Cold Insulation Materials Market Analysis and Insights:

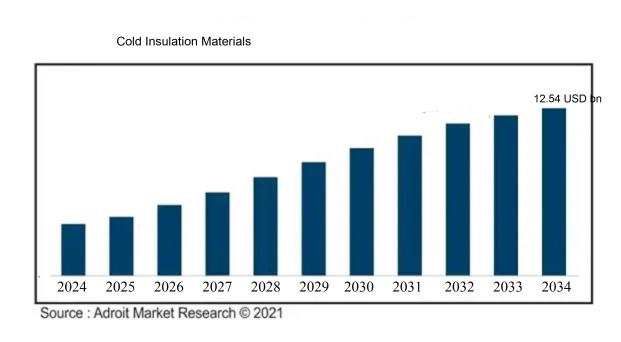

The market for Global Cold Insulation Materials was estimated to be worth USD 7.42 billion in 2024, and from 2025 to 2034, it is anticipated to grow at a CAGR of 4.83%, with an expected value of USD 12.54 billion in 2034.

The market for cold insulation materials is fundamentally influenced by the rising need for energy efficiency across multiple sectors, particularly in refrigeration, petrochemical industries, and cryogenics. Increasing consciousness regarding environmental sustainability, coupled with the enforcement of strict regulations targeting energy use and greenhouse gas emissions, further stimulates growth in this market. Innovations in insulation technology lead to improvements in performance and a reduction in thermal conductivity, which significantly drives demand. Furthermore, the growth of infrastructure and industrial development in developing regions enhances the necessity for reliable cold insulation solutions. The growing inclination towards energy-efficient architectural designs and the transition from conventional insulation methods to advanced materials also support the market's growth. Additionally, fluctuations in energy prices amplify the focus on energy conservation, thereby facilitating the adoption of cold insulation products across diverse industries.

Cold Insulation Materials Market Definition

Cold insulation materials are advanced substances engineered to minimize heat transfer in settings with extremely low temperatures, generally below -50°C. Their primary function is to preserve specific thermal environments crucial for applications like cryogenic storage and transportation.

Cold insulation materials are essential across numerous sectors, serving to uphold low temperatures in areas such as refrigeration, liquefied natural gas (LNG) transport, and chemical processing. These materials are instrumental in reducing thermal losses, thereby enhancing energy efficiency and lowering costs associated with operations. By inhibiting condensation and the formation of ice, they safeguard equipment from potential harm and improve safety by reducing risks linked to temperature variations. Additionally, their effectiveness in cold insulation supports sustainability efforts by diminishing energy consumption, which in turn helps in lowering carbon emissions. In conclusion, the significance of cold insulation materials is evident in their capacity to optimize operational performance, enhance safety measures, and promote energy-efficient practices across a variety of industries.

Cold Insulation Materials Market Segmental Analysis:

Insights On Material

Polyurethane Foam

Based on the latest research and market trends, Polyurethane Foam is expected to dominate the Global Cold Insulation Materials Market. This material is highly valued for its superior thermal resistance, lightweight nature, and versatility, making it ideal for various applications such as refrigeration, HVAC systems, and industrial insulation. Its ability to provide efficient insulation while minimizing energy loss contributes significantly to energy conservation, which is increasingly prioritized in various sectors. Additionally, the rising demand for energy-efficient solutions, coupled with advancements in manufacturing technologies, boosts the popularity of Polyurethane Foam, making it the leading choice among insulation materials.

Fiberglass

Fiberglass is another prominent player in the cold insulation materials market, appreciated for its durability and high thermal performance. It is commonly used in residential and commercial buildings, as well as in industrial applications. Fiberglass insulation is resistant to moisture, which reduces the risk of mold growth and degradation over time. However, while it is effective in insulation, it may not hold the same weight as Polyurethane Foam in terms of market dominance, primarily due to the latter's superior insulation properties.

Polystyrene Foam

Polystyrene Foam is widely recognized for its cost-effectiveness and excellent thermal insulation properties. It is commonly used in both residential and commercial applications, especially in walls and roofs. However, while it provides reasonable insulation performance, it lacks the versatility and efficiency of Polyurethane Foam. Polystyrene Foam also has environmental concerns associated with its production and disposal, which can limit its appeal in a market that increasingly favors eco-friendly materials.

Phenolic Foam

Phenolic Foam is known for its superior fire resistance and thermal performance, making it suitable for specialized applications, especially in industries like aerospace and refrigeration. Although its insulation performance is commendable, the relatively higher production costs and limited applications compared to Polyurethane Foam hinder its market prominence. As industries increasingly prioritize cost-efficient solutions, Phenolic Foam struggles to compete for market share against more versatile materials.

