Benzene Market Analysis and Insights:

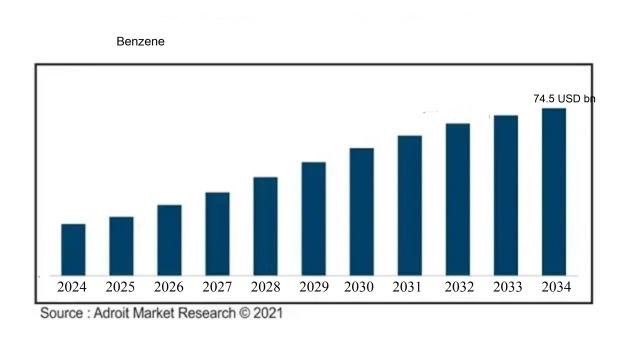

The market for Benzene was estimated to be worth USD 43 billion in 2024, and from 2025 to 2034, it is anticipated to grow at a CAGR of 5.2%, with an expected value of USD 74.5 billion in 2034.

The benzene market is primarily influenced by several critical elements, including industrial requirements, regulatory policies, and technological innovations. The surge in the production of chemicals like styrene, phenol, and cyclohexane, which rely on benzene as a crucial raw material, drives market growth. Regulatory initiatives aimed at minimizing environmental effects and encouraging sustainable chemistry practices may also modify production techniques and sourcing strategies. Moreover, technological advancements that improve the efficiency of benzene extraction and processing can offer competitive edges in the market. Price fluctuations in crude oil, along with geopolitical factors affecting supply chains, can introduce volatility in benzene pricing, further impacting market dynamics. In summary, the benzene market is molded by the interplay of demand, regulatory influences, and the need to adapt to evolving technological trends.

Benzene Market Definition

Benzene is a clear, combustible liquid characterized by a sweet fragrance, widely utilized as an industrial solvent and in the production of numerous chemical compounds. As a fundamental aromatic hydrocarbon, its chemical formula is C6H6, distinguished by its stable and distinctive cyclic structure.

Benzene is a vital organic compound that plays a key role as a foundational component in the manufacture of numerous chemicals and materials. It functions as a solvent in industrial applications and is indispensable in the creation of polymers, plastics, and synthetic fibers, including nylon and polyester. Moreover, benzene acts as a precursor for significant chemicals such as styrene, phenol, and cyclohexane, which are crucial for the production of resins, dyes, and pharmaceuticals. Its distinctive chemical composition affords it diverse reactivity, rendering it essential to organic chemistry and various manufacturing industries, highlighting its importance in contemporary industry and daily consumer products.

Benzene Market Segmental Analysis:

Insights On Derivative

Cumene

The dominating part of the Global Benzene Market is expected to be Cumene. This can be attributed to its significant application in the production of phenol and acetone, both of which are fundamental chemicals used in various industries, including plastics and pharmaceuticals. As the demand for these chemicals continues to soar, driven by industrialization and consumer products, Cumene’s importance grows. Furthermore, the rise of eco-friendly practices and sustainable chemicals boosts the use of Cumene in bio-based derivatives, making it a focal point in the benzene market. This trend is anticipated to further strengthen its market position in the coming years.

Ethylbenzene

Ethylbenzene is another important derivative within the benzene market, primarily utilized in the manufacturing of styrene, which is a key component in producing various polymers and plastics. The demand for styrene continues to rise due to its applications in construction materials, packaging, and automotive components. Additionally, Ethylbenzene benefits from a well-established supply chain and production processes, supporting its steady market presence. However, while it holds a significant market share, its growth potential may be overshadowed by Cumene, which is positioned more favorably due to growing markets for phenol and acetone.

Alkylbenzene

Alkylbenzene is primarily utilized in the production of surfactants, widely employed in both household and industrial cleaning products. This sector is growing fast, driven by increased consumer demand for cleaning agents and detergents. However, Alkylbenzene faces stiff competition from other derivatives like Cumene, which are benefiting from more diversified applications in high-demand industries, such as pharmaceuticals. The growth of Alkylbenzene is contingent on market trends in cleaning products and could face fluctuations based on consumer preferences, impacting its dominance in the benzene market.

Cyclohexane

Cyclohexane is predominantly used in the production of nylon and other synthetic fibers, essential for the textile and automotive industries. With the rise in demand for lightweight materials in numerous applications, Cyclohexane maintains a stable niche in the market. However, its growth potential is limited compared to Cumene, which has broader applicability in chemicals that are in high demand. Thus, while Cyclohexane remains vital for specific sectors, its overall market influence is relatively constrained compared to the leading derivatives.

