Chemical Milling Market Analysis and Insights:

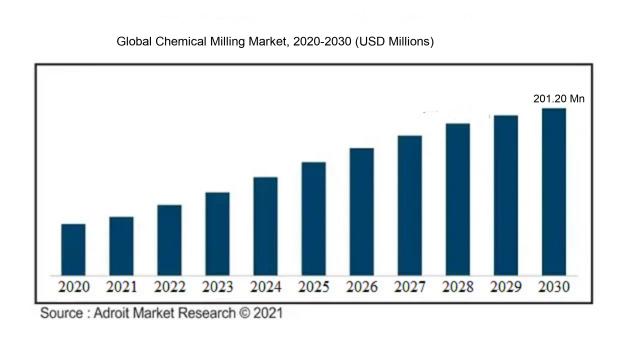

From 2024 to 2030, the global chemical milling market is expected to increase at a compound annual growth rate (CAGR) of 3.69%, reaching an estimated USD 201.20 million in value. The market was worth USD 150.26 million in 2024.

The growth and evolution of the chemical milling market are shaped by a plethora of influential factors. One of the key drivers is the increasing demand for lightweight components within the aerospace and defense industry, driven by a focus on fuel efficiency. For the production of accurate and lightweight parts utilized in defense and aeronautical applications, chemical milling is essential. Furthermore, the expanding electronics sector, fueled by the need for sophisticated electronic devices, necessitates precise and intricate milling processes. Chemical milling facilitates the production of intricate electronic components like printed circuit boards with high precision and efficiency. The need for chemical milling services is also rising as a result of the car industry's rise, which is being fueled by urbanization and rising disposable income. This industry uses chemical grinding to produce lightweight parts that lower pollutants and improve fuel economy. Additionally, advancements in chemical milling processes, such as the development of environmentally friendly chemicals and innovative milling techniques, are gaining traction in the market. These developments provide economical and environmentally friendly solutions, which further fuel the market expansion for chemical milling.

Chemical Milling Market Definition

Chemical machining, commonly known as chemical etching, is an advanced manufacturing process that uses chemical processes to remove material from a metal surface selectively. This method enables precise and controlled manipulation or reduction of the material, making it a preferred choice in sectors like aerospace and electronics for crafting delicate and lightweight parts.

The ability of chemical etching to precisely remove metal from components makes it an essential technique in a variety of sectors, including electronics, automotive, and aerospace. This process is crucial for ensuring accurate dimensional control and creating intricate metal shapes and patterns that would be challenging to achieve using conventional machining techniques. Particularly beneficial in crafting lightweight structures, chemical milling facilitates the elimination of superfluous material without sacrificing strength or utility. Furthermore, it facilitates the manufacturing of elaborate designs, diminishing the requirement for numerous parts and assembly procedures. In conclusion, chemical milling significantly contributes to improving manufacturing efficiency, supporting cost-effective production, and fostering novel design opportunities.

Chemical Milling Market Segmental Analysis:

Insights On Type

Titanium Alloys

The worldwide market for chemical milling is anticipated to be dominated by titanium alloys. The remarkable qualities of titanium alloys, such as their high strength-to-weight ratio, resistance to corrosion, and superior heat resistance, are responsible for their great demand. These alloys are widely used in a variety of industries, such as the automotive, medical, and aerospace sectors. Because of their durability and light weight, titanium alloys are widely used in the aerospace sector, particularly for airplane components. Furthermore, titanium alloys are used in the medical field for surgical equipment and implants. Titanium alloys' dominance in the global chemical milling market is a result of these reasons.

Steel Alloys

The global chemical milling market includes steel alloys as a major segment. Steel alloys are utilized extensively in the manufacturing, automotive, and construction industries because of their affordability, strength, and durability. Chemical milling techniques are utilized extensively for shaping and patterning steel alloy components. The need for steel alloys in the automotive and construction sectors, particularly in emerging nations, is anticipated to propel this segment's expansion in the chemical milling market.

