Clean-in-Place Market Analysis and Insights:

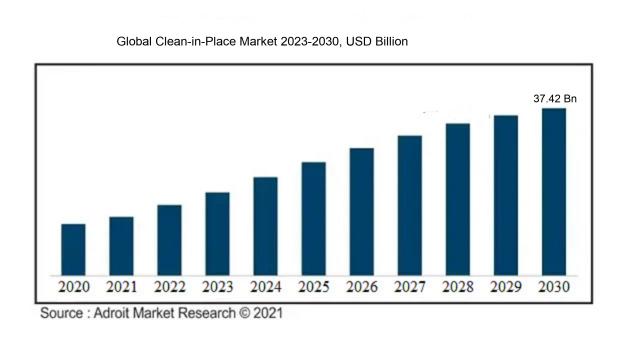

It is projected that the Clean-in-Place (CIP) market would reach a value of USD 37.42 billion in 2030, having grown from 2024 to 2023 at a compound annual growth rate (CAGR) of 15.39%.

A number of major reasons are driving the Clean-in-Place (CIP) systems market's growth. The primary factor driving the need for CIP solutions is the emphasis on cleanliness and compliance with food safety laws across a variety of industries, most notably the food and beverage sector. Concerns regarding product contamination and the necessity to uphold high-quality standards have prompted the adoption of CIP methodologies for comprehensive cleaning of processing equipment. Moreover, the increasing drive for automation and enhanced efficiency in industrial processes is a key driver fueling the expansion of the CIP market. CIP systems make automated cleaning procedures possible, which guarantee reliable and effective cleaning results in addition to saving time and lowering manual work. The market is also expanding because to the growing use of CIP technologies in the biotechnology and pharmaceutical industries, where sterile environment maintenance is crucial. Lastly, the ened awareness among manufacturers about the cost-saving advantages of CIP systems, particularly in terms of water and energy conservation, is also contributing to market expansion. In essence, the growth of the Clean-in-Place market is underpinned by the imperatives of regulatory compliance, operational enhancement, cleanliness maintenance, and cost reduction across various industries.

Clean-in-Place Market Definition

The Clean-in-Place (CIP) technique is widely employed in various industries like food and beverage and pharmaceuticals to clean equipment effectively without requiring disassembly. This method utilizes specific cleaning solutions and procedures to eliminate impurities and uphold cleanliness standards.

The process known as Clean-in-Place (CIP) is a critical procedure utilized across a variety of sectors such as the food and beverage, pharmaceutical, and dairy industries. This method involves the thorough cleaning and sanitization of equipment and pipelines without the need for disassembly, resulting in time-saving benefits and promoting enhanced operational efficiency. Notably, CIP is indispensable for upholding product quality standards, eradicating contaminants, and averting cross-contamination risks, which could pose significant health hazards and jeopardize product quality. Furthermore, the implementation of CIP aids in prolonging the lifespan of equipment by eliminating residue build-up, thereby reducing the likelihood of equipment malfunctions and minimizing maintenance-related downtime. Ultimately, CIP serves as a pivotal mechanism in guaranteeing hygienic, secure, and effective operations within industries that prioritize cleanliness and sanitation.

Clean-in-Place Market Segmental Analysis:

-market.jpg)

Insights On Offering

Multi-Tank Systems

Multi-Tank Systems are expected to dominate the Global Clean-in-Place Market. This is due to their ability to provide a higher level of flexibility and efficiency in the cleaning process. Multi-Tank Systems consist of multiple tanks that can be customized to accommodate different cleaning solutions and processes. The versatility of Multi-Tank Systems allows for simultaneous cleaning of multiple parts of a production system, eliminating the need for separate cleaning cycles. This results in reduced downtime and increased productivity. Furthermore, Multi-Tank Systems offer better control over the cleaning parameters, ensuring effective and consistent results.

Single-Tank Systems

The Single-Tank Systems part may have a significant market share but is expected to have less dominance compared to Multi-Tank Systems. Single-Tank Systems offer a simpler and more cost-effective solution for CIP applications, but they may lack the flexibility and efficiency provided by Multi-Tank Systems.

Two-Tank Systems

The Two-Tank Systems offering is also likely to have a smaller market share compared to Multi-Tank Systems. Two-Tank Systems provide the advantage of having separate tanks for cleaning and rinsing, which can enhance the cleaning process. However, the added complexity and cost associated with the additional tank may limit its dominance in the market.

