Aircraft Engine Market Analysis and Insights:

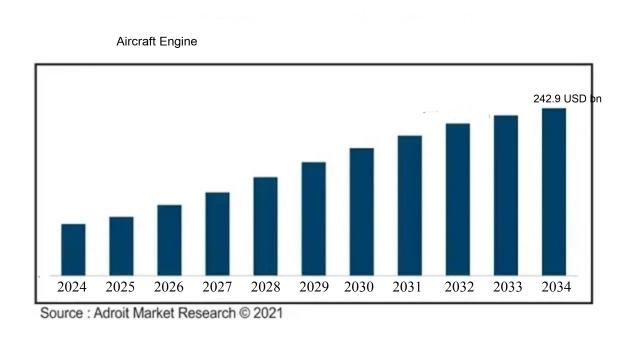

The Global Aircraft Engine Market was estimated to be worth USD 113.9 billion in 2024, and from 2025 to 2034, it is anticipated to grow at a CAGR of 8.19%, with an expected value of USD 242.4 billion in 2034.

The aircraft engine industry is significantly influenced by a number of critical factors, such as the surging demand for air travel, technological advancements, and an increasing emphasis on fuel efficiency and ecological sustainability. The growth in global passenger numbers drives airlines to expand their fleets, leading manufacturers to innovate engines that are both more efficient and powerful. Developments in lightweight materials, enhanced aerodynamics, and hybrid propulsion technologies are not only promoting market expansion but also ensuring lower emissions and reduced operational costs. Additionally, the introduction of stricter regulations targeting the reduction of aviation-related carbon emissions is prompting engine producers to prioritize research and development in cleaner technologies. The growth of cargo transport, particularly accelerated by the boom in e-commerce, is also boosting the need for new engine designs. Together, these elements foster a vibrant landscape for ongoing growth and innovation within the aircraft engine sector.

Aircraft Engine Market Definition

An aircraft engine serves as a propulsion system for an aircraft by producing thrust through the transformation of fuel into mechanical energy. There are several classifications of aircraft engines, such as jet engines and piston engines, each engineered to satisfy distinct performance and efficiency standards.

The aircraft engine is an essential component, functioning as the main propulsion system for planes, which allows them to ascend, navigate, and descend effectively. It transforms fuel into mechanical energy, generating thrust and counteracting gravitational forces that support the aircraft’s weight. The engine's dependability and efficiency are directly linked to safety, operational expenses, and overall flight performance. Innovations in engine technology further improve fuel efficiency and minimize emissions, contributing to worldwide sustainability efforts. Ultimately, the aircraft engine is not only crucial for aviation efficiency but also for environmental impact, solidifying its significance in contemporary air travel.

Aircraft Engine Market Segmental Analysis:

Insights On Type

Turbofan

Turbofan engines are expected to dominate the Global Aircraft Engine Market due to their extensive usage in commercial aviation. Their combination of efficiency and high thrust makes them ideal for large airliners and long-haul flights. The growing demand for fuel-efficient aircraft, coupled with advancements in technology that allow for more powerful and lighter turbofan engines, enhances their appeal. Moreover, these engines are increasingly being adopted in military applications, adding to the overall demand. As the commercial aviation sector continues to expand, particularly in emerging markets, turbofan engines will likely maintain their leading position.

Turboprop

Turboprop engines have a significant presence in regional and short-haul aviation sectors. Their advantages include better fuel efficiency at lower speeds and shorter runways, making them ideal for airlines operating smaller aircraft. As air travel expands in less accessible regions, the demand for turboprop engines remains robust. Additionally, many airlines are investing in turboprop technology to enhance operational efficiency and reduce costs, solidifying their role in niche markets.

Turboshaft

Turboshaft engines primarily serve the helicopter market and some fixed-wing aircraft, playing a pivotal role in military operations, search-and-rescue missions, and private aviation. Their ability to provide power for vertical lift and hover capabilities makes them essential for various applications. The ongoing advancements in aerodynamics and materials are enhancing the performance of turboshaft engines, catering to the increasing demand for reliable and efficient power sources in the aerospace sector.