Nitrobenzene

Nitrobenzene is primarily utilized in the manufacture of aniline and other chemicals, serving as a critical component in dyes, fragrances, and certain plastics. Although its applications are diverse, Nitrobenzene’s growth is restricted due to regulatory concerns over its toxicity and potential environmental impact. The emergence of more sustainable and less harmful alternatives could hinder its market expansion. Hence, while it plays a role in the benzene derivatives market, its growth is not as robust as that of Cumene or other derivatives that are experiencing strong demand growth.

Others

The "Others" category encompasses various lesser-known derivatives of benzene, such as phenylacetylene and dodecylbenzene. While these derivatives may serve specialized applications in niche markets, they do not contribute significantly to the overall benzene market compared to the more prominent types like Cumene and Ethylbenzene. The slow growth and relatively small market share of these alternatives limit their impact within the broader landscape of the benzene derivatives industry. Consequently, their significance pales in comparison to more widely utilized derivatives emerging in the market.

Insights On Manufacturing Process

Toluene Disproportionation

Toluene Disproportionation is expected to dominate the Global Benzene Market due to its efficiency in converting toluene, which is a readily available feedstock, into benzene and xylene. This process is favored for its economic viability and lower operational costs compared to other methods. The increasing demand for benzene derivatives in industries such as petrochemicals, pharmaceuticals, and automotive fuels further drives the preference for this manufacturing technique. As benzene remains integral for producing styrene, phenol, and aniline, the toluene disproportionation method offers a sustainable pathway to meet the rising global demand.

Catalytic Reforming

Catalytic Reforming is a well-established method primarily used in oil refineries to enhance the quality of gasoline components while producing valuable aromatics like benzene. The adoption of this process is supported by advancements in catalyst technology that increase yield efficiency and selectivity for benzene production. Despite facing competitive pressure from other methods, this processing line continues to be significant due to its integration within refinery operations, ensuring consistent supply and the ability to adjust to fluctuating demands in aromatic hydrocarbons.

Toluene Hydrodealkylation

Toluene Hydrodealkylation serves as an alternative technique that converts toluene directly into benzene. While this method produces a considerable yield of benzene, it has not gained as much traction as toluene disproportionation. The high-energy requirements and the complexity of the process are significant drawbacks. Nonetheless, this method maintains relevance in specific applications where high purity benzene is necessary. Its adoption may vary depending on technological improvements aimed at reducing energy consumption.

Pyrolysis

Pyrolysis is mainly associated with breaking down complex organic materials, commonly employed in the production of biofuels. In terms of benzene production, pyrolysis is utilized in converting biomass or plastic waste into aromatic compounds. It presents an environmentally friendly approach, tapping into renewable feedstocks. However, its market share in the global benzene production landscape is limited compared to other methods due to the relatively higher costs and lower efficiency for benzene yield.

Steam Cracking of Naphtha

Steam Cracking of Naphtha is a prevalent industrial process used to produce ethylene, propylene, and other light hydrocarbons. While its contribution to benzene production is significant, it is primarily known for the production of lighter olefins. In recent years, improvements in the process have allowed for better benzene yields, but the overall push towards lighter products in the petrochemical market limits its role. Nevertheless, the integration of steam cracking within broader petrochemical facilities positions it as a viable method for maintaining benzene supply.

From Biomass

The route of generating benzene From Biomass is gaining attention due to its sustainable nature. Transforming biomass into chemicals like benzene contributes to reducing the carbon footprint associated with traditional fossil fuel processes. Despite the environmental benefits, scalability and economic feasibility remain challenges in this method’s broader adoption. Ongoing research aims to enhance the conversion efficiencies, but, at present, it occupies a small niche within the overall benzene production landscape.

Insights On Application

Chemical Intermediates

The Chemical Intermediates application is expected to dominate the Global Benzene Market due to its crucial role in producing a wide range of chemicals vital for several industries. Benzene is fundamental in synthesizing various important compounds including aniline, phenol, and cyclohexane, which are key components in pharmaceuticals, agrochemicals, and adhesives. The continuous demand from these sectors drives the need for benzene as a primary raw material, making Chemical Intermediates a leading category. The growth in chemical manufacturing and advancements in technology further enhance the significance of this, assuring its dominance in the market landscape.

Plastics

The Plastics application significantly contributes to the benzene market as benzene derivatives are essential for producing styrene, which is a vital component in making polystyrene. The increasing demand for lightweight and durable plastics in automotive, packaging, and consumer goods sectors is fuelling this growth. Innovations in plastic production and a shift towards sustainable materials are also influencing plastic manufacturers to rely on benzene-based polymers, thereby sustaining the market interest in this application.

