Aluminum Honeycomb Market Analysis and Insights:

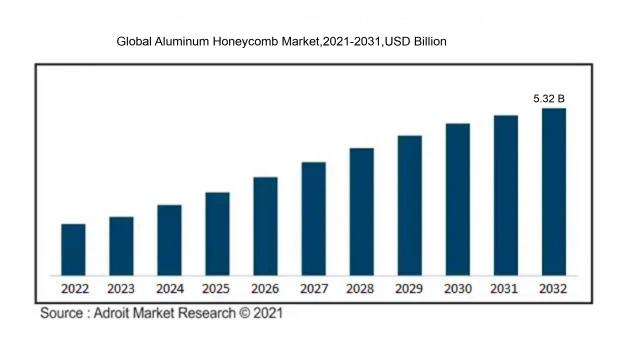

In 2023, the size of the worldwide Aluminum Honeycomb market was US$ 3.26 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 5.39 % from 2024 to 2032, reaching US$ 5.32 billion.

The Aluminum Honeycomb Sector experiences growth driven by several pivotal factors. Primarily, the rising need for lightweight yet robust materials within the aerospace, automotive, and construction industries substantially fuels market expansion. These sectors are increasingly focused on materials that not only improve fuel efficiency but also minimize emissions, making the aluminum honeycomb's exceptional strength-to-weight ratio a valuable asset. Furthermore, the ened emphasis on sustainability and the recyclability of materials complements aluminum’s eco-friendly properties, encouraging its widespread use in multiple applications. Advances in manufacturing technologies also play a critical role in enhancing product quality and reducing costs, thereby broadening the accessibility of aluminum honeycomb for various purposes. In addition, the surge in commercial construction projects and the drive for energy-efficient structures intensify the demand for innovative materials, including aluminum honeycomb panels. Finally, the implementation of regulatory standards that call for elevated performance and safety in materials creates further market potential, establishing aluminum honeycomb as an optimal choice across numerous industries.

Aluminum Honeycomb Market Definition

Aluminum honeycomb is an innovative composite material characterized by a core structure of hexagonal cells, which is encased between two slim aluminum layers. This material is favored across various sectors, including aerospace, automotive, and construction, for its remarkable balance of strength and lightweight properties, alongside its impressive durability.

Aluminum honeycomb plays an essential role across a range of industries, thanks to its remarkable strength-to-weight ratio and adaptability. This lightweight composite comprises a honeycomb core encased in aluminum sheets, delivering outstanding structural integrity while keeping weight to a minimum. Its usage extends to sectors like aerospace, automotive, and construction, where weight reduction directly contributes to improved fuel efficiency and overall performance. Moreover, aluminum honeycomb features excellent thermal insulation properties, effective sound absorption, and significant resistance to corrosion, rendering it suitable for high-performance applications. The material's ability to be recycled enhances its environmental sustainability, aligning well with contemporary green initiatives, and establishing it as a crucial element in cutting-edge engineering and design across various fields.

Aluminum Honeycomb Market Segmental Analysis:

Insights On Application

Architectural and Building Panels

The dominating area within the Global Aluminum Honeycomb Market is the Architectural and Building Panels. This dominance can be attributed to the increasing demand for lightweight and durable materials in construction, where aluminum honeycomb offers exceptional strength-to-weight ratios. Architects and builders are increasingly opting for aluminum honeycomb panels due to their significant advantages, such as thermal insulation, sound absorption, and fire safety, which meet stringent regulatory standards. Moreover, as urbanization continues to accelerate, the need for innovative building materials that enhance efficiency and aesthetics is paramount, further solidifying the position of architectural and building panels in this market.

Floor Structures and Stairways

The Floor Structures and Stairways category is notable for its application of aluminum honeycomb due to its excellent structural properties. The lightweight nature of aluminum honeycomb makes it an ideal candidate for flooring solutions that require both strength and minimal weight, ensuring easy installation and efficiency in load-bearing capacities. This application finds utility in high-rise buildings and commercial spaces where architects aim to maximize usable space while keeping the structural integrity intact. As the construction sector focuses more on sustainability, the demand for innovative materials in flooring will likely see gradual growth.

