Market Analysis and Insights:

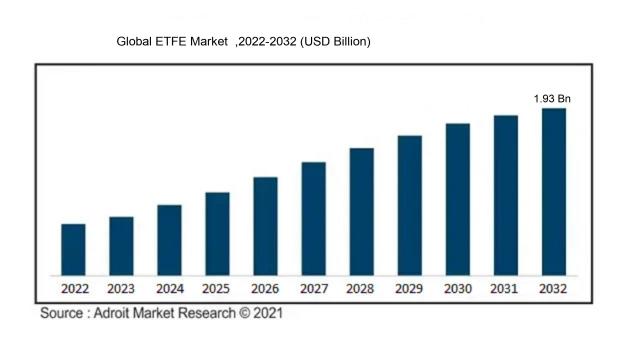

The market for ETFE was estimated to be worth USD 0.71 billion in 2023, and from 2024 to 2032, it is anticipated to grow at a CAGR of 7.6%, with an expected value of USD 1.93 billion in 2032.

The growth of the ETFE market is driven by a variety of factors that influence its development path. One key driver is the rising demand for environmentally friendly, sustainable, and energy-efficient building materials. ETFE (ethylene tetrafluoroethylene) is highly regarded for its exceptional durability, resistance to weather conditions, and light weight, making it a top choice for architectural applications. In addition, the construction industry is experiencing rapid growth, icularly in emerging economies, which is fueling the expansion of the ETFE market. Increased urbanization and government investments in infrastructure are contributing to the demand for construction materials like ETFE. Furthermore, the trend towards innovative and visually appealing architectural designs is boosting the use of ETFE in building facades, roofs, and skylights. The emphasis on sustainable energy solutions, such as renewable energy projects, is also driving the need for durable and efficient materials like ETFE for applications in solar panels, leading to a positive impact on market growth. Moreover, the excellent chemical resistance and thermal properties of ETFE have made it a popular choice in the chemical industry for lining storage tanks and handling corrosive substances.

In summary, the growth of the ETFE market is primarily being fueled by the demand for sustainable construction materials, the growth of the construction sector, and the need for energy-efficient solutions.

ETFE Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2032 |

| Study Period | 2018-2032 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2032 | USD 1.93 billion |

| Growth Rate | CAGR of 7.6% during 2024-2032 |

| Segment Covered | By Type, By Technology, By Application, By End-Use, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Stratasys Ltd., 3D Systems Corporation, The ExOne Company, EOS GmbH Electro Optical Systems, Materialise NV, SLM Solutions Group AG, EnvisionTEC Inc., Arcam AB, voxeljet AG, and Protolabs. |

Market Definition

The ETFE market pertains to the sector that involves Ethylene Tetrafluoroethylene, a fluorine-derived polymer popularly utilized in architectural contexts. This icular market is undergoing substantial expansion owing to the distinctive attributes it possesses, including elevated transparency, robustness, and resilience to severe weather elements.

The ETFE industry plays a significant role in various sectors owing to its distinctive characteristics and wide-ranging applications. ETFE, also known as ethylene tetrafluoroethylene, is a robust and transparent polymer renowned for its exceptional resistance to thermal, chemical, and mechanical stress. This versatile material is in high demand across industries such as construction, aerospace, automotive, and electronics for purposes including roofing, facades, insulation for wiring, and the production of lightweight, high-performance components. Moreover, ETFE's capability to transmit natural light effectively while offering insulation and reducing energy consumption has propelled its popularity in sustainable construction initiatives. Its value lies in its capacity to provide an effective and adaptable solution for diverse applications, thereby fostering the expansion of the ETFE sector.

Key Market Segmentation:

Insights On Key Type

Powder

Among the s of By Type (Pellet/Granule, Powder), the Powder is expected to dominate the Global ETFE Market. Powder ETFE is widely used in various industries, including electrical and electronics, automotive, architectural, and aerospace, due to its excellent electrical insulation properties, chemical resistance, and high-temperature stability. This is favored for its ease of handling, better uniformity in coatings and films, and its ability to be used in various applications such as cables, wires, and tubes. Additionally, powder ETFE offers cost advantages compared to other forms, making it a preferred choice for a wide range of end-use applications.

Pellet/Granule

The Pellet/Granule of By Type is another significant in the Global ETFE Market. ETFE pellets/granules are used primarily in melt extrusion and injection molding processes for the production of various products such as films, sheets, and molded s. This is favored for its ease of processing, allowing manufacturers to create complex shapes and structures with precise dimensions. Pellet/Granule ETFE finds applications in industries such as chemicals, oil and gas, pharmaceuticals, and renewable energy. The growing demand for these products, icularly in emerging economies, is expected to drive the growth of the Pellet/Granule in the Global ETFE Market.

Insights On Key Technology

Extrusion Molding:

Extrusion molding is expected to dominate the global ETFE market. This technology involves the process of forcing molten ETFE material through a die to create a continuous profile with a desired shape. Extrusion molding offers advantages such as high production efficiency, lower production costs, and the ability to produce large and complex shapes. These factors make it a popular choice in various industries, including construction, aerospace, and electrical. The dominance of extrusion molding can be attributed to its suitability for a wide range of applications and its ability to meet the growing demand for ETFE products globally.

