One of the major reasons propelling the growth of aluminium alloys for the aerospace applications market is the growing need for lightweight materials, high-strength materials in the aerospace sector. Additionally, new alloys with improved mechanical and thermal qualities have been created by manufacturers because to developments in manufacturing technology. Over the course of the projected period, this is anticipated to generate sizable possibilities for aluminium alloys. Furthermore, government regulations to reduce aviation emissions are likely to propel the demand for more efficient engines that require lightweight components made from aluminum alloys. Moreover, rapid urbanization across developing countries coupled with increased disposable income has triggered an increase in air travel activities which is anticipated to further drive the demand for aluminum alloys in the aerospace industry.

The aerospace industry is constantly striving to make air travel efficient, safe, and cost-effective. The need for lightweight materials which are able to offer higher strength and durability is growing by the day. In such a scenario, aluminum alloys offer an ideal solution as they can be used to create complex parts with minimum wastage of material while maintaining their strength and durability.

Aluminum alloys offer several advantages to the aerospace industry such as their strength, lightweight, and corrosion-resistant properties. Furthermore, these alloys are able to maintain their mechanical strength even at high temperatures which makes them an ideal choice for aerospace applications. They also offer excellent workability characteristics which enable manufacturers to create complex shapes with minimal wastage of material. Additionally, aluminum alloys also provide better fuel efficiency due to their lightweight nature thus reducing emissions from airplanes and making air travel more eco-friendly.

Aluminum alloys are a type of metal alloy that contains aluminum as their base material. These alloys are known for their strength, lightweight, and corrosion-resistant properties which make them an ideal choice for aerospace applications such as skin panels, fuselage structures, girders, rotors, propellers, and fuel tanks. Furthermore, these alloys offer excellent workability characteristics which enable manufacturers to create complex shapes with minimal wastage of material.

The aluminum alloys for aerospace applications market offers a variety of services such as manufacturing, research and development, repairs and maintenance, well testing services, and consulting. Manufacturing services include the production of components and parts that meet customer specifications while research and development services involve developing new alloys with improved mechanical and thermal properties. Repairs and maintenance services involve providing solutions to repair and maintain components that have been damaged or worn out due to prolonged usage. Testing services involve testing the quality and performance of aluminum alloys in order to ensure they meet industry standards and customer requirements. Finally, consulting services offer guidance on best practices for using aluminum alloys in aerospace applications.

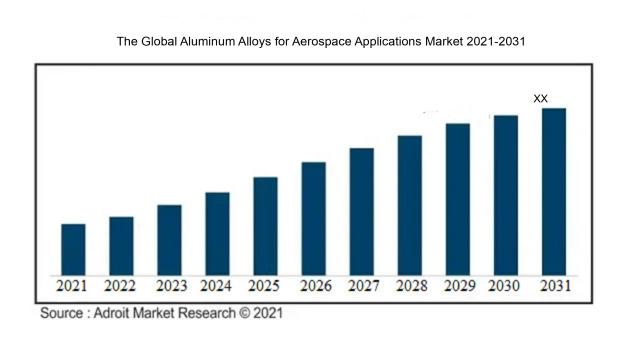

The global aluminum alloys for aerospace applications market are estimated to be valued at USD 67.42 billion in 2021 and is expected to grow at a CAGR of 7.08 % during the forecast period 2021-2031.

The high cost associated with the production and development of these alloys is likely to restrain market growth in the near future. Additionally, technological advancements in alternative materials such as titanium or carbon fiber composites are also seen as a potential threat to market growth. The growing focus on using renewable energy sources as a primary source of power for aircraft is likely to create several opportunities for aluminum alloys for the aerospace applications market. Companies are investing heavily in research and development activities to develop new alloys with higher strength and improved thermal properties that could replace traditional materials such as steel or titanium.

COVID-19 Impact and Market Status

The COVID-19 pandemic has adversely impacted the global aluminum alloys for aerospace applications market due to the temporary suspension of air travel services. Furthermore, the economic slowdown in various countries has also caused a significant decline in demand for commercial aircraft, thereby impacting the market growth. However, increasing investment in research and development activities related to advanced aluminum alloys is likely to provide an impetus to the market over the forecast period. Additionally, companies are focusing on introducing cost-effective solutions that could help them recover from losses incurred during the pandemic. Thus, these initiatives are likely to accelerate market growth by 2031.

