Market Analysis and Insights:

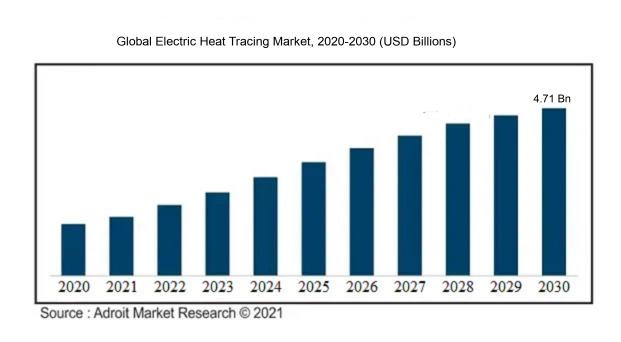

The market for Global Electric Heat Tracing was estimated to be worth USD 2.31 billion in 2021, and from 2022 to 2030, it is anticipated to grow at a CAGR of 8.17%, with an expected value of USD 4.71 billion in 2030.

The Electric Heat Tracing Market experiences significant growth due to various factors. One key driver is the rising demand for energy-efficient solutions to maintain temperatures in industries like oil and gas, chemicals, and power generation. Electric heat tracing systems offer precise control and lower energy consumption, making them a popular choice for thermal management.

Additionally, there is an increasing need for freeze protection and maintaining process temperatures in harsh weather conditions, supporting market expansion. Strict regulations focusing on workplace safety and accident prevention, coupled with increasing awareness of electric heat tracing benefits, are also boosting market growth. Technological advancements, such as digital heat tracing systems with real-time monitoring and remote control features, contribute to market progress. Furthermore, the growing investments in infrastructure development in emerging economies offer favorable opportunities for market players. Overall, these factors combined drive the growth of the electric heat tracing market.

Electric Heat Tracing Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2030 |

| Study Period | 2018-2030 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2030 | USD 4.71 billion |

| Growth Rate | CAGR of 8.17% during 2022-2030 |

| Segment Covered | By Type, By Components, By Application, By Vertical, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Thermon Group Holdings Inc., Pentair plc, Raychem (Tyco), Emerson Electric Co., Chromalox (Spiral), eltherm GmbH, Heat Trace Limited, BriskHeat Corporation, Bartec, Drexan Energy Systems Inc., Danfoss, Spirax-Sarco Engineering plc, nVent, Garland Manufacturing Company, and Anvil International. |

Market Definition

Electric heat tracing is a sophisticated method that employs electrical wiring to produce heat, ensuring the preservation or elevation of temperatures in pipes, tanks, or various machinery to prevent freezing or heat loss. This technology is predominantly utilized in industrial and commercial settings where precise heat control is imperative.

The utilization of electric heat tracing is vital for the maintenance of optimal temperatures in various industrial settings, including oil and gas, chemical, and food processing industries. This technique involves integrating electrical heating components along pipelines and equipment to prevent heat dissipation, thereby facilitating consistent temperature control to prevent issues like freezing, condensation, and obstruction. Electric heat tracing is significant in safeguarding the quality of transported substances, improving operational efficiency, and decreasing energy consumption. Furthermore, it enhances safety by averting accidents and equipment failures stemming from extreme temperatures, thereby reducing downtime and maintenance requirements. In essence, electric heat tracing is essential for ensuring the seamless operation and efficiency of industrial processes.

Key Market Segmentation:

Insights On Key Type

Self-Regulating

The Self-Regulating type is expected to dominate the Global Electric Heat Tracing Market. Self-regulating heating cables offer a flexible and efficient solution for maintaining temperature in various applications. These cables automatically adjust their heat output based on the surrounding conditions, ensuring energy efficiency and preventing overheating. Their self-regulating feature allows them to monitor the heat requirements of the system and adjust accordingly, making them suitable for a wide range of industries. With increasing demand for energy-efficient and cost-effective heat tracing systems, the self-regulating part is projected to dominate the market.

Constant Wattage

Constant Wattage heating cables are another significant type of the Global Electric Heat Tracing Market. These cables provide a consistent and uniform heat output throughout their length. They are commonly used in applications where a consistent and specific temperature maintenance is required, such as freeze protection or process temperature control. While not expected to dominate the market, constant wattage heating cables continue to have a significant presence due to their reliability and suitability for specific applications.

