Market Analysis and Insights

With a predicted CAGR of 4.13% from 2021 to 2030, the global catalyst market was valued at USD 35.7 billion in 2020 and is expected to expand to USD 57.9 billion by 2030.

The government's transition to renewable energy sources as a result of growing carbon emissions and the resulting climate change has prompted firms to switch to alternative fuels, and this shift is being sparked by an increase in government activities in this direction. The need for catalysts is anticipated to increase in the near future as alternative energy and fuels like biodiesel and shale gas fuel gain popularity.

Catalyst Market Scope :

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2030 |

| Study Period | 2018-2030 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2030 | USD 57.9 billion |

| Growth Rate | CAGR of 4.13% during 2021-2030 |

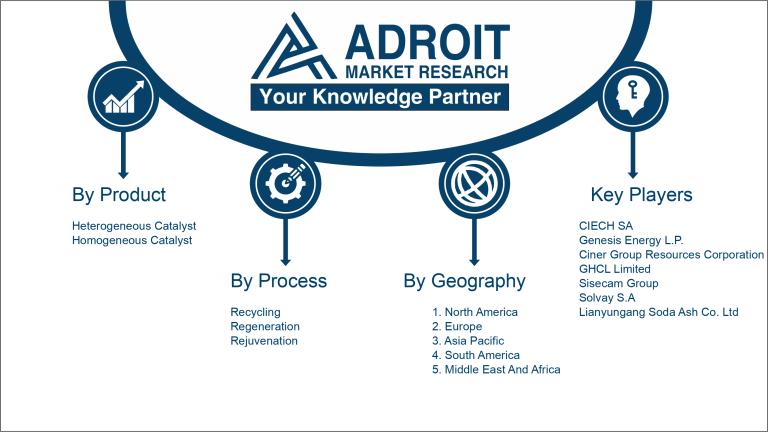

| Segment Covered | by Product,by Process,by Raw Material, by Application by Region . |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | CIECH SA, Genesis Energy L.P., Ciner Group Resources Corporation, GHCL Limited, Sisecam Group, Solvay S.A, Lianyungang Soda Ash Co. Ltd, NIRMA LIMITED, Shandong Haihua Group Co. Ltd, FMC Corporation, Tata Chemicals Limited, Novacap Group, Tronox limited, SEQENS Group, DCW Limited, OCI COMPANY Ltd., IMARC Group, |

Market Definition

By changing the activation energy of the process, chemical compounds known as catalysts are utilised to accelerate chemical processes. Used catalysts, however, can be put to use once they have been cleaned up as they are not consumed during the process.

Zeolites, metals, compounds, enzymes, and organometallic materials are only a few of the diverse types of catalysts that are easily available on the market. Zeolites are an aluminosilicate family of porous, wet materials that can be synthesized chemically or naturally. They are economically most advantageous due to their unique crystal structure, which enables them to serve as molecular sieves.

In recent years, heterogeneous metal catalysts have been the focus of catalyst research because they have the potential to reduce side reactions while increasing product yields by overcoming the limitations of their homogeneous counterparts. The primary market growth catalysts are those. As a result, platinum has been replaced with graphene doped with nitrogen and enhanced with cobalt atoms, which represents a big step towards more affordable catalysts for the production of energy.

Key Market Segmentation

Insights on Product

The Heterogeneous Segment is Valued for the Highest Share

The heterogeneous catalyst segment accounted for around 73.03% of the market share in 2022 and led the catalyst market based on product. The heterogeneous catalysts are created by converting the homogeneous catalysts into them through solid supports, which lessens their toxicity. Heterogeneous catalysts include, among others, sulfonated silica, sulfated zirconia, sulfonated MOFs, and sulfonated carbon compounds.

Heterogeneous catalysts provide a number of advantages over homogeneous catalysts, including the ability to separate catalysts easily, simplicity in use, and affordability. These advantages have helped this market sector develop rapidly. Additionally, it is anticipated that throughout the projection period, the segment's growth would pick up speed due to the growing popularity of heterogeneous catalysts in the manufacture of biodiesel.