Others

The category of Others encompasses various insulation materials that may not fit neatly into the common classifications. These can include advanced composites and bio-based insulation alternatives. While these materials offer unique properties and certain niche applications, they currently lack the widespread adoption and appeal found in more established options like Polyurethane Foam. Consequently, their contribution to the overall market remains limited, reinforcing Polyurethane Foam’s leading position.

Insights On Insulation Type

Fibrous

Fibrous insulation materials are anticipated to dominate the Global Cold Insulation Materials Market due to their superior thermal performance, lightweight nature, and ease of installation. Fibrous materials, including fiberglass and mineral wool, effectively trap air, thus providing excellent thermal resistance, which is crucial in the cold insulation sector. Their adaptability in various applications, such as pipelines, storage tanks, and refrigeration systems, further enhances their market share. Additionally, the growing demand for energy efficiency and environmental sustainability is bolstered by the use of fibrous materials, as they often have a longer lifespan and are recyclable. These factors will likely position fibrous insulation as the leading choice among insulation types.

Cellular

Cellular insulation materials, such as polyurethane and polystyrene, are widely used for their excellent thermal resistance properties and moisture resistance. Their closed-cell structure provides exceptional insulation performance and prevents water absorption, making them suitable for applications in cold environments. Although they may not dominate the market, cellular materials are crucial for specific applications, especially in the construction and refrigeration industries where energy efficiency is a priority. The growth of the cold logistics sector further supports the use of cellular insulation, although it remains secondary to fibrous materials in overall market demand.

Granular

Granular insulation materials have a more niche application in the cold insulation market, often utilized in specialized situations like grain storage and industrial processing. These materials, often consisting of loose fill components, rely on their air-trapping capabilities to provide thermal insulation. While granular insulation is effective, its limitations in terms of structural integrity and installation ease make it less favorable when compared to fibrous and cellular types. They are typically used in scenarios where flexibility and cost are more crucial than long-term insulation performance, hence placing them behind other types in terms of overall market dominance.

Others

The "Others" category includes a range of alternative insulation materials that do not fit neatly into fibrous, cellular, or granular classifications. This can encompass advanced materials like aerogels or niche products with unique properties. While these materials may show promise in specific applications, they represent a smaller portion of the market due to their higher costs and limited scalability. The overall demand for these alternatives tends to be overshadowed by the established types of insulation, with many consumers opting for tried-and-true solutions that provide reliable performance and cost-efficiency.

Insights On Application

Refrigeration

The refrigeration is anticipated to dominate the Global Cold Insulation Materials Market. This prominence can be attributed to the growing demand for cold chain logistics, especially in food preservation and pharmaceuticals. The increasing emphasis on energy efficiency in refrigeration systems also fuels the need for high-performance insulation materials. Innovations in refrigerants and the rising importance of sustainability in the refrigeration sector further drive the demand and adoption of advanced cold insulation solutions. As businesses strive to maintain product integrity throughout the supply chain and enhance energy efficiency, refrigeration is set to become the leading application area in the market.

HVAC

The HVAC market is another significant application area for cold insulation materials. With the expansion of construction activities and increasing awareness about energy-efficient systems, there is a rising demand for insulating products that can effectively minimize energy loss. Technological advancements in HVAC systems, aimed at improving performance and reducing maintenance costs, further increase the need for high-quality insulation materials. Moreover, the focus on creating comfortable indoor environments in residential, commercial, and industrial buildings strengthens the role of insulation in HVAC applications.

Chemicals

In the chemicals sector, cold insulation materials play a vital role in managing temperature-sensitive processes that require stringent performance standards. Facilities often handle hazardous materials that necessitate effective insulation to ensure safe storage and minimize thermal losses. The rise in chemical manufacturing and processing activities globally, along with regulatory pressures for safety and environmental sustainability, accentuates the need for improved thermal insulation solutions. As the chemical industry continues to grow and innovate, the demand for reliable cold insulation will remain significant.

Oil & Gas

The oil and gas industry is a critical arena for cold insulation materials, particularly in operations involving liquefied natural gas (LNG) and other cryogenic processes. Efficient insulation is paramount to prevent thermal losses and ensure the stability of these substances during transport and storage. With the rise in energy consumption and stringent regulations concerning environmental safety, the need for advanced insulation solutions in pipelines and storage facilities becomes more pronounced. Investments in infrastructure and the increasing exploration of unconventional energy sources further strengthen this application market.