Mineral-insulated

Mineral-insulated heating cables offer high-performance solutions for electric heat tracing systems. These cables consist of a resistance wire embedded in magnesium oxide insulation and covered with a metallic sheath, providing excellent thermal conductivity and mechanical strength. Mineral-insulated cables are commonly used in harsh and extreme environments, as they can withstand high temperatures and are resistant to corrosion and physical damage. Although not projected to dominate the market, the mineral-insulated part holds a significant share due to its suitability for demanding applications where durability and performance are crucial.

Skin Effect

The Skin Effect type within the Global Electric Heat Tracing Market is expected to have a relatively smaller presence compared to other parts. Skin effect heating cables utilize a unique design where the current is mainly concentrated on the surface of the cable, resulting in efficient heat transfer. These cables are often used in applications with limited space or where the heat tracing needs to be discreet. However, their utilization is more specific and limited compared to other types of heat tracing cables, leading to a smaller market share. Although not dominating, the skin effect part offers benefits in certain niche applications.

Insights On Key Component

Thermal Insulation Materials

Thermal insulation materials are expected to dominate the global electric heat tracing market. These materials play a crucial role in maintaining the desired temperature in various industrial processes and applications. The insulation materials help in reducing heat loss and preventing energy wastage, making them an essential component in electric heat tracing systems. With the increasing focus on energy efficiency and sustainability, the demand for effective thermal insulation materials is expected to witness significant growth. Additionally, advancements in insulation technologies and the need for improved performance are further driving the dominance of thermal insulation materials in the electric heat tracing market.

Electric Heat Tracing Cables

Electric heat tracing cables form an integral component of the electric heat tracing systems. These cables are designed to provide heat to pipes, vessels, and equipment, preventing them from freezing or maintaining process temperature. While they play a vital role in the overall system, the dominance of electric heat tracing cables is relatively lower compared to other components. Factors such as advancements in control and monitoring systems, focus on energy efficiency, and the importance of thermal insulation materials contribute to the reduced dominance of electric heat tracing cables in the global market.

Power Connection Kits

Power connection kits are essential for connecting the electric heat tracing systems to the power source. They include components such as junction boxes, cable glands, connectors, and termination kits. Although power connection kits are crucial components for the functioning of the electric heat tracing systems, their dominance is relatively lower compared to other components. The focus of the market is shifting towards the advancements in control and monitoring systems and the need for effective thermal insulation materials, contributing to the reduced dominance of power connection kits in the global market.

Control and Monitoring Systems

Control and monitoring systems play a crucial role in the efficient operation of electric heat tracing systems. These systems enable real-time monitoring, temperature control, and optimization of the heat tracing process. With the increasing emphasis on automation and control, the demand for advanced control and monitoring systems is expected to grow. However, the dominance of control and monitoring systems is not as high as thermal insulation materials. The importance of insulation materials in achieving energy efficiency and the overall performance of electric heat tracing systems makes them a more critical component in the market.

Others

The Others category consists of various components that may have a relatively limited presence or impact in the global electric heat tracing market. These components can include accessories, ancillary products, or specialized components that have niche applications or are required in specific industries. Although they contribute to the overall functioning of electric heat tracing systems, the dominance of this part is expected to be lower compared to thermal insulation materials or control and monitoring systems. The market focus on energy efficiency, insulation, and advanced control technologies contributes to the reduced dominance of the "Others" part in the global market.

Insights On Key Application

Freeze Protection & Process Temperature Maintenance

The Freeze Protection & Process Temperature Maintenance application is expected to dominate the Global Electric Heat Tracing Market. This is due to the increasing demand for electric heat tracing systems for maintaining the temperature of industrial processes and protecting critical equipment against freezing in various industries such as oil and gas, chemical, and food processing. The Freeze Protection & Process Temperature Maintenance part offers cost-effective and efficient solutions for controlling temperature and preventing damage, making it a crucial application area for electric heat tracing systems.