Insights On System Type

Reuse CIP Systems

Reuse CIP Systems are expected to dominate the Global Clean-in-Place Market. The purpose of these systems is to sterilize and clean pipes and equipment used repeatedly in a variety of industries. Among their benefits include lower usage of chemicals and water, more productivity, and enhanced sustainability. With a focus on cost-effectiveness and environmental consciousness, many industries are adopting reuse CIP systems for their cleaning needs. The market is fueled by the growing need for effective cleaning procedures, strict safety and hygienic laws, and the expanding use of automation in production. Reuse CIP systems are therefore anticipated to maintain their dominance in the worldwide clean-in-place industry.

Single-Use CIP Systems

Single-Use CIP Systems, on the other hand, are also an important sector of the clean-in-place market. These systems are designed for one-time use and are particularly suitable for industries that require frequent product changeovers or have specific cleaning requirements. Single-use CIP systems offer benefits such as reduced cross-contamination risk and increased flexibility. However, they are likely to have a smaller market share compared to reuse CIP systems. This is primarily because reuse CIP systems offer long-term operational cost savings and sustainability advantages.

Insights On End-user

Dairy Industry

The Dairy Industry is expected to dominate the Global Clean-in-Place Market. The dairy industry is a major user of clean-in-place systems due to the strict hygiene standards required for milk and dairy product processing. The industry relies heavily on clean-in-place technology to ensure proper cleaning of dairy processing equipment and prevention of bacterial contamination. In the worldwide clean-in-place market, the dairy industry is anticipated to have a leading position due to the growing demand for dairy products and the requirement for effective and sanitary cleaning procedures.

Food Industry

The global clean-in-place market is also dominated by the food industry. As food processing involves various equipment and surfaces that require regular cleaning to maintain hygiene and food safety standards, the demand for clean-in-place systems is expected to be high in this industry. Clean-in-place technology helps in reducing downtime, improving efficiency, and ensuring product quality by providing automated and effective cleaning solutions. With the growing global food industry and the emphasis on food safety regulations, the demand for clean-in-place systems in the food industry is anticipated to be substantial.

Pharmaceuticals Industry

The Pharmaceuticals Industry is yet another sector that holds significant potential in the Global Clean-in-Place Market. In the pharmaceuticals industry, utmost cleanliness and sterility are critical to meet stringent regulatory requirements. Clean-in-place systems play a vital role in maintaining clean and contaminant-free manufacturing environments for drug production and processing equipment. With the increasing demand for pharmaceuticals and the need for stringent cleaning processes, the pharmaceuticals industry is expected to be a prominent user of clean-in-place systems.

Brewery and Beverages Industry

The Brewery and Beverages Industry is another sector that contributes to the Global Clean-in-Place Market. In this industry, clean-in-place systems are used to clean and sanitize brewing equipment and pipelines to ensure product quality and consistency. As the brewery and beverages industry experiences continued growth and innovation in product offerings, the demand for clean-in-place systems is anticipated to increase.

Others

The Others category represents diverse industries that may require clean-in-place systems but do not fall under the dominion of the other mentioned parts. These industries could include sectors such as cosmetics, personal care, water treatment, and others. The contribution of this part to the Global Clean-in-Place Market may vary depending on the specific requirements of each industry and the level of cleanliness and hygiene standards they need to maintain. Further research is needed to determine the exact dominance of this particular part.

Global Clean-in-Place Market Regional Insights:

Asia Pacific

Asia Pacific is expected to dominate the global Clean-in-Place (CIP) market. There are prominent companies in the food and beverage, dairy, and pharmaceutical industries in the area, which has seen tremendous industrial expansion. The need for CIP systems is being driven by the region's increasing urbanization, rising living standards, and shifting customer preferences for packaged and processed foods. Additionally, the CIP market in Asia Pacific is expanding due to greater awareness of food safety and hygiene regulations, as well as increased expenditures in infrastructure development.

North America

North America is one of the prominent markets for Clean-in-Place systems, especially in the food and beverage industry. The region's high degree of automation in manufacturing processes and strict laws pertaining to food safety and cleanliness are what fuel demand for CIP systems. Furthermore, the existence of significant competitors and the ongoing emphasis on R&D initiatives support the expansion of the CIP market in North America.