Copper Alloys

Copper alloys are an important part of the global chemical milling market, even if they are not the leading industry. Since copper alloys have exceptional electrical and thermal conductivity, they are essential in a variety of industries, including plumbing, electronics, and telecommunications. While their usage in chemical milling may be relatively lower compared to titanium and steel alloys, the demand for copper alloys remains significant due to their unique properties and wide range of applications.

Aluminum Alloys

Aluminum alloys are another important sector in the Global Chemical Milling Market. Alloys made of aluminum have good conductivity qualities, a high strength-to-weight ratio, and resistance to corrosion. These alloys are widely used in the aerospace sector, where it is essential to reduce weight. Aluminum alloys are also often utilized in consumer electronics, packaging materials, and vehicle components. The demand for aluminum alloys in chemical milling is driven by their versatility and the need for lightweight, yet durable, components.

Others

The Others category includes a variety of alloys that do not fit within the above-mentioned basic groups. It includes niche alloys specifically designed for certain applications. Although the contribution of "Others" may be relatively small compared to the dominating part, they still have a role to play in the Global Chemical Milling Market. These specialty alloys meet particular needs in sectors including electronics, marine, and defense. Despite their smaller market share, the demand for these specialized alloys ensures their relevance in the chemical milling industry.

Insights On Application

Aerospace

The aerospace application is expected to dominate the Global Chemical Milling Market due to its increasing demand for aircraft components. Chemical milling is widely used in the aerospace industry to shape and modify metal components, especially those made of titanium and aluminum alloys. With the continuous growth of the global aerospace industry, driven by an increase in air passenger traffic and defense spending, the demand for chemical milling in this part is expected to remain high. Aerospace companies are constantly seeking lightweight and durable components, and chemical milling offers precise and efficient methods for achieving these requirements.

Electronic

It is anticipated that the demand for the electronic application of the global chemical milling market would increase significantly. The production of electronic components, including printed circuit boards (PCBs), semiconductor chips, and connections, depends heavily on chemical milling. Rapid technological breakthroughs and the growing use of electronic devices in a variety of sectors are driving up demand for intricate and accurate electronic components. Chemical milling enables the production of intricate patterns and features on electronic components, ensuring high performance and reliability.

Medical

The medical application of the Global Chemical Milling Market is likely to experience a steady growth rate. Chemical milling is extensively used in the medical industry for manufacturing components used in medical devices, implants, and surgical instruments. An aging population, an increase in the frequency of chronic illnesses, and improvements in healthcare facilities are driving demand for implants and medical devices. Chemical milling provides the flexibility to create complex shapes and profiles in medical components, ensuring precise functionality and compatibility with human anatomy.

Automotive

The automotive application of the Global Chemical Milling Market is expected to witness steady demand. Chemical milling is used in the automotive industry for manufacturing various components, including engine parts, transmission components, and chassis parts. Chemical milling provides advantages such weight reduction, increased fuel economy, and higher performance in response to the growing need for lightweight automobiles and cutting-edge engine technology. However, the dominance of the automotive part may be overshadowed by the stronger growth expected in the aerospace and electronic parts.

Others

The Others category of the Global Chemical Milling Market includes applications in various industries not covered by the specific parts mentioned above. This part may include consumer goods, packaging, energy, and other sectors that utilize chemical milling for specific component fabrication purposes. While the dominance of this part cannot be accurately predicted without further analysis, it is expected to have a smaller market share compared to the aerospace, electronic, medical, and automotive parts. The demand in the "Others" category will depend on specific industry trends and requirements.

Global Chemical Milling Market Regional Insights:

Europe

Europe is anticipated to lead the world market for chemical milling. There are several reasons for this. To begin with, Europe is home to several reputable chemical milling businesses that have been doing business there for a long time. These businesses have created cutting-edge chemical milling technologies and procedures and have a significant market share. A strong aerospace and defense sector is another important end-user for chemical milling in Europe. The robust automotive sector in the area contributes to the increased need for chemical milling services. Overall, Europe's mature market, technological advancements, and presence of key industries make it the dominating region in the global chemical milling market.

