making it particularly suitable for medical implants and prosthetics. The growing demand for customized and patient-specific solutions in healthcare drives the adoption of SLM technology, as it offers superior mechanical properties and precision on par with traditional manufacturing methods. Additionally, advancements in materials suitable for SLM and increasing investments in R&D contribute to its anticipated market dominance.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is notable for its capacity to fabricate intricate metal parts directly from CAD data, similar to SLM. While SLM primarily focuses on aluminum and cobalt-chromium alloys, DMLS is versatile and can work with a variety of metals, including titanium, which is critical in the medical field for implants. The technology provides excellent surface finish and mechanical properties, making it ideal for applications like surgical tools and orthopedic implants, which require both durability and precision.

Stereolithography (SLA)

Stereolithography (SLA) excels in producing high-resolution prototypes and models using photosensitive resin. This technology is prevalent for applications where complex geometries and intricate details are paramount, such as dental applications and anatomical models. SLA offers fast turnaround times and exceptional surface finish, which are highly desirable features for medical applications, particularly in prototyping and pre-surgical planning, where detailed models can enhance surgical outcomes.

Electronic Beam Melting (EBM)

Electronic Beam Melting (EBM) uses an electron beam as its source of energy, enabling it to sinter metal powder to create dense parts. This technology is particularly advantageous for manufacturing larger-scale parts that require high strength, such as aerospace components and orthopedic implants. EBM's capability to operate in a vacuum helps in producing higher quality metal parts, which is essential for ensuring biocompatibility in medical applications.

Color Jet Printing

Color Jet Printing is notable for its ability to produce full-color prototypes, making it ideal for applications like anatomical models for education or pre-surgical planning. Although less common for functional parts, the technology excels in visualization and communication. Its use in medical markets is growing, especially in creating patient-specific models that enhance understanding and improve outcomes by allowing for better pre-operative assessments.

Fused Filament Fabrication Technology (FFF)

Fused Filament Fabrication Technology (FFF), also known as Fused Deposition Modeling (FDM), is widely recognized for its affordability and accessibility. This technology enables the use of various thermoplastics, making it suitable for creating prototypes, tools, and educational models in healthcare settings. However, its limitations in achieving the precision and material properties required for final medical-grade products reduce its competitive edge compared to more advanced methods like SLM and SLA.

Two-photon Polymerization (2PP)

Two-photon Polymerization (2PP) is characterized by its capability to produce highly intricate microstructures with sub-micron resolutions. This technology holds significant potential in bioengineering and regenerative medicine, where precise scaffolds for cell growth are necessary. As research progresses, 2PP may find increasing applications in producing customized implants and targeted drug delivery systems, capitalizing on its unique advantages in resolution and detail.

Low-temperature Deposition Manufacturing (LDM)

Low-temperature Deposition Manufacturing (LDM) is an emerging technology primarily focused on bio-printing applications. By enabling the deposition of biological materials at lower temperatures, LDM preserves the viability and functionality of sensitive cells and tissues. This method is increasingly significant in the development of tissue engineering constructs and personalized regenerative therapies, making it a promising contender in the medical 3D printing space.

Laminated Object Manufacturing

Laminated Object Manufacturing involves stacking and bonding layers of materials, which allows for creating large and complex structures. While primarily used for creating prototypes and models, its potential in medical applications is limited. However, it is explored for producing certain non-critical parts and for educational purposes, contributing to medical training tools and basic models.

Multiphase Jet Solidification (MJS)

Multiphase Jet Solidification is a less common technology in the medical domain. It focuses on the production of components by mixing multiple materials delivered in a jet format, which allows for creating complex materials with varying properties. Its applications in the medical field are still largely exploratory, and while it may evolve, it currently holds a fringe position compared to more established technologies like SLM and SLA.

Color Jet Printing

Color Jet Printing (CJP) offers rapid prototyping with full-color capabilities, allowing for the creation of vibrant models crucial for patient engagement and education. This technology permits quick iterations and feedback loops, making it valuable in contexts like surgical planning, where visual aids enhance communication between medical professionals and patients. Despite not producing functional parts, its role in representation and simulation is increasingly valued in the medical sector.