Piston Engine

Piston engines are mainly used in general aviation and smaller aircraft, serving a niche yet crucial part of the market. With their simplicity and lower operational costs, piston engines are favored for pilot training, recreational flying, and small commuter aircraft. While their market share is limited compared to turbine engines, innovations in piston technology and a resurgence of interest in personal and recreational flying contribute to sustained demand. However, they face challenges against more advanced engine types, which may limit their growth potential.

Insights On Component

Turbine

The turbine component is expected to dominate the Global Aircraft Engine Market due to its critical role in converting thermal energy into mechanical energy, which propels the aircraft forward. Turbines are essential for overall engine performance and efficiency, playing a pivotal role in fuel consumption and emissions reduction. With the increasing demand for more efficient and environmentally friendly engines, advancements in turbine technology, such as the development of high-bypass turbofans and improved aerodynamics, are propelling its significance. Moreover, the steady growth of air traffic globally underlines the need for high-performance turbines, thus securing its leading position in the market.

Compressor

The compressor is a vital component in aircraft engines, responsible for increasing the pressure of the incoming air before it enters the combustion chamber. It significantly affects the engine's overall efficiency and performance, making it instrumental in the development of high-thrust engines. Innovations such as advanced materials and improved design techniques are enhancing compressor performance, contributing to reduced fuel consumption and improved thrust. Given the growing emphasis on fuel efficiency in the aviation industry, the importance of the compressor remains substantial in ensuring optimal engine functionality.

Gearbox

The gearbox manages the power delivery between the engine's turbine and the propeller or fan, enabling efficient operation. As aviation technologies advance, gearboxes are being designed for greater reliability and reduced maintenance needs, which enhances overall aircraft performance. Their capability to adapt to various engine configurations allows for flexibility in design and application, especially in hybrid and electric aircraft. As the demand for novel propulsion systems rises, the gearbox's role in maximizing engine efficiency and durability remains significant for manufacturers in the competitive aviation market.

Exhaust System

The exhaust system plays a crucial role in directing exhaust gases away from the engine while contributing to reducing noise and emissions. With increasing global regulations on noise and pollution, advancements in exhaust technologies are gaining traction. Innovations in this area not only enhance environmental compliance but also positively influence aircraft performance by optimizing exhaust flow dynamics. The progress toward cleaner and quieter engines reinforces the significance of the exhaust system, maintaining its relevance in the demands of modern aviation applications.

Fuel System

The fuel system is essential for storing, controlling, and delivering fuel to the engine in precise amounts. Advances in fuel system technologies are focused on improving efficiency, reducing weight, and enhancing reliability. Additionally, as aircraft design shifts towards alternative fuels and more energy-efficient operations, the fuel system is adapting to support these new fuels and ensure optimal performance. With increasing pressure on airlines to reduce operational costs and comply with environmental standards, the fuel system's role remains vital in the contemporary aircraft engine market.

Others

The "Others" category encompasses various components that, while not dominant, play supportive roles in the aircraft engine ecosystem. This includes systems such as lubrication, cooling, and electrical components that are crucial for overall engine performance and longevity. As aircraft engines become more complex, innovations in these ancillary systems can significantly impact performance and reliability. Although individual components in this category may not lead the market, their collective importance in ensuring efficient engine operation highlights their relevance in the evolving aerospace industry.

Insights on Platform

Unmanned Aerial Vehicles

Unmanned Aerial Vehicles (UAVs) are expected to dominate the Global Aircraft Engine Market due to their rapidly increasing applications across various sectors, including military, commercial, and industrial. The demand for UAVs is largely driven by technological advancements, cost-effectiveness, and improved operational efficiencies. As organizations seek to leverage UAV technology for tasks such as surveillance, delivery, agriculture, and infrastructure inspection, the need for reliable and innovative propulsion systems is becoming critical. Moreover, the growing trend of automation and the rise of smart city initiatives further enhance the necessity of UAVs. As a result, manufacturers are increasingly focusing on developing advanced engines that cater specifically to UAV requirements, positioning this platform as the leading force in the aircraft engine market.