Europe

Europe is another significant region in the global Clean-in-Place market. Strict laws and standards for food safety and cleanliness are emphasized in the region's food and beverage business, especially in nations like Germany, France, and the United Kingdom. Because of this, CIP systems are required to guarantee appropriate cleaning and sanitation. Furthermore, Europe's biotechnology and pharmaceutical sectors fuel demand for CIP systems, which in turn fuels regional market expansion.

Latin America

The Clean-in-Place market in Latin America is growing steadily due to increasing awareness about food safety, hygiene, and quality standards in the food and beverage industry. The need for CIP systems is being driven by the notable industrial expansion and investments in the food and beverage industry in nations like Brazil, Mexico, and Argentina. Furthermore, the expanding pharmaceutical and dairy industries in Latin America also contribute to the market growth of CIP systems in the region.

Middle East & Africa

The Middle East & Africa region is experiencing gradual growth in the Clean-in-Place market. The region's improving economic conditions, population growth, and increasing focus on food safety and hygiene drive the demand for CIP systems. Countries like United Arab Emirates, Saudi Arabia, and South Africa are witnessing rapid industrialization and urbanization, particularly in the food and beverage sector, which creates opportunities for the CIP market in the region. However, the market is still emerging and has significant growth potential in the coming years.

Global Clean-in-Place Market Competitive Landscape:

Prominent figures within the worldwide Clean-in-Place sector are instrumental in the innovation and production of cutting-edge CIP systems and remedies tailored to meet the cleaning requirements of diverse industries. Additionally, they are pivotal in providing technical assistance, installation services, and training initiatives aimed at ensuring the successful and optimal integration of CIP procedures.

Prominent companies in the Clean-in-Place (CIP) sector comprise an array of renowned entities such as Ecolab Inc., Sani-Matic Inc., Tetra Pak International S.A., GEA Group Aktiengesellschaft, Alfa Laval AB, SPX FLOW Inc., Krones AG, KHS GmbH, Melegari Manghi, and Azbil Corporation. These industry leaders are distinguished in the CIP market for their wide-ranging product portfolios, innovative technological progressions, robust distribution channels, and considerable market foothold. Notably, Ecolab Inc. specializes in cutting-edge solutions in hygiene, water, and energy realms, whereas Sani-Matic Inc. stands out for its tailor-made CIP offerings. Tetra Pak International S.A. is a preeminent provider of solutions for food processing and packaging, while GEA Group Aktiengesellschaft caters to the needs of the food and beverage sectors through its equipment offerings. Alfa Laval AB excels in heat transfer, separation, and fluid management technologies, and SPX FLOW Inc. is distinguished for its comprehensive process solutions. Krones AG and KHS GmbH hold significant positions in the brewing and beverage niches. Melegari Manghi is renowned for its expertise in the pharmaceutical domain, and Azbil Corporation is recognized for its automation and control solutions.

Global Clean-in-Place Market COVID-19 Impact and Market Status:

The global demand for clean-in-place systems has substantially risen due to the Covid-19 pandemic, mainly propelled by the necessity for improved sanitization and hygiene protocols across different industries on a worldwide scale.

The global COVID-19 pandemic has significantly influenced the Clean-in-Place (CIP) sector. This health crisis has ened concerns regarding hygiene and cleanliness, leading to a surge in demand for advanced cleaning and disinfection methods. The CIP industry, known for its automated cleaning systems utilized in sectors like food and beverage, pharmaceuticals, and dairy, faces a mix of challenges and opportunities. While the temporary closure of manufacturing facilities and supply chain disruptions have impeded market growth, the urgency for stringent cleaning protocols to ensure virus protection has driven the uptake of CIP systems. Manufacturers are now prioritizing the development of innovative and automated cleaning solutions that align with evolving hygiene standards. Moreover, the growing emphasis on environmental sustainability has spurred the incorporation of eco-friendly and energy-efficient features into CIP technologies. Despite the pandemic's initial setbacks, the Clean-in-Place market is poised for recovery and growth in the long term, as industries increasingly prioritize hygiene and safety measures.

Recent Trends & Innovations in the Clean-in-Place Market:

- In July 2020, Ecolab Inc. announced the acquisition of CID Lines, a leading provider of hygiene solutions for the food and beverage industry, strengthening its position in the Clean-in-Place market.

- In January 2019, Diversey, a leading global hygiene and cleaning solutions provider, launched IntelliLinen, an intelligent laundry dispenser system that automates the dosing and monitoring of chemicals used in the Clean-in-Place process.