During the time of forecasting, the homogeneous catalyst segment is anticipated to expand at a rapid pace. The most popular kinds of homogeneous catalysts include sulfuric acid, phosphoric acid, boric acid, and hydrochloric acid. Comparing homogeneous catalysts to their heterogeneous counterparts, it is known that the former performs better in industrial and raw material processes. Toxic pollutants are nevertheless released during the homogenization process, potentially endangering the environment. Therefore, there is a growing need for an eco-friendly substitute, and the emergence of an eco-friendly and biodegradable homogeneous catalyst like methanesulfonic acid has helped to meet this need.

Insights on Application

The Chemical Synthesis Segment Valued for the Highest Share

Depending on the application, the chemical synthesis segment held a market share of around 27% and was the market leader for catalysts in the world in 2022. It includes the chemistry of raw materials as well as those utilized in processes as Contact, Haber, and the conversion of ammonia to nitric acid, which use catalysts. Therefore, the development of the chemical industry and the market for chemical synthesis are strongly intertwined. Chemical synthesis applications have been aided by its exceptional qualities, such as the encouragement of enantioselective methods.

Insights on Region

The ASAP Region Accounted for the Highest Share

In 2022, the Asia Pacific region had a commanding 34.9% market share and dominated the worldwide catalyst market. Chemicals, petrochemicals, and the automotive sectors are what majorly drive the Asia Pacific catalyst industry. China has a sizable number of polymer and chemical manufacturing firms, which has a substantial positive impact on the expansion of the Asia Pacific catalyst market. Due to its cheap production costs and growing local demand, China has been a popular destination for petrochemical and chemical product manufacture. The expansion of the Asia Pacific catalyst market has been greatly assisted by supportive government policies regarding FDIs and industrialization.

Key Company Profiles

The market participants' increasing investments will provide new possibilities in the global catalyst industry. The principal players include CIECH SA, Genesis Energy L.P., Ciner Group Resources Corporation, GHCL Limited, Sisecam Group, Solvay S.A, Lianyungang Soda Ash Co. Ltd, NIRMA LIMITED, Shandong Haihua Group Co. Ltd, FMC Corporation, Tata Chemicals Limited, Novacap Group, Tronox limited, SEQENS Group, DCW Limited, OCI COMPANY Ltd., IMARC Group, and Other Key Players.

COVID-19 Impact and Market Status

Global supply chains, particularly those for catalyst materials and components, were interrupted by the epidemic. Catalyst manufacturing and transportation were impacted by lockdowns, traffic restrictions, and plant closures.

Due to the pandemic, several businesses, including the automobile and aviation sectors, had a considerable drop in demand. This resulted in a decrease in the use of catalysts in industries like jet engines and automobile catalytic converters. The need for specific catalysts increased in several industries, such as chemicals and pharmaceuticals.

In the manufacture of medicines and personal protective equipment (PPE), for instance, catalysts are essential. Price instability in the catalyst market may be induced by the pandemic's mismatches in supply and demand. Prices for several catalyst materials changed as a result of supply chain interruptions.

As laboratories and research facilities faced constraints, which hampered the development of novel catalyst technologies, research and development efforts in the catalyst industry may have been impacted. Businesses in the catalyst sector encountered difficulties keeping up with employee shifts to remote work and sustaining communication. This could have had an impact on creativity and productivity.

Latest Trends

1. Environmentally friendly and sustainable catalysts are becoming more and more important. This comprises catalysts made to employ renewable or eco-friendly materials, cut down on energy use, and minimize the production of dangerous byproducts.

2. The increased surface area of nanostructured catalysts, which boosts catalytic activity, has attracted attention. Fuel cell, chemicals, and environmental applications are just a few of the businesses looking into using these catalysts.