Fixed Wing Aircraft

Fixed Wing Aircraft maintain a significant presence in the aircraft engine market, particularly in commercial aviation. Known for their efficiency and range, these aircraft are widely used for passenger and cargo transportation. The demand for new fixed wing aircraft engines has been fueled by the growing global air traffic and the need for more fuel-efficient and environmentally friendly engines. Additionally, modernization programs and the introduction of next-generation aircraft models also drive investments in the fixed wing . With large commercial airlines focusing on fleet upgrades and the introduction of sustainable aviation fuels, fixed wing aircraft continue to be a robust portion of the market.

Rotary Wing Aircraft

Rotary Wing Aircraft, or helicopters, have a stable share of the aircraft engine market mainly due to their unique capabilities such as vertical takeoff and landing. Their applications span across military, emergency services, and certain commercial uses, including services in hard-to-reach areas. The demand for rotary wing aircraft is sustained by advancements in rotorcraft technology and the requirement for versatile aircraft in search and rescue operations, medical evacuations, and logistics. While their growth may not match that of UAVs, the specific market needs prompt innovations in engine technology, ensuring that rotary wing aircraft remain a vital in the aircraft engine industry.

Insights on Technology

Hybrid

The hybrid technology is expected to dominate the Global Aircraft Engine Market due to its innovative approach towards fuel efficiency and reduced emissions. As airlines and manufacturers are increasingly focused on sustainability and compliance with stringent environmental regulations, hybrid engines offer a viable solution by combining traditional fuel sources with electric power. This blend enhances operational efficiency, reduces overall fuel consumption, and minimizes carbon footprints. Moreover, advancements in battery technology and electric propulsion systems continue to evolve, making hybrid systems more practical and appealing for various types of aircraft. As the industry aims to transition towards greener alternatives, the preference for hybrid technology will clearly lead the market.

Conventional

The conventional technology remains a strong contender in the Global Aircraft Engine Market, primarily due to its established reliability and performance. With years of development and a significant track record, conventional engines are well-understood and widely used in commercial aviation. They are seen as the backbone of current air transport, particularly for long-haul flights where the infrastructure and support systems are already in place. Despite emerging technologies, the dominance of conventional engines continues to stem from extensive global supply chains and maintenance networks, sustaining their foothold while new technologies like hybrid continue to develop.

Global Aircraft Engine Market Regional Insights:

North America

North America is expected to dominate the Global Aircraft Engine market due to its well-established aerospace industry, which includes major manufacturers such as General Electric and Pratt & Whitney. Additionally, the region benefits from significant defense spending, leading to the development of advanced military aircraft engines. The presence of a robust research and development infrastructure further supports innovation and technological advancements in aircraft engines. Strong demand from commercial aviation, coupled with increased air travel post-pandemic, solidifies North America's position. Furthermore, government initiatives and plans to modernize the existing fleet are anticipated to drive growth in the aircraft engine sector in the region.

Latin America

Latin America holds a smaller share of the aircraft engine market compared to more industrialized regions. However, it is gradually expanding, largely driven by the growing demand for domestic air travel and investments in aviation infrastructure. Countries like Brazil have been taking steps to enhance their aerospace capabilities, focusing on manufacturing and maintenance. Although the market is still developing, collaborative efforts with global players could bolster its growth. Nevertheless, political and economic instability in some countries might hinder rapid advancements in this.

Asia Pacific

The Asia Pacific region is witnessing significant growth in the aircraft engine market, primarily due to increasing air passenger traffic and the expansion of low-cost carriers. Countries such as China and India are heavily investing in their aviation sectors, leading to a burgeoning demand for both commercial and military aircraft engines. Additionally, local manufacturers are starting to emerge, offering competitive alternatives to traditional Western brands. However, challenges like regulatory hurdles and supply chain complexities must be navigated for sustained growth in this region.