Multi Jet Printing

Multi Jet Printing employs multiple print heads to deliver layers of materials incorporating various colors and textures. This technology is attractive for producing detailed models, especially in medical education and planning, as it can create visually realistic representations of complex anatomical structures. Although it mainly finds use in prototypes, its improvements in speed and quality make it a relevant choice for medical applications involving complex visualizations.

Insights On End User

Medical and Surgical Centers

The Medical and Surgical Centers category is anticipated to be the most influential in the Global 3D Printing In Medical Applications Market. This trend can be attributed to the increasing adoption of advanced technologies in healthcare, which enhances the surgical process through customized implants and prosthetics. The demand for tailored solutions that improve patient outcomes and reduce recovery times is rising. Additionally, many hospitals are investing in 3D printing facilities to create patient-specific models for pre-surgical planning, allowing for greater precision and efficiency. The advancements in materials and printing techniques favor this, confirming its leading position in the market.

Academic Institutions

In the realm of Academic Institutions, there is a notable interest in 3D printing technologies as they serve as hubs for research and innovation. Universities and colleges are increasingly incorporating 3D printing into their curricula to equip future medical professionals with hands-on experience in biotechnology. This plays a crucial role in advancing research in bioprinting, tissue engineering, and the development of new materials. However, while its influence is significant, the practical implementation of these technologies in clinical settings remains limited compared to that in Medical and Surgical Centers.

Pharmaceutical & Biotechnology Companies

Pharmaceutical & Biotechnology Companies are progressively exploring 3D printing for drug development and personalized medicine applications. This sector aims to enhance the efficiency of drug delivery systems and create patient-specific medications. While these innovations hold considerable potential, the adoption rates are moderated by regulatory hurdles and the need for extensive clinical trials to ensure safety and efficacy. Nevertheless, this sector is making strides and is significant in contributing to the evolution of customized treatment solutions, though it does not dominate the market like Medical and Surgical Centers do.

Global 3D Printing In Medical Applications Market Regional Insights:

North America

North America is poised to dominate the Global 3D Printing In Medical Applications market due to several factors, including a robust healthcare infrastructure, significant investment in research and development, and the presence of leading technology companies. The region benefits from advanced manufacturing capabilities, high adoption rates of 3D printing technologies, and strategic collaborations between medical institutions and tech firms. This synergy facilitates innovations in personalized and regenerative medicine, which are driving the demand for 3D printed medical devices and implants. Moreover, a favorable regulatory framework enhances the growth of the 3D printing landscape in North America, making it a leader in this evolving market.

Latin America

Latin America is gradually emerging in the 3D Printing In Medical Applications market, driven by increasing investments in healthcare technologies and collaborations between local universities and companies. However, the growth is impeded by regulatory challenges and varying infrastructure development across countries. Brazil and Mexico lead the market within the region, yet the overall market penetration of 3D printing technologies remains comparatively lower than in North America and Europe. As the region focuses on affordability and accessibility in healthcare, there is potential for increased adoption of 3D printing solutions in medical applications over the coming years.

Asia Pacific

Asia Pacific presents significant opportunities for growth within the 3D Printing In Medical Applications market. Countries like China, Japan, and India are increasingly investing in healthcare technologies and innovations. The rapid urbanization and rising healthcare expenditure in Asia are also accelerating market adoption. However, the market faces hurdles, including inconsistent regulatory standards and the need for advanced training in 3D printing technologies. The region's growing demand for customized medical solutions, particularly in prosthetics and dental applications, indicates future potential, but the current market share is still lagging compared to North America.

Europe

Europe is witnessing steady growth in the 3D Printing In Medical Applications market, supported by strong regulatory frameworks and a focus on innovation within healthcare systems. Countries like Germany and the UK are at the forefront, promoting research initiatives and partnerships in medical 3D printing. However, varying regulations and economic disparities among European nations may slow down the overall market potential. As hospitals and clinics increasingly adopt 3D printing technologies for surgical simulations and custom implants, Europe is likely to augment its presence, yet it remains behind North America in terms of market dominance.