Segment Analysis

The 5xxx series Type to Emerge as the Most Lucrative Segment

The 5xxx series aluminum alloys are expected to be the fastest growing segment during the forecast period due to their superior properties such as high strength, corrosion resistance, and lightweight. These alloys are used in aircraft structural components such as fuselage frames and wing ribs. Furthermore, they are also used in aircraft engines, landing gear systems, and fuel tanks.

The Most Popular Application Segment is the skin

The application of aluminum alloys for the aerospace applications market is expected to be led by the skin segment during the forecast period. The increasing demand from the military and commercial aviation sectors for lightweight components is likely to drive the growth of this segment. Additionally, these alloys are preferred over other materials such as titanium due to their superior strength-to-weight ratio.

Transportation to Ensure Revenue Maximization

The transportation segment is expected to be the fastest-growing end-use during the forecast period. This can be attributed to the rising demand for passenger air travel and commercial aircraft, as well as increasing investments in military programs. Furthermore, there is generally a greater preference for aluminum alloys over other materials such as carbon fibers or titanium due to their cost-effectiveness and lightweight properties which make them ideal for aerospace applications.

The Asia Pacific (APAC) region to render Adequate Financing Avenues

The Asia Pacific region is expected to account for the largest share of the global aluminum alloys for aerospace applications market during the forecast period. This can be attributed to the increasing demand from countries such as China, India, and Japan. The growing aircraft fleet size in these countries is expected to drive the demand for aluminum alloys in this region. Additionally, government initiatives to promote air travel and investments in research & development activities are likely to boost market growth.

The major players in the aluminum alloys for the aerospace applications market are Alcoa Inc., Norsk Hydro, Novelis Corporation, Constellium NV, Rio Tinto Plc., and Hindalco Industries Limited. These companies offer a wide range of products to meet the needs of the aerospace industry. The focus on developing new alloys with improved mechanical and thermal properties is expected to be a key trend in the market during the forecast period. Companies are investing heavily in research and development activities in order to develop new alloys that could offer higher strength and durability while maintaining their lightweight nature.

Recent Developments in the Aluminum Alloys for Aerospace Applications Market

• Aeromet International Limited has launched a full-scale R&D program to develop an advanced line of high-strength aluminum alloys that could be used in aircraft.

• Noteworthy developments in this space include collaboration between Oerlikon Metco and Alcoa Corporation for their joint venture project "VAP3X " and the introduction of Alcoa's new high-strength aluminum alloy AA 4750 by Kobe Steel. Such innovative developments are likely to drive the market in the near future.

Aluminum Alloys for Aerospace Applications Market Scope

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018- 2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD 67.42 billion |

| Growth Rate | CAGR of 7.08 % during 2021-2031 |

| Segment Covered | by Type, By Application, By End-User, Regions |

| Regions Covered | North America, Europe, Asia Pacific, Middle East and Africa, South America |

| Key Players Profiled | Alcoa Inc., Norsk Hydro, Novelis Corporation, Constellium NV, Rio Tinto Plc., and Hindalco Industries Limited |

Key Segments of the Global Aluminum Alloys for Aerospace Applications Market

Type Overview (USD Billion)

- 2xxxSeries

- 3xxx Series

- 5xxx Series

- 6xxx Series

- 7xxx Series

- Others

Application Overview (USD Billion)

- Skin

- Fuselage Structure

- Girder

- Rotor

- Propeller

- Fuel Tank

- Other

End-User Overview (USD Billion)

- Transportation

- Building & Construction

- Machinery

- Automotive

- Aluminum Alloys Market and Marine

Regional Overview (USD Billion)

North America

- U.S

- Canada

Europe

- Germany

- France

- UK

- Rest of Europe

Asia Pacific

- China

- India

- Japan

- Rest of Asia Pacific

South America

- Mexico

- Brazil

- Rest of South America

Middle East and South Africa

- UAE

- South Africa