Solvent

In the Solvent category, benzene is often used for its exceptional solvency properties in formulations for coatings, paints, and varnishes. The demand for high-performance solvents is growing, particularly in the automotive and construction industries, where quality finishes are crucial. However, increasing regulations regarding volatile organic compounds (VOCs) may pose challenges for this sector, yet the persistent application of benzene in specialized solvent products helps maintain its prominence.

Surfactants

Surfactants produced using benzene derivatives are vital for various household and industrial applications, including cleaning agents and personal care products. The growing consumer inclination toward effective and eco-friendly cleaners is spurring innovation in surfactant formulations. The versatility of benzene in creating various surfactants that provide superior performance in different environments makes this category a noteworthy player in the benzene market.

Rubber Manufacturing

The Rubber Manufacturing sector utilizes benzene in the production of synthetic rubber, which is prevalent in tires, footwear, and other industrial applications. With a notable rise in automotive production and infrastructure development worldwide, the demand for synthetic rubber is expected to fulfill the market needs. This, driven by performance requirements and specialized applications, underscores the critical role of benzene in enhancing rubber properties.

Detergents

In Detergents, benzene derivatives are utilized to formulate effective cleaning agents providing excellent stain removal and performance. As more consumers focus on the cleaning efficiency and environmental sustainability of laundry and dishwashing products, innovations in detergent formulations using benzene compounds are likely to emerge. This sector’s growth aligns with increasing household expenditure on cleaning products, which sustains its relevance in the benzene market.

Explosives

While more niche in volume, the Explosives application utilizes benzene in the production of essential compounds like TNT. The demand for explosives is driven primarily by mining, construction, and defense industries. Although not the largest consumer of benzene, the explosives ’s consistent demand ensures a steady market for benzene as a precursor. Factors affecting regulations in this area could influence its market dynamics.

Lubricants

The Lubricants sector benefits from benzene's applications in creating high-quality synthetic oils. The shift towards superior performance lubricants that promote engine efficiency and reduce wear continues to enhance the market's reliance on benzene. Although affected by the rise in bio-lubricants, the performance characteristics provided by benzene-derived lubricants maintain their competitive edge, securing a position within the market.

Pesticides

In the Pesticides application, benzene derivatives are utilized in formulating effective agricultural products, helping to enhance agricultural yield and protect crops. The rising global demand for food production and the necessity for effective pest control measures continue to motivate investment in pesticide formulations. As agricultural practices evolve, the necessity for benzene in producing novel, efficient pesticides maintains this sector's relevance in the overall benzene market landscape.

Insights On End User

Packaging

The packaging industry is expected to dominate the Global Benzene Market due to the increasing demand for packaged goods and sustainable packaging solutions. Benzene is a key ingredient in producing plastics, resins, and synthetic fibers essential for various packaging applications. With the rise in e-commerce and food delivery services, the need for efficient and protective packaging is surging. Benzene derivatives such as polystyrene and polyethylene are crucial components in achieving these robust packaging solutions. As consumer preferences shift toward convenience, organizations are investing heavily in packaging innovations that require benzene, solidifying its leading position in the market.

Pharmaceuticals

The pharmaceuticals sector plays a vital role in the benzene market, accounting for a significant portion of benzene’s applications. The industry utilizes benzene for synthesizing various essential drugs and active pharmaceutical ingredients (APIs). As the global population ages and health challenges increase, the demand for pharmaceutical products is rapidly rising. This uptrend in healthcare needs translates into a higher requirement for benzene-related compounds, driving growth within this market. Furthermore, continuous advancements and research in drug formulation will further expand the pharmaceutical industry's reliance on benzene.

Agriculture

In the agriculture sector, benzene is primarily used in the manufacture of pesticides and herbicides. The growing global population and increasing food production needs drive demand in this area. Additionally, concerns regarding food safety and crop efficiency make it crucial for agricultural solutions to leverage advanced chemical formulations, many of which require benzene derivatives. As sustainable agricultural practices evolve, the continued reliance on benzene-based products can influence growth within this sector, albeit at a relatively slower pace compared to packaging.

Constructions

The construction industry represents a notable for benzene due to its applications in construction materials like adhesives, coatings, and sealants. As urbanization and infrastructural development intensify globally, the demand for high-performance materials increases. Benzene-based products enhance material durability, ensuring longevity and resistance to external elements. Despite its importance, this faces competition from emerging alternative materials driving the market dynamics and mitigating some of the growth potential for benzene applications.