- In November 2018, SUEZ, a global leader in water and waste management, launched the CLEANOFIL Ultra filtration system for Clean-in-Place applications, providing efficient separation of contaminants from process fluids.

- In October 2018, Alfa Laval, a leading provider of heat transfer, separation, and fluid handling solutions, introduced the ThinkTop V50 and V70, innovative valve control and indication units for hygienic valve clusters used in Clean-in-Place systems.

- In September 2017, Tetra Pak, a multinational food packaging and processing company, launched the Tetra Pak Plant Secure, a comprehensive plant management service that includes Clean-in-Place optimization to enhance operational performance.

- In August 2017, EVOQUA, a leading provider of water treatment solutions, acquired ADI Systems, a provider of industrial wastewater treatment systems, expanding its capabilities in Clean-in-Place wastewater treatment.

Clean-in-Place Market Growth Factors:

Factors driving the growth of the Clean-in-Place industry comprise the growing integration of automated cleaning technologies, strict regulatory mandates regarding cleanliness and safety, and a surge in the need for cleaning solutions that are both effective and economical.

The Clean-in-Place (CIP) industry is poised for substantial growth in the upcoming years. This growth is primarily attributed to the escalating need for robust cleaning techniques in sectors like food and beverage, pharmaceuticals, and biotechnology. Stricter regulations and standards in these sectors necessitate comprehensive cleaning and sterilization processes to uphold product quality and safety, thus propelling the adoption of CIP systems. The increasing emphasis on automation and the desire to minimize manual involvement in cleaning operations have spurred the widespread acceptance of CIP systems, driving market expansion further. Moreover, technological advancements like the incorporation of IoT and data analytics in CIP systems are anticipated to boost market growth by facilitating real-time monitoring and enhancing operational efficiency. Additionally, the rising awareness regarding cleanliness and sanitation among consumers, coupled with a focus on sustainability and water conservation, is fostering the uptake of CIP systems. Consequently, major industry players are investing in research and development endeavors to introduce inventive and environmentally friendly CIP solutions. In conclusion, given the mounting demand for effective and automated cleaning solutions across a range of sectors, the Clean-in-Place market is positioned for significant growth in the foreseeable future.

Clean-in-Place Market Restraining Factors:

The study indicates that primary barriers for the Clean-in-Place industry encompass substantial upfront investment expenses, intricate machinery needs, and restricted adaptability with specific process equipment.

The Clean-in-Place (CIP) industry has experienced substantial growth as a result of the rising need for effective and automated cleaning solutions across various sectors. Nonetheless, there are several factors that could hinder the market's expansion. One key challenge is the significant cost associated with implementing CIP systems, encompassing setup expenses, equipment costs, and ongoing maintenance fees. This financial burden may deter small and medium-sized enterprises from embracing CIP technology, thereby constraining market growth. Another obstacle is the dearth of skilled personnel and expertise in CIP systems, which is crucial for their successful deployment. Certain regions or industries may lack the requisite training and know-how for effective CIP implementation. Additionally, stringent regulations and standards set forth by regulatory bodies can escalate compliance costs for businesses, acting as a hurdle to market advancement. Furthermore, limited awareness regarding the benefits of CIP systems among end-users could impede their adoption. Lastly, the sluggish uptake of CIP systems in emerging economies where traditional cleaning methods are still prevalent presents a challenge to market development. Notwithstanding these obstacles, the Clean-in-Place market displays significant potential and promising outlooks. Industries like food and beverage, pharmaceutical, and dairy are increasingly prioritizing cleanliness and hygiene, fueling the demand for efficient automated cleaning solutions. Technological advancements and the introduction of innovative CIP systems may help overcome some of these challenges by rendering them more cost-efficient, user-friendly, and easier to implement. Moreover, initiatives by governmental entities and industry associations aimed at enhancing operational cleanliness will further propel the growth of the CIP market. With a sustained focus on augmenting operational efficiency, reducing manual labor, and enhancing product quality, the Clean-in-Place sector is poised for robust growth in the foreseeable future.

Key Segments of the Clean-in-Place Market

Offering Overview

• Single-Tank Systems

• Two-Tank Systems

• Multi-Tank Systems

• Others

System Type Overview

• Single-Use CIP Systems

• Reuse CIP Systems

End-User Overview

• Food Industry

• Dairy Industry

• Pharmaceuticals Industry

• Brewery and Beverages Industry

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America