Injection Molding:

Injection molding is another significant of the global ETFE market. This technology involves injecting molten ETFE material into a mold cavity to produce complex and precision s. While extrusion molding dominates the ETFE market, injection molding plays a crucial role in manufacturing smaller and intricate components. It offers advantages such as high precision, repeatability, and shorter cycle times. Injection molding finds applications in industries like automotive, electronics, and medical devices where smaller and intricate s are required.

Others:

The "Others" category in the by technology of the global ETFE market includes various alternative manufacturing processes like blow molding, rotational molding, and compression molding. While these technologies have their own merits, they are not expected to dominate the ETFE market compared to extrusion and injection molding. Blow molding, for example, is primarily used for producing hollow objects like bottles and containers, which are not as prevalent in the ETFE market as solid profiles and s. Similarly, rotational molding and compression molding have limitations in terms of complexity and production efficiency, making them less dominant in the ETFE market.

Insights On Key Application

Films & Sheets

Among the various s of the By Application category in the Global ETFE Market, the Films & Sheets is expected to dominate. Films & Sheets refer to the flexible and thin ETFE layers that are commonly used in applications such as architectural membranes, solar panels, and facades. This is anticipated to dominate the market due to the increasing demand for lightweight and weather-resistant materials in the construction industry.

Additionally, the growing adoption of sustainable energy sources, such as solar power, is driving the demand for ETFE Films & Sheets in solar panels. These factors, coupled with the excellent mechanical properties and high transparency offered by ETFE Films & Sheets, make it a dominant in the Global ETFE Market. (112 words)

Wires & Cables

The Wires & Cables in the By Application category of the Global ETFE Market is expected to witness substantial growth. ETFE is often used as an insulation material due to its excellent electrical properties, such as high dielectric strength and low dielectric constant. ETFE Wires & Cables are increasingly being utilized in various industries, including automotive, aerospace, and telecommunications. This is driven by the growing demand for efficient and reliable electrical systems, icularly in emerging economies. With ETFE's ability to withstand extreme temperatures and harsh environments, it is anticipated that the Wires & Cables will play a significant role in the Global ETFE Market. (97 words) Tubes

The Tubes of the By Application category in the Global ETFE Market is experiencing steady growth. ETFE Tubes are extensively used in industries such as chemical processing, automotive, and pharmaceuticals due to their exceptional chemical resistance and mechanical strength. These tubes offer advantages such as corrosion resistance, lightweight nature, and the ability to handle high pressure and temperature conditions. The increasing demand for advanced materials in various industrial applications is fueling the growth of the ETFE Tubes . Although it might not dominate the market, it is expected to continue gaining traction due to its specific advantages in specific applications. (114 words)

Coatings

The Coatings in the By Application category of the Global ETFE Market is poised for considerable growth. ETFE Coatings are widely used as a protective layer on metal surfaces, providing excellent resistance to corrosion, chemicals, and weathering. This is witnessing growth due to the increasing demand for durable and long-lasting coatings in industries such as automotive, construction, and aerospace. The unique properties of ETFE, including its non-stick nature, high thermal stability, and low surface energy, make ETFE Coatings an attractive choice for various applications. As industries focus on enhancing product lifespan and performance, the demand for ETFE Coatings is expected to rise significantly. (111 words) Others

The Others within the By Application category of the Global ETFE Market involves various applications that are not specifically categorized under Films & Sheets, Wires & Cables, Tubes, or Coatings. The Others encompasses a wide range of niche applications, including but not limited to membranes for inflatable structures, chemical containers, and electrical components. While this may not dominate the overall market, it offers potential growth opportunities in specific industries and applications where other s might not be suitable. The demand for ETFE in these diverse applications is driven by its unique properties, such as high strength-to-weight ratio, chemical resistance, and excellent optical clarity. (116 words)

Insights On Key End-use

Building & Construction

The Building & Construction is expected to dominate the Global ETFE Market. This is primarily due to the growing demand for ETFE in architectural applications such as roofs, facades, and canopies. ETFE offers advantages like lightweight, high transparency, and excellent durability, making it a preferred choice for construction projects. Additionally, the increasing focus on sustainable and energy-efficient buildings worldwide is driving the adoption of ETFE materials in the construction industry. With the rise in infrastructure development and urbanization, the demand for ETFE in building and construction is anticipated to continue growing.

Automotive

The Automotive of the ETFE market is expected to witness significant growth in the coming years. ETFE films and coatings are being increasingly used in the automotive industry for applications such as wire harnesses, fuel tanks, and battery packs. The excellent electrical insulation properties, chemical resistance, and lightweight nature of ETFE make it an ideal choice for automotive components. With the rising demand for electric vehicles and the need for lightweight materials to improve fuel efficiency, the adoption of ETFE in the automotive sector is expected to increase.