Textiles

In the textiles industry, benzene is mainly used in producing synthetic fibers such as polyester and nylon. While the textile sector remains essential for benzene application, its growth is subject to fluctuations due to changing consumer preferences for sustainable and eco-friendly fabrics. Increasing environmental consciousness is pushing the industry toward using biodegradable alternatives, which may impact the demand for benzene derivatives. However, the ongoing development in textile manufacturing processes continues to sustain a baseline demand for benzene, albeit not as pronounced as other areas like packaging.

Global Benzene Market Regional Insights:

Asia Pacific

Asia Pacific is projected to dominate the Global Benzene market due to its robust industrial growth and significant demand for benzene derivatives such as styrene, phenol, and aniline in the region. Countries like China and India are experiencing rapid urbanization and infrastructure development, propelling the demand for plastics, synthetic fibers, and chemicals, all of which rely heavily on benzene as a building block. Furthermore, the presence of major petrochemical manufacturers in the region, combined with competitive pricing and a growing middle class, positions Asia Pacific as a key player in shaping the benzene industry landscape for years to come.

North America

North America is witnessing steady growth in the benzene market, driven primarily by the thriving automotive and chemical sectors. The growing use of benzene in the production of high-octane gasoline and various petrochemicals appeals to the region's established infrastructure and technological advancements. However, while market demand is consistent, it faces challenges such as stringent environmental regulations and a shift toward sustainable alternatives, which may inhibit more aggressive growth compared to Asia Pacific.

Europe

Europe remains an important market for benzene, largely due to stringent regulatory frameworks aimed at reducing emissions and promoting green chemistry. The demand for benzene in specialty chemicals, pharmaceuticals, and automotive applications contributes positively to the market. However, factors such as economic slowdowns, competitive pressure from low-cost producers in Asia, and existing supply chain disruptions may hinder Europe’s ability to compete effectively as a dominant region in the benzene market.

Latin America

Latin America exhibits moderate demand for benzene, driven by growth in the automotive and consumer goods sectors. However, the market grapples with economic volatility, political instability, and limited infrastructure development, which restrict overall growth potential. While emerging economies within the region present some opportunities for investment in benzene production, they currently lack the scale and production capacity needed to compete with more dominant regions like Asia Pacific.

Middle East & Africa

The Middle East & Africa region has seen a growing focus on the petrochemical sector, with several countries investing in expanding their production capabilities. However, the benzene market in this region faces challenges such as geopolitical instability and fluctuating oil prices, which can impact production levels and market growth. While there is potential for development as more investments flow into the region, it currently lags behind Asia Pacific in terms of overall market dominance.

Benzene Competitive Landscape:

Key contributors in the worldwide benzene sector, comprising leading chemical producers and refiners, spearhead advancements and operational efficiency, simultaneously impacting pricing structures and supply mechanisms. Their collaborative approaches and strategic alliances play a pivotal role in molding market trends and influencing demand across diverse fields, including the automotive and pharmaceutical industries.

The benzene market features several key players, including BASF SE, Chevron Phillips Chemical Company LLC, ExxonMobil Chemical Company, INEOS Group Limited, LyondellBasell Industries N.V., Reliance Industries Limited, and SABIC (Saudi Basic Industries Corporation). Other notable participants are Shell Chemical Company, TotalEnergies SE, and China National Petroleum Corporation (CNPC). Additionally, Dow Chemical Company, Mitsubishi Chemical Corporation, Formosa Plastics Corporation, JX Nippon Oil & Energy Corporation, and Bharat Petroleum Corporation Limited significantly impact the market. Moreover, companies like GS Caltex Corporation, Maruzen Petrochemical Co., Ltd., and Zhejiang Petroleum and Chemical Company contribute to the global competitiveness of the benzene supply chain.

Global Benzene COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly impacted the global benzene market, causing a decline in industrial demand and production levels. This disruption resulted in price volatility and complications within supply chains.

The benzene market experienced significant changes due to the COVID-19 pandemic, facing both disruptions and evolving demand patterns. At the outset, lockdown measures and a decline in industrial operations led to a reduction in benzene usage across various sectors, including automotive and construction, which in turn caused prices to fall. Conversely, the ened demand for pharmaceuticals, personal care items, and cleaning products—where benzene is an essential ingredient—painted a different picture. As economies began to reopen, there was a gradual recovery facilitated by an increase in production capacities and a resurgence in consumer spending. However, challenges in supply chains, including transportation limitations and workforce shortages, affected the availability and pricing of benzene. By late 2021 and into 2022, the market began to stabilize with signs of price recovery; nonetheless, the long-term effects of shifting consumer preferences and regulatory changes continue to be vital factors for the future dynamics of the market.