Middle East & Africa

The Middle East & Africa region is currently in the nascent stages of adopting 3D Printing In Medical Applications. While there is growing interest due to the potential for improving healthcare services, the overall market presence remains limited. Factors such as underdeveloped healthcare infrastructure, inadequate investments in medical technologies, and political instabilities hinder market growth. However, countries like the UAE are actively pursuing initiatives to modernize healthcare, which could drive future adoption of 3D printing solutions in the medical field. Overall, while there is potential, significant strides are needed for it to compete with other regions.

3D Printing In Medical Applications Market Competitive Landscape:

Leading entities in the global market for 3D printing applications in medicine are fostering innovation by creating cutting-edge materials and technologies that support customized healthcare solutions. Additionally, they engage in partnerships with healthcare professionals to incorporate 3D printing into clinical workflows, thereby improving patient results and streamlining operations.

The prominent figures in the market for 3D Printing in Medical Applications consist of Stratasys Ltd., 3D Systems Corporation, Materialise NV, Stryker Corporation, Siemens Healthineers, Organovo Holdings, Inc., GE Healthcare, HP Inc., EOS GmbH, and Formlabs. Other notable participants include EnvisionTEC's BioPrinter, Ultimaker, Medtronic, Invivo Therapeutics, Fresenius Medical Care AG, and Aspect Biosystems. Furthermore, contributions come from DENTSPLY Sirona, RWTH Aachen University, Proto Labs, and e-Shape, all of which are significant players in this sector.

Global 3D Printing In Medical Applications Market COVID-19 Impact and Market Status:

The Covid-19 pandemic catalyzed the swift integration of 3D printing technologies within the medical field, driving advancements in the quick design and manufacturing of medical equipment, personal protective gear, and tailored treatment solutions to meet pressing healthcare demands.

The COVID-19 pandemic significantly expedited the use of 3D printing within the medical sector, as healthcare systems encountered extraordinary challenges in fulfilling the immediate need for medical supplies and equipment. Due to issues with shortages, 3D printing emerged as an effective solution for the rapid production of personal protective equipment (PPE), components for ventilators, and other essential devices. This technological advancement allowed hospitals to respond quickly to the crisis and eased the burdens on supply chains. In addition, the pandemic triggered increased investments in research and innovation, leading to more advanced uses of 3D printing in personalized healthcare, including customized prosthetics and tissue bioprinting. Nonetheless, the field still faced obstacles such as regulatory challenges and the necessity for standardization. In summary, the pandemic served as a driving force for the expansion of the 3D printing industry, establishing it as a crucial element of the medical supply network and fostering continuous advancements in the discipline.

Latest Trends and Innovation in The Global 3D Printing In Medical Applications Market:

- In September 2023, 3D Systems announced the acquisition of Aera, a software company specializing in AI-driven healthcare solutions. This acquisition was aimed at enhancing 3D Systems' capabilities in developing personalized medical devices using advanced artificial intelligence technologies.

- In August 2023, Materialise launched its new software platform, Materialise Magics 26, which includes improved features for medical device prototyping and advanced biomodeling. This innovation enables healthcare professionals to create more accurate and patient-specific 3D prints for surgical planning and personalized implants.

- In July 2023, Stratasys and the University of Michigan announced a collaborative research initiative focused on 3D printing biodegradable materials for orthopedic applications. This collaboration aims to develop new materials that can be safely absorbed by the body over time in various surgical applications.

- In June 2023, Stryker Corporation unveiled its latest product line of 3D-printed orthopedic implants, emphasizing enhanced customization for patients through the use of advanced scanning and printing technologies, which aim to improve surgical outcomes.

- In April 2023, Renishaw announced a partnership with the UK’s National Health Service (NHS) to develop a new 3D-printed prosthetic limb service. This initiative targets the rapid production of tailored prosthetics, significantly reducing wait times for patients.

- In March 2023, Formlabs introduced the Form 3B+, a biocompatible 3D printer tailored for dental and medical applications, featuring improved resolution and faster printing speeds. This new model is designed to enhance workflow in healthcare settings, especially in custom dental and surgical applications.

- In January 2023, EOS expanded its medical-focused workforce by hiring additional specialists in biomaterials and medical device certification, aiming to accelerate the development of new 3D printing solutions tailored for the healthcare industry.