North America

In the worldwide market for chemical milling, North America is a significant area. The aerospace and defense sectors are well-represented in the area and are big users of chemical milling services. The aerospace sector, in particular, requires precision machining and surface finishing for its components, making chemical milling services highly in demand. Additionally, North America is home to several leading chemical milling companies, which contribute to the region's dominance in the market. Additionally, the area has a robust infrastructure for research and development, which facilitates ongoing technical developments in the chemical milling industry.

Asia Pacific

The chemical milling market is expanding significantly in Asia Pacific. This is due to a number of causes. First, the manufacturing sector is flourishing in the area, especially in South Korea, Japan, and China. Chemical milling services are in high demand due to the sizeable customer base in these nations. In addition, nations such as China and India are making significant investments in their aircraft industries, making Asia Pacific a key aerospace center. This further boosts the demand for chemical milling services in the region. Additionally, the rapid urbanization and industrialization in Asia Pacific contribute to the growth of the chemical milling market.

Latin America

Latin America accounts for a smaller share in the global chemical milling market but is gradually gaining traction. The region is witnessing growth in industries such as aerospace, automotive, and electronics, which are driving the demand for chemical milling services. Furthermore, the region's favorable government initiatives to attract foreign investments and promote industrial growth are propelling the market. However, the market growth in Latin America is still relatively moderate compared to other regions, primarily due to the presence of more established markets elsewhere. Nonetheless, the increasing industrial activities and favorable business environment in Latin America indicate potential growth opportunities in the chemical milling market.

Middle East & Africa

The Middle East & Africa region has a smaller presence in the global chemical milling market. The market is primarily driven by the aerospace and defense industries in countries like Saudi Arabia and the United Arab Emirates. These countries have been investing heavily in their defense sectors, leading to the increased demand for chemical milling services. However, the market growth in the region is relatively limited, mainly due to the absence of a well-established industrial base in most countries. While there is a potential for growth in the future, it is anticipated that the Middle East & Africa region will remain a relatively smaller player in the global chemical milling market.

Global Chemical Milling Market Competitive Landscape:

Prominent figures within the worldwide Chemical Milling industry hold a significant position in the production of chemicals utilizing chemical etching methodologies to achieve exact and meticulous outcomes. Their involvement fosters progress and creativity across various sectors including aerospace, electronics, and automotive industries.

Prominent companies in the Chemical Milling Market comprise Precision Micro, Tech-Etch, United Western Enterprises, Orbel Corporation, Wist Europe, Great Lakes Engineering, Lancaster Metals Science Co., Tucana Engineering Ltd., VACCO Industries, and Advanced Chemical Etching Limited. These firms are strongly engaged in the chemical milling domain, delivering state-of-the-art solutions and services across sectors like aerospace, electronics, automotive, medical, and defense. Through their knowledge and technological progress, these leading organizations contribute substantially to the development of the chemical milling sector while addressing the varied requirements of their clientele.

Global Chemical Milling Market COVID-19 Impact and Market Status:

Due to the Covid-19 epidemic, the worldwide chemical milling industry has been significantly disrupted, resulting in decreased output and demand, supply chain disruptions, and uncertain development prospects.

The chemical milling market has been significantly impacted by the COVID-19 pandemic, with global supply chains facing disruptions due to government-imposed restrictions to curb the virus's spread. This has led to a reduction in demand for chemical milling services, as various industries have seen economic downturns and decreased production levels. The closure of manufacturing facilities and limitations on international trade have added to the market's challenges. Despite these obstacles, there have been positive developments such as an increased focus on hygiene and safety measures, leading to a higher demand for chemical milling services in the healthcare sector, specifically for medical device manufacturing. As economies recover and manufacturing activities resume, the chemical milling market is expected to bounce back, supported by the growing need for advanced manufacturing processes.