Latest Trends and Innovation in The Global Benzene Market:

- In July 2022, Covestro announced its acquisition of the Dutch company, Resins and Functional Materials (RFM), significantly expanding its portfolio in the specialty chemicals sector, including benzene derivatives.

- In August 2022, LyondellBasell completed the installation of a new benzene extraction unit at its plant in Wesseling, Germany, enhancing its production capacity and efficiency in benzene manufacturing.

- In November 2022, INEOS announced the construction of a new benzene production facility in Antwerp, Belgium, which is expected to begin operations in mid-2024, aiming to cater to increasing demand in the European market.

- In March 2023, Shell launched a pilot project to utilize renewable energy sources for the benzene production process at its facility in Geelong, Australia, as part of its commitment to sustainability and reducing carbon emissions.

- In June 2023, Eastman Chemical Company revealed its strategic partnership with the Belgian company, PAVIS, to jointly develop bio-based benzene production technologies, targeting a more sustainable supply chain.

- In September 2023, Reliance Industries announced an investment of $1 billion to enhance its petrochemical complex in Jamnagar, India, including improvements to its benzene and derivatives production capabilities.

- In October 2023, BASF and SABIC entered into a joint venture to develop advanced chemical recycling technologies for benzene and its derivatives, aiming to improve sustainability in the petrochemical industry.

Benzene Market Growth Factors:

The benzene market is propelled by growing demands from the automotive, chemical, and pharmaceutical sectors, alongside the emergence of specialized uses in advanced materials.

The benzene market is influenced by several key growth drivers, notably the increasing demand for petrochemical products, particularly in the synthesis of styrene, phenol, and cyclohexane. These compounds are vital for a variety of end-use sectors such as plastics, automotive manufacturing, and electronics. Additionally, the surging usage of polycarbonate and polystyrene in both packaging and construction further enhances the need for benzene. The expanding automotive industry, particularly with the rise of electric vehicles, increasingly relies on benzene derivatives for the creation of lightweight components. Furthermore, the trends of urbanization and industrial growth in emerging markets lead to a ened demand for benzene, as substantial amounts of chemical products are required for infrastructure development. Technological advancements in extraction and refining methods also contribute to greater efficiency in benzene production, rendering it more economically feasible. Moreover, government policies and initiatives that advocate for greener manufacturing practices are fostering innovation within the benzene production sector, thus propelling market growth. Environmental issues related to the toxicity of benzene are driving the development of alternative materials and recycling efforts, presenting potential challenges. Nonetheless, the primary demand factors, combined with the expanding markets in developing economies and ongoing technological advancements, suggest a favorable long-term perspective for the benzene market.

Benzene Market Restaining Factors:

The advancement of the benzene market is notably impeded by strict regulatory measures and health-related issues associated with benzene exposure.

The benzene market faces various constraints that influence its development and operational dynamics. Foremost among these are stringent environmental regulations designed to mitigate air and water pollution, which place considerable limitations on both the production and application of benzene. Recognized as a hazardous substance with associated health risks, including its carcinogenic properties, benzene's use is heavily scrutinized. Additionally, the inherent price volatility of benzene—largely driven by changes in crude oil prices and the availability of feedstocks—can discourage investment and stable output.

Competing alternatives, such as toluene and xylene, pose further challenges to benzene’s market position, as companies increasingly opt for safer and more sustainable materials. The shift towards sustainability and green chemistry also catalyzes the exploration of bio-based chemicals, thereby diminishing reliance on traditional petrochemicals like benzene.

Nonetheless, there are promising developments on the horizon. Innovations in technology, particularly in cleaner production methods and prospects for growth in new sectors such as lithium-ion batteries and specialty chemicals, offer an optimistic viewpoint for the benzene market. By concentrating on innovative and sustainable approaches, stakeholders have the potential to navigate these challenges successfully and seize new avenues for expansion.

Key Segments of the Benzene Market

By Derivative

- Ethylbenzene

- Cumene

- Alkylbenzene

- Cyclohexane

- Nitrobenzene

- Others

By Manufacturing Process

- Catalytic Reforming

- Toluene Disproportionation

- Toluene Hydrodealkylation

- Pyrolysis

- Steam Cracking of Naphtha

- From Biomass

By Application

- Plastics

- Solvent

- Chemical Intermediates

- Surfactants

- Rubber Manufacturing

- Detergents

- Explosives

- Lubricants

- Pesticides

- Others

By End User

- Packaging

- Pharmaceuticals

- Agriculture

- Constructions

- Textiles

- Others

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America