Energy Absorption

Energy Absorption is an important category where aluminum honeycomb structures provide significant benefits, particularly in the automotive and aerospace industries. This application focuses on the ability of aluminum honeycomb to dissipate energy efficiently during impact, thereby enhancing safety. Products such as crashworthy components and protective structures leverage this functionality. As safety standards continue to rise in various industries, the importance of energy absorption technology will foster developments and innovation, leading to a steady demand for aluminum honeycomb in specialized applications.

Others

The Others category encompasses diverse applications of aluminum honeycomb that do not fall strictly under the primary s. This includes uses in transportation interiors, packaging solutions, and decorative elements, among others. While these applications may not dominate the market, they play a vital role in expanding the reach of aluminum honeycomb materials across multiple industries. The versatility of aluminum honeycomb allows it to be fabricated into various shapes and sizes, catering to niche s that require customized solutions, thereby strengthening brand presence and staying competitive in the evolving market landscape.

Insights On End User

Aerospace & Defense

The Aerospace & Defense sector is expected to dominate the Global Aluminum Honeycomb Market due to its substantial demand for lightweight materials that offer exceptional strength-to-weight ratios. Aluminum honeycombs are used extensively in aircraft interiors, wings, and other components where weight reductions are critical for improving fuel efficiency and overall performance. Additionally, stringent regulations and standards for safety and performance in this industry further drive the adoption of advanced materials. The growth of air travel and the increasing number of defense contracts globally also contribute to the rising demand for aluminum honeycomb structures, positioning this sector as the leader in the market.

Automotive

The Automotive industry is witnessing a growing interest in aluminum honeycomb materials due to the increasing emphasis on fuel efficiency and sustainability. These materials are being used in various automotive applications, including body panels, chassis components, and interior structures, to reduce weight without compromising safety. As manufacturers strive to meet stricter emissions regulations and consumer demands for lightweight vehicles, the utilization of aluminum honeycomb is expected to grow, yet it remains second to the aerospace sector.

Marine

In the Marine industry, aluminum honeycomb materials are utilized for applications such as boat hulls and interiors, ensuring durability and strength while being lightweight. The push for more fuel-efficient vessels drives demand in this area, although it significantly lags behind aerospace requirements. As recreational and commercial boating grows, the demand for advanced materials is likely to increase, but it will not overshadow the aerospace sector's dominance.

Building & Construction

The Building & Construction sector is gradually incorporating aluminum honeycomb materials into its designs, primarily for facades, insulation panels, and lightweight structural elements. These materials offer insulation and strength benefits, complementing modern architectural styles. However, while this sector is growing, it does not match the rapid expansion being seen in the aerospace domain, which largely dictates the trends in the aluminum honeycomb market.

Energy

In the Energy sector, aluminum honeycomb materials find usage in applications such as solar panel mounts and structural components in wind turbines. The growing focus on renewable energy sources drives marginal growth in this area. However, its contribution to the overall aluminum honeycomb market remains minimal compared to the significant demands of aerospace.

Transportation

The Transportation industry employs aluminum honeycomb primarily in packaging and lightweight freight applications. This benefits from the material's ability to enhance transport efficiency. Despite its useful applications to lighten loads, the transportation market does not dominate the aluminum honeycomb sector as significantly as aerospace and defense, limiting its overall impact on the market.

Others

In the Others category, which encompasses various niche applications such as consumer goods and industrial equipment, aluminum honeycomb materials are occasionally utilized for their environmental benefits and lightweight properties. Nevertheless, this sector holds a minor share of the market, overshadowed by the aforementioned sectors, particularly aerospace and defense, which are the primary driving forces behind aluminum honeycomb material demand.

Global Aluminum Honeycomb Market Regional Insights:

Asia Pacific

The Asia Pacific region is projected to dominate the Global Aluminum Honeycomb market due to several factors, including rapid industrialization, increasing construction activities, and a growing automotive sector. Countries such as China and India exhibit significant demand driven by their booming aerospace, transportation, and construction industries, where lightweight and high-strength materials are essential. The region's strong manufacturing capabilities, availability of raw materials, and favorable government policies further contribute to its leading position in the market. Additionally, the rising awareness of energy efficiency and sustainable materials among end users in this area solidifies Asia Pacific's dominance.