Roof & Guttering De-icing

The Roof & Guttering De-icing application, although not expected to dominate the Global Electric Heat Tracing Market, holds significant importance. This part caters to the needs of residential, commercial, and industrial buildings by preventing the accumulation of ice and snow on roofs and gutters. The demand for roof and gutter de-icing systems has been increasing in regions with cold climates, where ice dams and icicles pose a risk to building structures. Electric heat tracing systems for roof and gutter de-icing offer reliable and efficient solutions to prevent damage caused by ice buildup, providing safety and convenience to users.

Floor Heating

The Floor Heating application, while not projected to dominate the Global Electric Heat Tracing Market, is a relevant application area with growing demand. This part focuses on providing warmth and comfort to residential and commercial spaces by installing electric heat tracing systems beneath floors. The trend of using radiant floor heating systems has been on the rise due to their energy efficiency, uniform heating distribution, and elimination of the need for traditional heating devices. The Floor Heating part contributes to creating cozy and comfortable indoor environments in various settings, making it an appealing option for those seeking innovative heating solutions.

Others

The Others category encompasses diverse application areas within the Global Electric Heat Tracing Market that do not fall under the dominant or previously mentioned parts. This part may include applications such as pipe freeze protection, tank heating, snow melting, and more. While the specific parts within "Others" may have their own niche importance, they are not expected to dominate the overall market. However, they play a significant role in meeting specific heating requirements in various industries, offering tailored solutions to address unique needs and challenges.

Insights On Key Vertical

Oil & Gas

The Oil & Gas industry is expected to dominate the Global Electric Heat Tracing Market. This is primarily due to the extensive use of electric heat tracing systems in the oil and gas industry for the purpose of maintaining optimal temperature in pipelines, tanks, and equipment. With the increasing exploration and production activities in the oil and gas sector, the demand for electric heat tracing systems is projected to be the highest among all the parts.

Chemical

The Chemical industry holds a significant share in the Global Electric Heat Tracing Market. The chemical industry extensively utilizes electric heat tracing systems to prevent freezing and maintain process temperature in pipes, reactors, and storage tanks. The wide range of applications in the chemical industry such as maintaining viscosity, preventing crystallization, and heat-up processes contribute to the dominance of this part.

Commercial

In the Commercial industry, electric heat tracing systems find applications in various sectors such as hospitality, offices, retail, and public buildings. These systems are used to prevent ice and snow buildup on roofs, gutters, and walkways, ensuring a safe environment for staff and customers. Although the commercial sector represents a significant portion of the market, it is not expected to dominate the Global Electric Heat Tracing Market.

Residential

The Residential industry includes applications of electric heat tracing systems in residential buildings, particularly for protecting water pipes from freezing and maintaining optimal temperature for indoor plumbing systems. While this part has its importance, it is not anticipated to dominate the Global Electric Heat Tracing Market due to the comparatively smaller scale of residential projects compared to other sectors.

Power & Energy

The Power & Energy industry plays a crucial role in the Global Electric Heat Tracing Market. Electric heat tracing systems are widely employed in power plants, renewable energy installations, and transmission infrastructure to ensure the continuous and efficient operation of critical components in diverse weather conditions. The demand for heat tracing systems in this part is expected to be significant but not dominant compared to the Oil & Gas part.

Food & Beverage

The Food & Beverage part is a notable in the Global Electric Heat Tracing Market. Electric heat tracing systems are utilized in this industry to maintain temperature control during storage, processing, and transportation of perishable goods. The demand for heat tracing systems in the food and beverage sector is expected to be substantial, but it is not projected to dominate the overall market.

Pharmaceutical

The Pharmaceutical industry of the Global Electric Heat Tracing Market is significant, as the industry requires precise temperature control for various manufacturing processes and storage conditions. Electric heat tracing systems are employed to maintain specific temperatures in pharmaceutical facilities, including laboratories, cleanrooms, and cold chain logistics. While this part has its importance, it is not expected to dominate the Global Electric Heat Tracing Market.

Water & Wastewater Treatment

The Water & Wastewater Treatment industry is crucial in the Global Electric Heat Tracing Market. Electric heat tracing systems play a vital role in preventing freezing and maintaining optimal temperature in pipes and storage tanks used in water and wastewater treatment facilities. This part is anticipated to have a notable share in the market but not dominate it compared to the Oil & Gas part.