3. The manufacturing of medicines and biofuels has seen a rise in the use of enzyme catalysts, sometimes referred to as biocatalysts. There is less need for harsh chemicals because they have excellent selectivity and frequently function in benign settings.

4. The chemical, petrochemical, and automotive sectors' catalytic processes have been enhanced as a result of developments in heterogeneous catalysts, which reside in a distinct phase from the reactants. These catalysts make recycling and separation easier.

5. Continuous flow processes are increasingly employing catalysts. With this strategy, response parameters may be precisely controlled, which can improve safety and effectiveness.

Significant Growth Factors

Globally stricter environmental rules, particularly in sectors like automotive (catalytic converters) and petrochemicals (emission control), are driving up demand for catalysts.

The petrochemical sector has expanded, particularly in developing nations. For the manufacturing of petrochemicals, processes including polymerization, reforming, and cracking depend on catalysts.

Catalysts are essential in hydrogen generation, fuel cells, and renewable energy technologies, driving market development as the globe transitions to sustainable energy sources. The creation of eco-friendly catalysts and catalytic processes that save energy and waste is motivated by the quest for sustainability.

The catalyst market is expanding as a result of rising demand for chemicals across several industries, including medicines, agriculture, and consumer products. The development of more effective and adaptable catalysts as a result of ongoing research and development is broadening the range of uses for these materials.

Restraining Factors

The high cost of catalysts, particularly in price-sensitive markets, may prevent some sectors from using modern catalyst technology.

It can be difficult to produce catalysts without the necessary raw ingredients, including rare earth elements. Market effects may result from supply interruptions. New catalyst development and commercialization can be technically difficult and time-consuming, which might hinder market expansion. Recessions and economic downturns may result in a decline in industrial activity and a consequent drop in the demand for catalysts.

Certain catalysts involve poisonous or ecologically hazardous elements, which may result in regulatory limits or negative public perception. With several reputable companies, the catalyst industry is quite competitive. Gaining market share may be difficult for new competitors. Prices and availability of catalysts can be impacted by trade disputes and geopolitical concerns that affect the global supply chain.

Catalysts can deactivate over time for a variety of reasons, necessitating regeneration or replacement, which can raise operating expenses. Although catalysts are necessary for processes that use a lot of energy, some applications may require less of them overall as a result of increased energy efficiency.

Recent Developments in the Global Catalyst Market: A Snapshot

• Johnson Matthey (JM) and Hystar collaborated on a three-year strategic supply deal in May 2023 to support the production of renewable hydrogen, which uses catalysts in membrane electrode assemblies to power the electrolysis process and generate renewable hydrogen.

• A revolutionary catalyst invention, the X3DTM technology, which leverages the potential of 3D printing in production, was announced by BASF SE in September 2022. This state-of-the-art method makes it possible to create open-structure catalysts, which significantly lower the pressure drop inside the reactor and achieve a remarkable surface area for improved performance.

• The P/PR 200 Series, Axens' most recent addition to the renowned Symphony Catalyst family, was announced in November 2021. Through a rigorous pilot testing programme, this revolutionary series demonstrates higher activity, stability, and superior product selectivity compared to its predecessor, producing amazing unit economics and allowing additional operational flexibility for the valued partners.

Key Segments Catalyst Market

by Product

• Heterogeneous Catalyst

• Homogeneous Catalyst

by Process Overview

• Recycling

• Regeneration

• Rejuvenation

by Raw Material Overview

• Chemical Compounds

• Zeolites,

• Metals,

• Organic Material,

• Enzymes,

by Application Overview

• Heterogeneous Catalyst,

• Homogeneous Catalyst

Regional Overview

North America

• U.S

• Canada

Europe

• Germany

• France

• UK

• Rest of Europe

Asia Pacific

• China

• India

• Japan

• Rest of Asia Pacific

South America

• Mexico

• Brazil

• Rest of South America