North America

North America is a strong contender in the Global Aluminum Honeycomb market, driven primarily by a well-established aerospace and defense industry that seeks lightweight materials for improved fuel efficiency and performance. Moreover, increasing preference for eco-friendly materials in construction and transportation is bolstering growth. The United States and Canada are at the forefront of innovations in aluminum honeycomb applications, with substantial investments in research and development fueling advancements in product quality and performance.

Europe

Europe ranks as a significant market for aluminum honeycomb, primarily due to stringent regulations promoting lightweight and energy-efficient building materials. The automotive and aerospace sectors in countries like Germany and France are increasingly adopting aluminum honeycomb structures for their lightness and durability. Additionally, there is a growing trend toward sustainable and recycled materials in the construction industry, further supporting market growth in this region. Innovations in design and applications are also expected to create new avenues for growth.

Latin America

The Latin American market for aluminum honeycomb is gradually emerging, driven by modest industrial growth and increasing infrastructure projects. Countries such as Brazil and Mexico are showing potential for growth in sectors such as transportation and infrastructure, where light and durable materials are needed. However, challenges such as economic volatility and less developed manufacturing capabilities compared to other regions might hinder faster growth. The market is still in a developmental stage but has room for significant advancements as investment in construction and industrialization increases.

Middle East & Africa

The Middle East & Africa region is currently experiencing growth in the aluminum honeycomb market, propelled by a surge in infrastructure projects and construction activities linked to urbanization efforts. Countries like the UAE and South Africa are showing interest in adopting lightweight and robust materials for their construction and aerospace sectors. However, the growth is tempered by economic fluctuations, political instability, and limited local manufacturing capacities. As investments in technology and infrastructure continue, the region may see potential growth in specific niches of the aluminum honeycomb market.

Aluminum Honeycomb Market Competitive Landscape:

Major participants in the Global Aluminum Honeycomb sector encompass producers and vendors who propel innovation and advance product development, all the while maintaining rigorous quality and sustainability benchmarks. Their collaborative alliances and initiatives for market growth play a crucial role in shaping industry expansion and fostering consumer acceptance.

Prominent participants in the Aluminum Honeycomb Market encompass Arconic Inc., Hexcel Corporation, Alucoil, The Gill Corporation, AMT Composites, Merlini, YUSUNG, COREX, Aluminium L.A., and KARS. Furthermore, other significant firms include Kappa Structural, Layne, Pacific Coast Composites, Toray Advanced Composites, and Sapa Group, which is currently integrated with Norsk Hydro. Additionally, Future Metal Docks and GMS Composites also play a role in this sector.

Global Aluminum Honeycomb Market COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly impacted the worldwide aluminum honeycomb industry, leading to disruptions in supply chains and a decline in demand from essential sectors like aerospace and construction.

The aluminum honeycomb industry faced considerable challenges during the COVID-19 pandemic, primarily due to interruptions in supply chains, diminished production capabilities, and a slump in demand from sectors including aerospace, automotive, and construction. Measures such as lockdowns and social distancing resulted in factory shutdowns, workforce shortages, and logistical hurdles, which adversely affected the procurement of raw materials and delivery schedules. Although certain industries experienced a decline in the use of aluminum honeycomb products, the rising need for lightweight and efficient materials, particularly in the transportation and renewable energy sectors, helped maintain some stability. As global economies slowly rebound and adjust to new operational standards, the market is anticipated to recover, fueled by a ened emphasis on sustainable materials and innovations in manufacturing techniques. In summary, while the pandemic introduced immediate obstacles, it simultaneously paved the way for growth opportunities in specialized applications and technological advancements within the aluminum honeycomb industry.

Latest Trends and Innovation in The Global Aluminum Honeycomb Market:

- In June 2023, Hexcel Corporation announced the expansion of its aluminum honeycomb manufacturing capabilities with a new facility in the United States, aimed at increasing production capacity to meet rising demand in aerospace applications.