Others

The Others category consists of various industries that utilize electric heat tracing systems for specific applications, such as telecommunications, mining, and transportation. Although the demand for heat tracing systems exists in these sectors, they are not expected to dominate the Global Electric Heat Tracing Market compared to the Oil & Gas part.

Insights on Regional Analysis:

Asia Pacific

The Asia Pacific region is expected to dominate the Global Electric Heat Tracing Market. With rapid industrialization and urbanization across countries like China, India, and Japan, there is a significant increase in the demand for electric heat tracing systems. The region is witnessing a rising focus on energy-efficient solutions and the implementation of stringent regulations to promote sustainable heating practices. Moreover, the presence of major heat tracing system manufacturers, coupled with the growing number of infrastructure projects and the expansion of industries requiring heat tracing, further boosts the market in the Asia Pacific region.

North America

In North America, the electric heat tracing market is poised for substantial growth. The region has a well-established industrial sector and a high adoption rate of advanced technologies. The presence of a mature oil and gas industry, chemical manufacturing facilities, and a significant demand for residential and commercial heating solutions contribute to the market's growth. Additionally, stringent safety regulations and a focus on energy-efficient heating systems drive the deployment of electric heat tracing solutions in North America.

Europe

Europe is another prominent region in the Global Electric Heat Tracing Market. The presence of well-developed industries such as oil and gas, chemical, food and beverage, and pharmaceuticals, combined with a high emphasis on energy conservation, fuels the demand for electric heat tracing systems in the region. The European Union's strict regulations pertaining to energy efficiency and carbon emissions play a crucial role in encouraging the adoption of electric heat tracing technology. Moreover, the region has a strong base of manufacturers offering innovative heat tracing solutions, further supporting market growth.

Latin America

Latin America is witnessing a steady growth trajectory in the electric heat tracing market. The region's expanding industrial sector, including oil and gas, petrochemicals, and energy, drives the demand for electric heat tracing systems. Additionally, the growing focus on adopting energy-efficient solutions and improving operational safety in industrial processes contributes to market growth in Latin America. Furthermore, investments in infrastructure development and the expansion of residential and commercial buildings propel the adoption of electric heat tracing technology in the region.

Middle East & Africa

The Middle East & Africa region shows promising potential in the electric heat tracing market. With a significant presence of oil and gas facilities, chemical industries, and power generation plants, the demand for heat tracing systems is on the rise. The region's extreme climate conditions and a focus on maintaining optimal operational conditions in industrial processes further drive the adoption of electric heat tracing technology. However, challenges related to limited awareness, low industrial development in some areas, and economic volatility may impact the market's growth to some extent. Nonetheless, the Middle East & Africa region holds opportunities for market players to tap into its growing demand for electric heat tracing solutions.

Company Profiles:

Prominent contributors in the international electric heat tracing industry significantly contribute to the creation of inventive and sustainable heat tracing solutions to address the increasing needs across diverse sectors including oil & gas, power generation, and chemicals. These entities prioritize product innovation, strategic collaborations, and geographic reach as part of their strategy to achieve a competitive advantage and bolster their market presence.

Prominent companies in the Electric Heat Tracing industry include Thermon Group Holdings Inc., Pentair plc, Raychem (Tyco), Emerson Electric Co., Chromalox (Spiral), eltherm GmbH, Heat Trace Limited, BriskHeat Corporation, Bartec, Drexan Energy Systems Inc., Danfoss, Spirax-Sarco Engineering plc, nVent, Garland Manufacturing Company, and Anvil International. These industry leaders are actively engaged in the design, production, and dissemination of electric heat tracing technologies and solutions tailored to diverse sectors such as oil and gas, chemical processing, power generation, and food and beverage industries. These enterprises are committed to enhancing their market presence and competitive advantages on a global scale by prioritizing innovation, product advancement, strategic partnerships, and expansion into new regions.

COVID-19 Impact and Market Status:

The Global Electric Heat Tracing market has experienced notable effects from the Covid-19 pandemic, resulting in reduced demand as a consequence of economic deceleration and supply chain interruptions.