Europe

Europe has a prominent presence in the Global Aircraft Engine market, driven by key players like Rolls-Royce and Safran. The region is known for a strong emphasis on sustainability and innovation, leading to the development of more fuel-efficient engines to reduce environmental impact. The partnership between aviation manufacturers and regulatory bodies fosters an environment for technological advancements, especially in the context of new EU regulations. However, cautious economic growth and emerging geopolitical tensions could pose challenges for the aircraft engine sector in Europe.

Middle East & Africa

The Middle East & Africa region is experiencing growth in the aircraft engine market, primarily due to expanding airline operations and government investments in aviation infrastructure. Key hubs like Dubai and Qatar have been investing heavily in new aircraft acquisitions, driving demand for engines. However, the market is still emerging, and the infrastructure in some African nations remains underdeveloped. This region faces cultural and economic challenges that might limit its growth compared to other regions, but advancements in air travel could signal future opportunities within its market.

Aircraft Engine Competitive Landscape:

Major contributors to the worldwide aircraft engine sector, including GE Aviation and Rolls-Royce, foster innovation and competitiveness by advancing technological solutions and forming strategic alliances. Their contributions extend beyond production and distribution; they also focus on improving fuel efficiency and promoting sustainability within the aviation industry.

The principal participants in the Aircraft Engine sector comprise General Electric Company, Rolls-Royce Holdings plc, Pratt & Whitney (a of Raytheon Technologies Corporation), CFM International (a collaboration between GE and Safran), Safran S.A., Honeywell International Inc., MTU Aero Engines AG, Woodward, Inc., Engine Alliance (a partnership between General Electric and Pratt & Whitney), International Aero Engines (IAE), Mitsubishi Heavy Industries, Ltd., Williams International, Aero Vodochody, and Turbomeca (a subsidiary of Safran).

Global Aircraft Engine COVID-19 Impact and Market Status:

The Covid-19 pandemic profoundly impacted the global aircraft engine industry, resulting in a substantial drop in the demand for air travel. This downturn led to a decrease in aircraft manufacturing and postponed deliveries of engines.

The COVID-19 pandemic profoundly impacted the aircraft engine sector, mainly due to a notable drop in the demand for air travel. With lockdown measures and travel bans in place, airline operations underwent a dramatic decline, leading to reduced aircraft deliveries and a corresponding decrease in engine manufacturing. Numerous aerospace firms encountered disruptions in their supply chains, resulting in project delays and diminished earnings. Furthermore, the industry experienced ened pressure to enhance sustainability efforts, driving a transition towards technologies that are more fuel-efficient and environmentally sustainable. As restrictions have eased and vaccination rates have risen, a slow recovery is underway, with airlines aiming to upgrade their fleets to improve efficiency and cut costs. Nonetheless, the market is projected to take several years to return to its pre-pandemic state, grappling with persistent issues related to demand variability, supply chain durability, and the necessity for innovation in engine design to comply with imminent regulatory requirements.

Latest Trends and Innovation in The Global Aircraft Engine Market:

- In September 2023, Rolls-Royce announced a partnership with the European Space Agency to develop sustainable technologies for aerospace applications, focusing on hybrid-electric propulsion systems aimed at reducing emissions.

- In August 2023, General Electric Aviation completed the acquisition of Aerion Supersonic, as part of their strategy to advance the development of supersonic jet engines and support the future of high-speed air travel through innovative engine technologies.

- In June 2023, Safran and MTU Aero Engines entered a joint venture agreement to collaborate on the development of the next-generation sustainable aero engines, aiming for a more eco-friendly alternative to conventional engines for narrow-body aircraft.

- In April 2023, Pratt & Whitney unveiled their new GTF Advantage engine, which delivers a 2% increase in fuel efficiency compared to its predecessor, emphasized as a significant advancement in sustainable aviation technology.