Recent Trends & Innovations in the Chemical Milling Market:

- On June 30, 2020, Lockheed Martin Corporation announced the acquisition of Aerojet Rocketdyne Holdings, Inc., a company that specializes in aerospace and defense technologies.

- In August 2020, BASF SE introduced a new wax emulsion product called "Joncryl® WaxPro" for improving surface properties in various industries, including chemical milling.

- On January 28, 2021, Precision Castparts Corp., a subsidiary of Berkshire Hathaway, completed the acquisition of Permaswage SAS, a leading provider of fluid fittings and connections for the aerospace industry.

- In February 2021, Huntsman Corporation announced the development of a new technology called "ARALDITE® 2050" for adhesive bonding, which offers improved performance in chemical milling applications.

- On March 15, 2021, E. I. du Pont de Nemours and Company (DuPont) acquired Laird Performance Materials, a manufacturer of electromagnetic shielding and thermal management solutions, expanding their product portfolio in the chemical milling market.

- In April 2021, Henkel Corporation introduced a new product called "Bonderite® M-NT 8453" for metal pre-treatment processes, which can be utilized in chemical milling operations.

Chemical Milling Market Growth Factors:

The chemical etching industry is poised for substantial expansion as a result of increasing market requirements for precise components across sectors such as aerospace, automotive, and electronics.

The chemical milling industry is poised for substantial growth in the upcoming years due to various influential factors. The increasing need for lightweight materials in sectors like aerospace, automotive, and electronics is propelling market expansion. Chemical milling emerges as a viable solution for reducing component weight while maintaining strength, making it a favorable choice for these industries. Moreover, the trend towards precision engineering and component miniaturization is fueling the demand for chemical milling techniques. Technological advancements have positioned chemical milling as a crucial method for achieving precise and intricate designs, leading to widespread adoption across diverse sectors. Additionally, the industry's focus on sustainable manufacturing and adherence to environmental regulations has spurred the development of eco-friendly chemical milling processes, further accelerating market growth as businesses aim to reduce environmental impact. Furthermore, the growth of the electronics industry, particularly the semiconductor, is anticipated to boost the need for chemical milling due to the precise milling processes involved in producing electronic components with specific specifications and functionalities. Collectively, these factors are shaping the chemical milling landscape and paving the way for future growth opportunities.

Chemical Milling Market Restraining Factors:

An important obstacle encountered by the chemical milling industry pertains to the rigorous environmental standards and issues concerning the utilization of chemicals within the procedure.

The chemical milling industry encounters various obstacles that impede its progress and advancement. Firstly, strict regulations governing the disposal and management of chemical waste present a significant challenge to the market. Adherence to specific environmental guidelines necessitates increased compliance costs for companies involved in chemical milling processes. Secondly, the substantial initial investment needed for the establishment of chemical milling facilities serves as a notable barrier to entry for new players in the sector. The intricate and costly machinery requirements, coupled with the demand for skilled personnel, contribute to the overall financial outlay. Moreover, the market contends with hurdles stemming from the availability of alternative manufacturing methodologies. Technological progressions in areas like 3D printing and laser cutting offer substitute avenues for precision machining, thereby diminishing the demand for chemical milling services. Fluctuations in the prices of raw materials also pose a challenge to the profitability of chemical milling enterprises, given their heavy reliance on inputs such as acids, etchants, and masking materials. Notwithstanding these impediments, the chemical milling sector can capitalize on growth opportunities by prioritizing sustainable practices and embracing innovative methodologies. Investing in research and development to create environmentally friendly chemicals and processes can align businesses with the escalating preference for eco-conscious manufacturing approaches. Furthermore, the differentiation of chemical milling companies in the market and the mitigation of restraining factors can be achieved through effective marketing, superior customer service, and the provision of tailored solutions.

Key Segments of the Chemical Milling Market

Type Overview

• Steel Alloys

• Copper Alloys

• Titanium Alloys

• Aluminum Alloys

• Others

Application Overview

• Aerospace

• Electronic

• Medical

• Automotive

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America