The global health crisis brought about by the COVID-19 pandemic has had a notable impact on the electric heat tracing industry. This sector has witnessed a mix of favorable and adverse consequences as a result of the ongoing situation. Heightened emphasis on cleanliness and sanitation practices has resulted in an increased demand for heat tracing solutions in critical domains like healthcare, pharmaceutical production, and food processing. These sectors require precise temperature management to uphold the quality and safety standards of their products. Conversely, the economic downturn triggered by the pandemic has negatively influenced construction and infrastructure projects, which are key consumers of electric heat tracing systems. Disruptions in supply chains and a decrease in available workforce have impeded the manufacturing and installation processes of these systems. Furthermore, travel restrictions and social distancing protocols have constrained the feasibility of conducting on-site inspections and maintenance activities, consequently impacting the post-sales services. Despite these obstacles, it is anticipated that the electric heat tracing market will gradually rebound in the forthcoming years as economic operations regain traction and the prioritization of health and safety perseveres.

Latest Trends and Innovation:

- nVent Electric plc announced the acquisition of Ventois, a provider of electric heat tracing solutions, on March 23, 2021.

- Pentair plc introduced its Raychem SENZ range of control and monitoring products for electric heat tracing systems on May 12, 2020.

- Thermon Group Holdings, Inc. completed the acquisition of 100% of the equity interests of CCI Thermal Technologies Inc. on September 15, 2020.

- Emerson Electric Co. launched its WirelessHART Self-Regulating Heat Trace Controller on April 7, 2021.

Significant Growth Factors:

The expansion of the Electric Heat Tracing Market can be credited to the rise in industrial activities and the demand for effective and dependable heating systems.

The electric heat tracing industry is poised for significant growth in the near future due to a variety of driving factors. One key factor is the rising prevalence of electric heat tracing systems in sectors such as oil and gas, chemical, and power generation, which play a vital role in ensuring the proper temperature maintenance of pipelines, tanks, and vessels, thereby preventing product spoilage or freezing. Additionally, stringent safety regulations mandated by governments and the necessity to comply with safety standards and protocols are boosting the demand for electric heat tracing systems. The expansion of the chemical sector and the surging demand for petrochemical goods are also contributing to the market's expansion. The increasing emphasis on energy-efficient solutions and endeavors to reduce energy consumption in industrial operations are further accelerating the adoption of electric heat tracing systems. Moreover, ongoing technological innovations, including the introduction of self-regulating heating cables that offer improved efficiency and adaptability, are poised to drive market growth. In essence, the electric heat tracing sector is set to experience substantial expansion, driven by its diverse applications across industries and the growing focus on safety and energy conservation.

Restraining Factors:

The electric heat tracing market may face constraints due to its restricted implementation in specific developing territories.

The Electric Heat Tracing Market has seen substantial growth recently due to the rising need for efficient heating solutions and the increased use of electric heat tracing systems in diverse industries. However, there are various factors that could impede market expansion. The high initial investment required for electric heat tracing systems can hinder small and medium-sized businesses from adopting this technology. Moreover, the installation and maintenance complexity may present challenges necessitating specialized expertise.

Furthermore, the presence of alternative heating solutions such as steam tracing and self-regulating heat tracing systems could pose a competitive threat to the electric heat tracing market. Lack of awareness about the benefits of electric heat tracing systems among end-users could also hinder market growth. Additionally, stringent regulatory requirements and compliance standards related to the operation and installation of electric heat tracing systems could act as deterrents to market development. Nevertheless, the electric heat tracing market is projected to experience steady growth driven by the increasing focus on energy efficiency, technological advancements, and growing demand from industries such as oil and gas, chemical, and food processing. Through ongoing innovations and educational initiatives aimed at informing end-users about the advantages of electric heat tracing systems, the market is poised to overcome these challenges and thrive in the future.

Key Segments of the Electric Heat Tracing Market

Type Overview

• Self-Regulating Electric Heat Tracing

• Constant Wattage Electric Heat Tracing

• Mineral-insulated Electric Heat Tracing

• Skin Effect Electric Heat Tracing

Component Overview

• Electric Heat Tracing Cables

• Power Connection Kits

• Control and Monitoring Systems

• Thermal Insulation Materials

• Others

Application Overview

• Freeze Protection & Process Temperature Maintenance

• Roof & Guttering De-icing

• Floor Heating

• Others

Vertical Overview

• Oil & Gas

• Chemical

• Commercial

• Residential

• Power & Energy

• Food & Beverage

• Pharmaceutical

• Water & Wastewater Treatment

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America