Others

The "Others" category encompasses a variety of applications that also utilize cold insulation materials, including shipping, food processing, and industrial refrigeration. These areas require effective thermal management solutions to maintain product quality, safety, and compliance with regulations. The continuous evolution of industries related to logistics and manufacturing drives the demand for insulation products that perform under varying environmental conditions. While this may not dominate the market, it nevertheless contributes significantly as new uses and technologies emerge, fostering innovation and growth within the broader cold insulation landscape.

Global Cold Insulation Materials Market Regional Insights:

Asia Pacific

Asia Pacific is expected to dominate the Global Cold Insulation Materials market due to a combination of rapid industrial growth, significant investments in infrastructure development, and a surge in the demand for energy-efficient solutions. Countries like China and India are experiencing rapid urbanization and industrialization, leading to increased requirements for refrigeration and temperature-controlled storage. The presence of major manufacturing hubs and growing awareness regarding energy conservation among industries also contribute to the region's dominance. Additionally, government initiatives promoting green building practices and the adoption of eco-friendly materials further bolster the market in Asia Pacific, making it a leading region in cold insulation materials.

North America

North America holds a significant position in the Global Cold Insulation Materials market, chiefly driven by technological advancements and a mature construction industry. The region exhibits robust demand for insulation in the commercial and residential sectors. Furthermore, stringent energy efficiency regulations and an increasing focus on sustainable building practices are propelling the adoption of advanced insulation materials. The presence of established manufacturers and emphasis on R&D further stimulate market growth, ensuring North America's prominent role in cold insulation materials, following Asia Pacific.

Europe

Europe is a key player in the Global Cold Insulation Materials market, characterized by stringent environmental regulations and a strong emphasis on energy efficiency. Countries in this region prioritize sustainable construction and eco-friendly solutions, driving the demand for effective insulation materials. Additionally, the growing need for refrigeration and transport solutions in sectors like pharmaceuticals and food & beverage contributes to market growth. The strong presence of established companies focusing on innovation further enhances Europe’s competitive edge within the cold insulation sector.

Latin America

Latin America demonstrates a growing interest in the Global Cold Insulation Materials market, influenced by the region's expanding industrial base and increasing urbanization. Rising investments in infrastructure projects, including energy and transportation, contribute to the demand for cold insulation materials, particularly in Brazil and Mexico, where such projects are witnessing considerable government attention. The burgeoning construction industry is also a vital contributor to market growth, albeit at a slower pace compared to other regions. However, this region still faces challenges related to economic instability, which may impact growth prospects in the short term.

Middle East & Africa

The Middle East & Africa region is gradually making strides in the Global Cold Insulation Materials market, driven by the rapid growth of the oil and gas sector and the expansion of industrial applications. Countries like UAE and Saudi Arabia are investing heavily in infrastructure and industrial projects, creating growing opportunities for cold insulation. Additionally, increasing demand from the construction sector, alongside the rising awareness of energy efficiency, fuels market development. Despite these growth drivers, the region is challenged by fluctuating economic conditions and varying regulations that may hinder extensive penetration of cold insulation materials.

Cold Insulation Materials Competitive Landscape:

Leading figures in the worldwide cold insulation materials sector are spearheading advancements and product innovation, emphasizing improvements in thermal efficiency and energy conservation. These players are also forming strategic alliances and broadening their market footprint to cater to the rising demand spanning multiple industries such as oil and gas, refrigeration, and HVAC.

Prominent participants in the Cold Insulation Materials Market consist of Owens Corning, Armacell International S.A., Johns Manville, BASF SE, Kingspan Group, Rockwool International A/S, Dow Inc., Insulation Solutions, Saint-Gobain S.A., K-Flex, 3M Company, Celotex, Sika AG, and Boardman LLC.

Global Cold Insulation Materials COVID-19 Impact and Market Status:

The Covid-19 pandemic had a profound impact on the Global Cold Insulation Materials market, leading to disruptions in supply chains and a decline in demand across multiple industries, especially during periods of lockdown.

The COVID-19 pandemic had a profound effect on the market for cold insulation materials, primarily due to supply chain interruptions and a decrease in construction activities. Lockdowns and restrictions across numerous areas posed operational obstacles for production facilities, resulting in a decline in the manufacture of cold insulation products such as polyurethane and polystyrene. Moreover, numerous construction projects were either postponed or completely halted, leading to diminished demand from important sectors like refrigeration, air conditioning, and industrial insulation. Nonetheless, the pandemic underscored the critical need for energy efficiency and effective temperature management across various industries. This realization has fostered a gradual market recovery and an increased emphasis on sustainable construction practices in the aftermath of the pandemic. As economies begin to reopen and construction activities pick up again, the market is anticipated to bounce back, propelled by a renewed focus on resilient and energy-efficient insulation solutions essential for addressing future health emergencies and environmental concerns.

