Market Analysis and Insights:

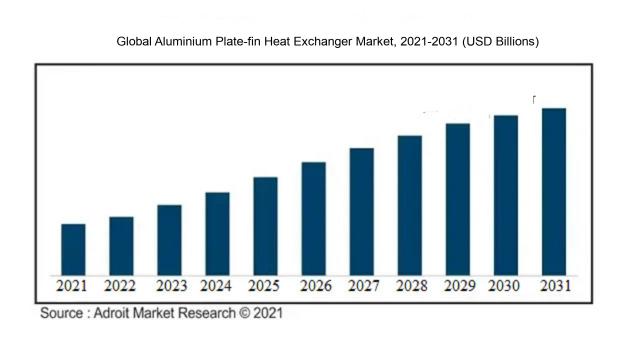

The market for Aluminium Plate-fin Heat Exchanger was estimated to be worth USD XX billion in 2021, and from 2021 to 2031, it is anticipated to grow at a CAGR of XX%, with an expected value of USD XX billion in 2031.

The aluminum plate-fin heat exchanger industry experiences momentum from diverse catalysts. Initially, the surging market demand for heat exchangers across sectors like automotive, aerospace, and oil and gas is propelling market expansion. These sectors necessitate effective heat exchangers to refine operations and curtail energy consumption. Furthermore, the escalating emphasis on energy efficiency and environmental consciousness is steering the preference for aluminum plate-fin heat exchangers. These alternatives boast enhanced heat transfer capabilities and reduced weight relative to traditional copper or steel variants. Additionally, the burgeoning construction sector and the rising requirement for HVAC systems in both commercial and residential complexes are fostering market progression. Aluminum plate-fin heat exchangers find extensive application in HVAC systems owing to their compact design, ened heat transfer efficiency, and resistance to corrosion. Moreover, the mounting investments in renewable energy ventures like wind and solar power are amplifying the demand for heat exchangers within the power generation domain. In essence, the upward trajectory of energy-efficient solutions and the expansion of diverse industries constitute the principal growth stimulants for the aluminum plate-fin heat exchanger sector.

Aluminium Plate-fin Heat Exchanger Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD XX billion |

| Growth Rate | CAGR of XX% during 2021-2031 |

| Segment Covered | By Type, By Application, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Alfa Laval, Linde Engineering, Kelvion, Danfoss, API Heat Transfer, Guntner AG & Co. KG, Hisaka Works Ltd, Xylem, Johnson Controls Inc., Dantherm Group, HRS Heat Exchangers, Kaori Heat Treatment Co., Ltd., Schneider Electric, Modine Manufacturing Company, and EJ Bowman. |

Market Definition

An aluminum plate-fin heat exchanger is a heat transfer mechanism that utilizes aluminum plates equipped with fins to enhance the heat transfer process between two fluid streams, commonly air and a liquid coolant. This device is widely employed across different industries because of its lightweight construction and outstanding thermal conductivity characteristics.

The Aluminum Plate-fin Heat Exchanger is a vital component across multiple industries due to its array of advantageous qualities. This particular heat exchanger is fabricated using aluminum plates organized in a fin configuration, enabling effective heat transfer. The lightweight properties of aluminum contribute to enhanced mobility and simplified installation procedures. Moreover, the corrosion resistance of aluminum allows for widespread application in various environmental conditions. The plate-fin structure offers an extensive surface area for heat exchange, leading to superior thermal efficiency. These heat exchangers find widespread use in sectors like aerospace, automotive, and HVAC for tasks such as engine cooling, gas processing, and thermal regulation. In conclusion, the Aluminum Plate-fin Heat Exchanger's adaptability, resilience, and exceptional performance attributes establish its significance within diverse industrial operations.

Key Market Segmentation:

Insights On Key Type

Porous Fin

Porous Fin is expected to dominate the Global Aluminium Plate-fin Heat Exchanger Market. This part offers a high level of efficiency and heat transfer due to its unique design. The porous structure allows for enhanced airflow and heat dissipation, making it well-suited for applications that require efficient cooling. Additionally, the porous fin design helps to reduce pressure drop, which further enhances the overall performance of the heat exchanger. Manufacturers and customers in industries such as automotive, aerospace, and industrial processes are increasingly adopting Aluminium Plate-fin Heat Exchangers with porous fins to meet their thermal management needs.