- In March 2023, Arconic Corporation completed the acquisition of a leading specialty aluminum products company, which bolstered its portfolio in the lightweight materials sector and enhanced its aluminum honeycomb offerings for automotive and aerospace clients.

- In July 2022, Aluminum Company of America (Alcoa) introduced a new range of aluminum honeycomb materials designed for improved energy efficiency and thermal insulation, particularly targeting the building and construction markets.

- In January 2022, Omegabond Technologies partnered with a major aerospace manufacturer to develop high-performance aluminum honeycomb structures with enhanced fire resistance and weight reduction properties for upcoming aircraft models.

- In October 2021, the company AIREX AG was acquired by a prominent aerospace composites manufacturer, aiming to integrate advanced aluminum honeycomb technology into its product offerings and expand into new markets.

- In February 2021, Murray & Roberts announced a strategic alliance with the Israel-based company, Airolec Advanced Systems, to co-develop aluminum honeycomb solutions specifically tailored for the defense and security sector.

- In November 2020, Kordsa Teknik Tekstil A.S. and one of its affiliates launched a new line of aluminum honeycomb core materials, significantly increasing their capabilities in providing lightweight and strong composite materials for various industrial applications.

Aluminum Honeycomb Market Growth Factors:

The Aluminum Honeycomb Market is witnessing expansion, propelled by a rising need in the aerospace and automotive sectors for lightweight and durable materials that improve fuel efficiency and lower emissions.

The aluminum honeycomb sector is witnessing substantial expansion due to multiple influential factors. To begin with, there is a rising demand for lightweight yet robust materials across various industries, including aerospace, automotive, and construction, as businesses aim to improve fuel efficiency and minimize emissions. Additionally, the material's superior thermal and sound insulation capabilities make it a preferred option for use in transportation and architectural projects.

The surge in investments directed toward infrastructure development, especially in developing nations, is further stimulating the requirement for aluminum honeycomb products. Concurrently, advancements in manufacturing techniques are enhancing the quality of these panels while lowering their production costs, thus broadening their market appeal.

Moreover, the environmentally friendly nature of aluminum, particularly its recyclability, is gaining importance as industries strive for sustainable solutions. The increasing adoption of composite materials across various sectors also plays a part in this market's growth, as aluminum honeycombs prove to be efficient core materials that bolster structural integrity.

In summary, the convergence of technological innovations, expansion in crucial sectors, and a movement towards sustainable materials is solidifying the positive trajectory of the aluminum honeycomb industry.

Aluminum Honeycomb Market Restaining Factors:

The Aluminum Honeycomb Market faces significant challenges due to elevated manufacturing expenses and growing rivalry from other lightweight material alternatives.

The Aluminum Honeycomb Market is confronted with various challenges that could hinder its growth prospects. A primary issue is the volatility in raw material prices, especially aluminum, which can create unpredictable production expenses and influence profit margins. Moreover, the substantial capital investment needed for manufacturing equipment and advanced technologies can discourage new market participants and restrict industry growth.

There exists a general lack of understanding about the advantages of aluminum honeycomb products, particularly among smaller businesses in emerging markets. Additionally, environmental issues associated with aluminum mining and processing may result in regulatory challenges that could disrupt production workflows.

The threat from other materials, such as composite structures and conventional honeycomb alternatives, is significant, as these options might provide cost efficiencies or unique performance features. Furthermore, the market's reliance on sectors like aerospace, automotive, and construction makes it susceptible to economic fluctuations that can impact these industries.

Nevertheless, continuous advancements in aluminum honeycomb production techniques and its rising use in lightweight construction applications offer a hopeful outlook. Industry stakeholders are actively seeking innovative and eco-friendly uses for this adaptable material.

Segments of the Aluminum Honeycomb Market

By Application

• Architectural and Building Panels

• Floor Structures and Stairways

• Energy Absorption

• Others

By End User

• Aerospace & Defense

• Automotive

• Marine

• Building & Construction

• Energy

• Transportation

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America