Latest Trends and Innovation in The Global Cold Insulation Materials Market:

- In November 2022, BASF SE announced the launch of a new line of XPS (extruded polystyrene) products aimed at enhancing thermal insulation performance while reducing environmental impact. This innovation aligns with BASF’s commitment to sustainability in construction.

- In January 2023, Kingspan Group acquired the insulation business of German company Isover, aiming to expand its market presence in Europe and strengthen its R&D capabilities focused on advanced insulation technologies.

- In March 2023, Rockwool International A/S reported the development of a new type of stone wool insulation that incorporates recycled materials, which improves thermal resistance while promoting circular economy principles in the insulation industry.

- In June 2023, Owens Corning launched an innovative cold insulation solution known as Foamglas, which features a unique closed-cell structure designed for improved energy efficiency in industrial applications.

- In August 2023, Armacell International S.A. introduced a new range of elastomeric insulation products with enhanced thermal performance while achieving a significant reduction in weight, targeting both commercial and residential markets.

- In September 2023, Saint-Gobain announced a strategic partnership with a tech firm to invest in developing smart insulation materials that leverage IoT technology, enhancing building energy management systems.

- In October 2023, Thermo-Guard Inc. revealed its proprietary reflective insulation technology that significantly reduces heat transfer, aiming at both residential and commercial applications to meet changing energy efficiency standards.

Cold Insulation Materials Market Growth Factors:

The expansion of the Cold Insulation Materials Market is propelled by a rising need for enhanced energy efficiency in various industries, alongside innovations in insulation technology.

The Cold Insulation Materials Market is witnessing robust expansion, influenced by several crucial factors. A significant driver of this growth is the rising demand for energy-efficient systems in sectors such as HVAC, refrigeration, and petrochemicals, as companies strive to lower energy usage and minimize greenhouse gas emissions. There is also a growing emphasis on sustainable construction, which has led to an increased use of innovative insulation materials aimed at enhancing energy efficiency in buildings.

In addition, the rapid development of the industrial sector in emerging economies is fueling the requirement for cold insulation solutions that improve efficiency in temperature-critical processes. Advances in insulation technologies, including the introduction of polyurethane foam and polystyrene, provide exceptional thermal resistance and durability, further facilitating market growth.

Furthermore, stringent regulations implemented by governments to decrease carbon emissions and promote energy efficiency are motivating industries to adopt cold insulation technologies. The escalating demand for dependable cold chain logistics, particularly within the food and pharmaceutical industries, also plays a significant role in market expansion, as insulated transport solutions are essential for preserving product quality.

Overall, these factors converge to shape the dynamic landscape of the cold insulation materials sector, highlighting a momentum towards enhanced energy efficiency and sustainability across a variety of industries.

Cold Insulation Materials Market Restaining Factors:

Critical limitations in the Cold Insulation Materials Industry encompass elevated raw material expenses and rigorous environmental regulations that influence manufacturing methods.

The Cold Insulation Materials Market is confronted with numerous challenges that may impede its progress. A notable obstacle is the significant expense associated with advanced materials, which can hinder their acceptance, especially in developing countries where budget constraints are a priority. Additionally, stringent environmental regulations regarding the manufacturing and disposal of specific insulation materials can create further limitations, requiring companies to balance compliance with sustainable profitability. The instability of raw material costs also disrupts production consistency, affecting the overall landscape of the market. Furthermore, the emergence of competing insulation solutions, like vacuum insulated panels and aerogels, may redirect investment and focus away from conventional cold insulation options. There is also a prevalent lack of awareness regarding the advantages of cold insulation in particular applications, resulting in diminished demand in various sectors. However, continual progress in material science and an increasing emphasis on energy efficiency offer promising avenues for innovation and market growth. As manufacturers strive to create environmentally friendly and economically viable products, the Cold Insulation Materials Market is poised to adapt to these obstacles, leading to a more sustainable and efficient future.

Key Segments of the Cold Insulation Materials Market

By Material

• Fiberglass

• Polyurethane Foam

• Polystyrene Foam

• Phenolic Foam

• Others

By Insulation Type

• Fibrous

• Cellular

• Granular

• Others

By Application

• HVAC

• Chemicals

• Oil & Gas

• Refrigeration

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America