Plane Fin

Plane Fin is another significant player in the Global Aluminium Plate-fin Heat Exchanger Market. It is characterized by its simple and flat design, which makes it cost-effective and easy to manufacture. While it may not offer the same level of efficiency as the porous fin, plane fin heat exchangers are still widely used in various industries. They are especially prevalent in applications where cost plays a crucial role. The plane fin design is suitable for heat dissipation in less demanding environments or for systems with lower thermal loads.

Serrated Fin

Serrated Fin is a player that offers improved heat transfer compared to plane fin heat exchangers. The serrated design increases surface area, allowing for enhanced heat dissipation and better performance. This part finds applications in industries where higher cooling capacity is required, such as power generation, chemical processing, and refrigeration. The serrated fin heat exchangers are often favored for their ability to handle higher thermal loads, making them a preferred choice in heavy-duty applications.

Other

The Other in the Global Aluminium Plate-fin Heat Exchanger Market includes any additional types of fins that are not specifically classified as plane fin, serrated fin, or porous fin. These may include specialized fin designs developed for specific applications or experimental designs that are yet to gain widespread adoption. While the other part holds potential for innovation and customization, it is not expected to dominate the market due to its relatively smaller share and restricted applicability. Nonetheless, manufacturers and researchers continue to explore novel fin designs that could potentially disrupt the market in the future.

Insights On Key Application

Defence

Defence is expected to dominate the Global Aluminium Plate-fin Heat Exchanger Market. With increasing global military expenditure and the need for advanced cooling systems for various defence applications, the demand for Aluminium Plate-fin Heat Exchangers in the defence sector is projected to be the highest. These heat exchangers play a crucial role in cooling equipment used in military vehicles, aerospace systems, and other defence applications. The defence sector requires heat exchangers that can withstand extreme conditions and provide efficient heat transfer, making the aluminium plate-fin heat exchangers a popular choice. Furthermore, the growing emphasis on lightweight and high-performance heat exchangers in defence applications further contributes to the dominance of this part.

Air Separation

Aluminum plate-fin heat exchangers are widely used in air separation plants to liquefy and fractionate air into its components like oxygen, nitrogen and argon. The high heat transfer efficiency, large surface area, and light weight of these heat exchangers make them well-suited for the cryogenic temperatures involved in air liquefaction. Plate-fin designs with offset strip fins are commonly used to maximize heat transfer while minimizing pressure drop. Aluminum alloys like 3003 and 6063 are popular choices for their high thermal conductivity and corrosion resistance at low temperatures. As global demand for industrial gases continues to grow, the air separation segment represents a significant and expanding market for aluminum plate-fin heat exchangers.

Petroleum Chemical Industrial

Aluminum plate-fin heat exchangers are also critical components in petroleum refineries and chemical plants. They are used to heat, cool, and condense various hydrocarbon streams during distillation, cracking, and other refining processes. The compact, modular design of plate-fin exchangers allows for flexible configuration to handle the wide range of fluids, temperatures and pressures encountered in these applications. Aluminum is preferred for its corrosion resistance to acidic and alkaline refinery streams. As global energy demand rises, driving capacity expansions at many refineries, the petroleum chemical segment will likely remain a major market for aluminum plate-fin heat exchangers in the coming years.

Power Machinery

The Power Machinery application of the Global Aluminium Plate-fin Heat Exchanger Market is expected to have a moderate level of dominance. Power machinery applications include cooling systems for engines, compressors, turbines, and generators, among others. The need for efficient heat dissipation in power machinery is essential to ensure optimal performance and prevent overheating. Aluminium plate-fin heat exchangers offer high thermal efficiency and compact design, making them suitable for power machinery applications. While this part is significant, it may not dominate the market as strongly as the defence part due to the diverse range of applications and competition from other parts.

Other

The Other application in the Global Aluminium Plate-fin Heat Exchanger Market encompasses various applications not specifically categorized under Air Separation, Petroleum Chemical Industrial, Power Machinery, or Defence. This part includes applications in industries such as automotive, HVAC, refrigeration, and electronics. While there may be a demand for aluminium plate-fin heat exchangers in these industries, the dominance is likely to be limited compared to the other parts mentioned above. The specific requirements and applications in each industry along with competition from alternative heat exchanger technologies may contribute to the relatively lower dominance of this part in the market.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the global aluminium plate-fin heat exchanger market. This region has been experiencing significant growth in various industries such as automotive, power generation, and oil and gas, which are major end-users of aluminium plate-fin heat exchangers. Moreover, the rapid industrialization and urbanization in countries like China and India have led to a high demand for efficient heat transfer solutions, thereby driving the market growth in this region. Additionally, the presence of major aluminium plate-fin heat exchanger manufacturers in Asia Pacific further strengthens its dominance in the global market.