- In December 2022, Carbon completed a successful clinical study demonstrating the effectiveness of its 3D-printed surgical guides, which allow for more precise surgical procedures. This achievement positions Carbon as a leader in integrating 3D printing technology into surgical practices.

- In October 2022, ACCU Medical, a podiatry-focused technology company, presented its new kickstarter for custom-fit, 3D-printed orthopedic shoes designed for diabetic patients, showcasing the versatility and advancements in patient-specific medical applications.

3D Printing In Medical Applications Market Growth Factors:

The expansion of the market for 3D printing in healthcare is propelled by technological innovations, a growing need for tailored medical solutions, and an increase in funding for research and development activities.

The market for 3D printing in medical applications is witnessing remarkable expansion, attributed to various crucial elements. Firstly, the swift progression in 3D printing technologies, including bioprinting and advancements in materials science, facilitates the production of intricate, customized medical devices, prosthetics, and implants that cater to the unique requirements of patients. Moreover, the rising demand for individualized healthcare solutions further accelerates the integration of 3D printing for developing personalized surgical tools and anatomical models that enhance pre-operative planning and improve surgical outcomes.

In addition, increased funding and investment in startups and research projects focused on 3D printing drive innovation and expedite market growth. Regulatory organizations are also beginning to formulate more comprehensive guidelines for medical products generated through 3D printing, which strengthens confidence in the market. Furthermore, the healthcare sector's emphasis on cost-effective manufacturing practices highlights the benefits of 3D printing in terms of efficiency, minimizing waste and reducing production timelines. Lastly, the ongoing repercussions of the COVID-19 pandemic have amplified the necessity for swift prototyping and production capabilities within the medical field, fostering a greater dependence on 3D printing technologies for urgent medical resources. Together, these dynamics are propelling the substantial growth of the 3D printing market in medical applications.

3D Printing In Medical Applications Market Restaining Factors:

The expansion of the market for 3D printing applications in the medical field is hindered by several critical factors, such as elevated manufacturing expenses, complex regulatory requirements, and restrictions concerning the compatibility of materials.

The market for 3D printing in the field of medicine encounters various barriers that may hinder its expansion and acceptance. To begin with, the substantial initial investment required for cutting-edge 3D printers and materials may dissuade smaller healthcare facilities and practitioners from adopting this innovative technology. Furthermore, regulatory hurdles persist, as medical devices created through 3D printing must undergo stringent validation and approval protocols, which can result in delays and ened operational expenses. Additionally, concerns related to the physical properties of printing materials, such as biocompatibility and the longevity of the final products, pose significant issues for their use in delicate medical settings. The considerable learning curve for healthcare professionals, coupled with potential resistance to altering established practices, may also impede broader implementation. Moreover, the absence of standardized protocols and best practice guidelines in 3D printing technology generates uncertainty, affecting clinicians' willingness to adopt these advancements. Nonetheless, as technological progress continues and the industry evolves, numerous organizations are making concerted efforts to overcome these obstacles. This could lead to groundbreaking solutions that enhance both efficiency and effectiveness in healthcare delivery, ultimately contributing to a more dynamic and adaptable market in the future.

Segments of the 3D Printing In Medical Applications Market

By Type of Component

• Metals & Alloys

• Ceramics

• Polymers

• Photopolymers

• Thermoplastics

• Services

• System

By Application

• External Wearable Device

? Hearing Aid

? Prosthesis and Orthotics

? Dental Product

• Tissue Engineering

• Implant

? Surgical Guide

? Orthopedic Implant

? Cranio-maxillofacial Implant

• Clinical Study Device

? Anatomical Model

? Drug Testings

By Technology

• Laser Beam Melting

• Selective Laser Melting (SLM)

• Direct Metal Laser Sintering (DMLS)

• Selective Laser Sintering (SLS)

• Droplet Deposition

• Fused Filament Fabrication Technology (FFF)

• Low-temperature Deposition Manufacturing (LDM)

• Multiphase Jet Solidification (MJS)

• Photopolymerization

• Continuous Liquid Interface Production (CLIP)

• Two-photon Polymerization (2PP)

• Stereolithography (SLA)

• Electronic Beam Melting (EBM)

• Laminated Object Manufacturing

• Other

? Color Jet Printing

? Multi Jet Printing

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America