- In March 2023, Honeywell announced the successful test of its new hybrid-electric aircraft propulsion system, showcasing the potential for reduced fuel consumption and emissions in future urban air mobility applications.

- In January 2023, Leonardo S.p.A. announced a partnership with Rolls-Royce to co-develop advanced thermal management systems crucial for enhancing the performance of aircraft engines used in military and civil applications.

- In December 2022, United Technologies Corporation (UTC) completed the merger between Raytheon and Pratt & Whitney, creating a more diversified technology and aerospace leader with enhanced capabilities in engine design and manufacturing.

- In November 2022, NASA revealed the successful completion of the Electric Powertrain Flight Demonstration program, collaborating with various industry players including Boeing and GE Aviation, to pave the way for future electric and hybrid propulsion systems in aviation.

- In October 2022, Air France-KLM Group announced a partnership with Safran to jointly explore the development of engines powered by sustainable aviation fuels, aiming to reduce their fleet's carbon footprint significantly by 2030.

Aircraft Engine Market Growth Factors:

The growth of the aircraft engine industry is chiefly propelled by rising passenger air travel, innovative technological developments, and an increasing focus on sustainability and fuel efficiency.

The Aircraft Engine Market is witnessing robust expansion, influenced by several pivotal factors. Primarily, the surge in air travel demand, especially in developing markets, is creating a ened need for new aircraft and subsequently, sophisticated aircraft engines. An increase in passenger traffic and a boom in cargo transport are driving the necessity for engines that are more fuel-efficient and environmentally sustainable, in line with global initiatives aimed at reducing carbon emissions. Furthermore, advancements in technology, including the use of lightweight materials and cutting-edge designs, are significantly improving engine performance and fuel efficiency, making them attractive to airlines seeking to minimize operational expenses.

The movement towards upgrading and retrofitting the current fleet to enhance engine efficiency and adhere to more stringent emissions standards is also promoting market growth. In addition, there is a rising emphasis on electric and hybrid propulsion systems, leading to greater research and development investments, which reflects a transition towards sustainable aviation alternatives. Lastly, increased investments in military aircraft and progress in military engine technologies are playing a vital role in the market's growth. Together, these elements foster a dynamic landscape in the Aircraft Engine Market, propelling innovation and investment to meet the evolving needs of the aviation sector.

Aircraft Engine Market Restaining Factors:

The aircraft engine market faces several significant challenges, including increasing fuel expenses, rigorous environmental compliance standards, and the substantial financial investment necessary for research and development initiatives.

The Aircraft Engine Market is confronted with a number of challenges that could impede its expansion and innovation. Foremost among these are rigorous regulatory standards, which can prolong the certification process for new engines and increase compliance expenditures for manufacturers. Furthermore, the significant capital needed for research and development activities can create financial hurdles, particularly for smaller companies seeking to challenge more established competitors.

The rising emphasis on sustainability and environmental legislation introduces additional complications, necessitating that manufacturers allocate resources towards the creation of greener technologies, including alternative fuels and electric propulsion systems. Supply chain upheavals, often intensified by geopolitical issues and global uncertainties, complicate manufacturing operations and can result in variable material prices. Additionally, the market is often dominated by a limited number of major corporations, which can restrict competition and create barriers for new entrants.

Nevertheless, the sector is experiencing notable technological progress and an increasing demand for engines that are both efficient and environmentally sustainable—fueled by the revival of air travel and the push for modernization. These dynamics foster an environment conducive to innovation and stimulate investment in cutting-edge aerospace technologies, ultimately fortifying the Aircraft Engine Market.

Aircraft Engine Market Key Segments:

By Type

- Turboprop

- Turbofan

- Turboshaft

- Piston Engine

By Component

- Compressor

- Turbine

- Gearbox

- Exhaust System

- Fuel System

- Others

By Platform

- Fixed Wing Aircraft

- Rotary Wing Aircraft

- Unmanned Aerial Vehicles

- By Technology

Conventional

Hybrid

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America