North America

North America holds a prominent position in the global aluminium plate-fin heat exchanger market. This can be attributed to the strong presence of industries such as aerospace, defense, and automobile manufacturing in the region. These industries have a high demand for advanced heat transfer equipment, and aluminium plate-fin heat exchangers offer several advantages such as lightweight, compact design, and high thermal efficiency. Furthermore, strict environmental regulations in North America have boosted the adoption of energy-efficient technologies, including aluminium plate-fin heat exchangers.

Europe

Europe also holds a significant share in the global aluminium plate-fin heat exchanger market. The region is known for its advanced manufacturing capabilities and technological advancements. The automotive industry in Europe, particularly in countries like Germany, France, and Italy, is one of the major consumers of aluminium plate-fin heat exchangers. The increasing focus on reducing CO2 emissions has further propelled the demand for efficient heat transfer solutions, driving the market growth in Europe. Additionally, the presence of key players and ongoing research and development activities in this region contribute to its dominance in the global market.

Latin America

Latin America is a growing market for aluminium plate-fin heat exchangers. The region is witnessing rapid industrialization and infrastructure development, which has increased the demand for heat transfer solutions. The oil and gas, petrochemical, and power generation sectors in Latin America are major end-users of aluminium plate-fin heat exchangers due to their high thermal efficiency and durability. Moreover, government initiatives to attract foreign investments and promote industrial growth have further stimulated the market growth in this region.

Middle East & Africa

The Middle East & Africa region also has a significant presence in the global aluminium plate-fin heat exchanger market. The region's oil and gas industry significantly contributes to the demand for heat transfer equipment, including aluminium plate-fin heat exchangers. The extreme weather conditions and the need for efficient cooling systems in various sectors, such as power generation and industrial manufacturing, also drive the market growth in this region. The expanding infrastructure and construction activities in countries like Saudi Arabia and the United Arab Emirates further contribute to the dominance of the Middle East & Africa in the global market.

Company Profiles:

Prominent participants within the Global Aluminium Plate-fin Heat Exchanger industry are integral in advancing groundbreaking and effective heat exchanger technologies. They focus on enhancing thermal efficiency and delivering tailored solutions to cater to the diverse needs of different sectors.

Prominent companies in the Aluminium Plate-fin Heat Exchanger market comprise Alfa Laval, Linde Engineering, Kelvion, Danfoss, API Heat Transfer, Guntner AG & Co. KG, Hisaka Works Ltd, Xylem, Johnson Controls Inc., Dantherm Group, HRS Heat Exchangers, Kaori Heat Treatment Co., Ltd., Schneider Electric, Modine Manufacturing Company, and EJ Bowman. Their established market presence and innovative efforts have greatly influenced the development of aluminium plate-fin heat exchangers.

COVID-19 Impact and Market Status:

The worldwide aluminum plate-fin heat exchanger sector has experienced notable disruptions caused by the Covid-19 pandemic, resulting in supply chain disturbances, reduced industrial demand, and a contraction in market expansion.

The aluminium plate-fin heat exchanger market has experienced significant disruptions as a result of the global COVID-19 pandemic. The supply chain, manufacturing, and distribution of these heat exchangers have been adversely affected by the crisis. Lockdown measures and travel restrictions across countries have led to a downturn in construction and industrial activities, impacting the demand for aluminium plate-fin heat exchangers. Moreover, the economic slowdown due to the pandemic has caused a decrease in investments in infrastructure projects and consumer spending, further hampering market growth. Despite these challenges, the market is anticipated to gradually recover as economies reopen and industries resume operations. The increasing emphasis on energy efficiency and sustainable solutions is expected to drive the long-term demand for aluminium plate-fin heat exchangers. Market players are implementing strategies to adjust to the new normal, including automation and digitalization, to enhance efficiency and productivity. However, the recovery of the aluminium plate-fin heat exchanger market hinges on factors such as effectively containing the pandemic, government support, and the resurgence of global industrial activities.

Latest Trends and Innovation:

- In January 2020, Johnson Controls, a multinational conglomerate, announced the acquisition of SUMI Air Conditioning, a leading heat exchanger manufacturer, to strengthen its position in the aluminium plate-fin heat exchanger market.

- In August 2020, Modine Manufacturing Company, a global leader in thermal management solutions, introduced a new advanced aluminium plate-fin heat exchanger technology called the MicroChannel Coil (MC3), which offers enhanced performance and energy efficiency.

- In November 2020, Mahle, a German automotive components manufacturer, unveiled its latest aluminium plate-fin heat exchanger for electric vehicles, specifically designed to optimize battery cooling and thermal management.

- In March 2021, Denso Corporation, a major automotive supplier, announced a collaboration with Valeo, a global automotive technology company, to develop high-performance aluminium plate-fin heat exchangers for electric vehicles, aiming to improve battery efficiency and range.

- In May 2021, Alfa Laval, a leading heat transfer, separation, and fluid handling company, launched a new range of compact aluminium plate-fin heat exchangers, designed for various industries including HVAC, power generation, and the process industry.

Significant Growth Factors:

Factors driving the growth of the Aluminium Plate-fin Heat Exchanger Market encompass a surge in the need for cooling systems with high energy efficiency, the continuous expansion of industrial domains, and ened investments in infrastructure modernization.

The Aluminium Plate-fin Heat Exchanger Market is experiencing notable growth propelled by several key factors. Primarily, the escalating need for efficient heat exchange systems across diverse sectors such as automotive, aerospace, and power generation is steering market expansion. Aluminium plate-fin heat exchangers offer distinct benefits including high thermal conductivity, lightweight construction, and corrosion resistance, rendering them well-suited for applications in these industries. Moreover, the escalating emphasis on energy efficiency and sustainability is driving the uptake of plate-fin heat exchangers. These systems facilitate energy conservation by transferring heat between fluids, thereby reducing energy consumption in various processes. Furthermore, the increasing utilization of plate-fin heat exchangers in the expanding LNG sector is further bolstering market growth. Given the efficiency requirements for liquefaction and regasification processes in LNG plants, aluminium plate-fin heat exchangers emerge as a preferred choice for such applications.

Additionally, the surging trend of miniaturization in electronic gadgets and the requisite for effective thermal regulation in these devices are driving the demand for plate-fin heat exchangers. Lastly, supportive governmental policies and regulations that encourage investments in renewable energy and energy-efficient solutions are paving the way for market expansion. To sum up, the noteworthy growth drivers of the Aluminium Plate-fin Heat Exchanger Market can be attributed to the increasing demand across various sectors, the emphasis on energy efficiency, the burgeoning LNG industry, the necessity for thermal management in electronic devices, and the favorable governmental initiatives.

Restraining Factors:

Constraints in the Aluminum Plate-fin Heat Exchanger Industry encompass the elevated costs in comparison to conventional heat exchangers and the necessity for expert maintenance and cleaning.

Numerous factors serve as constraints to the expansion of the Aluminium Plate-fin Heat Exchanger Market. Firstly, the substantial initial capital investment necessary for the design and implementation of these heat exchangers presents a notable obstacle for many small and medium enterprises. Secondly, the intricate nature of the design and production processes poses difficulties for manufacturers, resulting in extended production lead times and elevated expenses. Additionally, the presence of alternative heat exchanger technologies like shell and tube or plate heat exchangers at more economical price points could constrain the demand for aluminium plate-fin heat exchangers.

Moreover, stringent regulations and environmental considerations pertaining to the disposal and recycling of aluminium materials create further impediments to market progression. Lastly, the market's reliance on end-use sectors such as automotive, aerospace, and oil and gas, which are subject to cyclical fluctuations impacting heat exchanger demand, adds another layer of complexity. Despite these inhibiting factors, the aluminium plate-fin heat exchanger market exhibits significant growth potential owing to its superior heat transfer efficiency, light weight, and resistance to corrosion. Ongoing technological advancements and the growing emphasis on energy-efficient solutions across multiple industries present avenues for market expansion. Consequently, by making strategic investments, developing innovative designs, and implementing effective marketing strategies, companies can navigate these challenges and capitalize on the substantial growth opportunities within the aluminium plate-fin heat exchanger market.

Key Segmentation:

Type Overview

• Plane Fin

• Serrated Fin

• Porous Fin

• Other

Application Overview

• Air Separation

• Petroleum Chemical Industrial

• Power Machinery

• Defence

• Other

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America