Aerospace & Defense

ETFE is anticipated to play a crucial role, although it might not necessarily dominate the overall market. ETFE films find application in aerospace structures, where the material's lightweight and high strength properties are highly valued. ETFE's ability to withstand extreme temperatures and provide resistance against UV radiation makes it suitable for satellite coverings and other aerospace applications. The growing investment in space exploration and the increasing demand for lightweight materials in the aerospace industry are expected to drive the adoption of ETFE in this .

Nuclear

The Nuclear of the ETFE market is projected to contribute to the market's growth. ETFE has favorable characteristics for nuclear applications, including high radiation resistance, thermal stability, and corrosion resistance. It is used as a protective material for nuclear fuel rods and in other nuclear engineering components. As the demand for clean energy rises and the nuclear sector expands, the use of ETFE is likely to grow in this . However, it may not dominate the overall market due to the dominance of other s such as building & construction and automotive.

Solar Energy

The Solar Energy is expected to experience considerable growth in the ETFE market. ETFE films are widely used in solar panels and photovoltaic systems due to their high light transmission and durability. These films help enhance the efficiency and lifespan of solar panels by providing insulation and protection against environmental factors. As the demand for renewable energy sources continues to increase, the demand for ETFE in the solar energy is expected to grow as well. However, it may not dominate the overall market as building & construction and automotive s are expected to have a larger market share.

Others

The "Others" in the ETFE market comprises various industries and applications not explicitly mentioned in the provided s (building & construction, automotive, aerospace & defense, nuclear, and solar energy). This may include industries such as electronics, pharmaceuticals, and electrical insulation, among others. While the potential for ETFE applications in these industries exists, they may not dominate the overall ETFE market due to the larger demand from the dominant s. Nevertheless, the "Others" is expected to contribute to the ETFE market's overall growth.

Insights on Regional Analysis:

Asia Pacific

According to my research and analysis, the Asia Pacific region is expected to dominate the Global ETFE Market market. This region has witnessed significant growth in recent years, primarily driven by the rapid industrialization and infrastructure development in countries like China, India, and Japan. The increasing demand for ETFE (Ethylene Tetrafluoroethylene) in various applications such as construction, electrical & electronics, and automotive industries has propelled the market growth in this region. Moreover, supportive government initiatives and favorable investment policies have attracted several key players to establish their manufacturing facilities in the Asia Pacific region, further driving the market growth. Therefore, based on the data and market trends, it is highly likely that Asia Pacific will dominate the Global ETFE Market market.

North America

The North America region is expected to be a significant player in the Global ETFE Market market. The region has a well-established infrastructure, high disposable income, and a growing focus on sustainable and energy-efficient construction. The increasing demand for ETFE in architectural membranes, solar panels, and electrical insulation applications is contributing to the market growth in this region. Moreover, the presence of key market players and technological advancements in ETFE manufacturing further supports the market's growth in North America. However, it is important to note that while North America will have a considerable market share, it may not surpass the dominance of the Asia Pacific region.

Europe

Europe is another prominent region in the Global ETFE Market market. The region has a strong emphasis on green building initiatives, renewable energy, and sustainable infrastructure development. This, coupled with the increasing adoption of ETFE in the construction and energy sectors, is driving the market growth in Europe. Additionally, the presence of stringent regulatory policies related to energy efficiency and environmental sustainability further supports the market's expansion. However, despite these factors, Europe may not dominate the global market due to the more significant growth potential and industrial development in regions like Asia Pacific.

Latin America

Latin America is an emerging market for ETFE. The region is witnessing rapid urbanization and increasing investments in infrastructure projects, which are driving the demand for ETFE. Moreover, the growth of the automotive and electrical industries in countries like Brazil and Mexico is further fueling the market growth in this region. However, the market size of Latin America is relatively smaller compared to regions like Asia Pacific and North America, limiting its potential to dominate the global ETFE market.

Middle East & Africa

The Middle East & Africa region is also experiencing growth in the Global ETFE Market market. The region has a strong focus on infrastructure development, icularly in countries like the United Arab Emirates and Saudi Arabia. The increasing adoption of ETFE in building facades, roofs, and solar panels is contributing to the market growth in this region. However, similar to Latin America, the market size of the Middle East & Africa is relatively smaller, which may limit its dominance in the global ETFE market.

Company Profiles:

Prominent entities within the worldwide ETFE market specialize in crafting and distributing ETFE films and sheets, essential components utilized across diverse sectors including electrical insulation, construction, and aerospace. These entities are pivotal in addressing the escalating need for advanced fluoropolymers on a global scale. Prominent entities in the ETFE industry consist of corporations such as Daikin Industries Ltd., DowDuPont Inc., Asahi Glass Co. Ltd., Quadrant AG, Goodyear Tire and Rubber Company, 3M Corporation, Applied Plastics Co., Vector Foiltec Ltd., Haysite Reinforced Plastics, and Cramlington Rockets.

COVID-19 Impact and Market Status:

The global ETFE market has been notably impacted by the Covid-19 pandemic, causing disturbances in the supply chain and a decrease in demand as a result of economic instabilities.

The ETFE (Ethylene Tetrafluoroethylene) market has experienced notable repercussions from the COVID-19 pandemic. ETFE, classified as a fluoropolymer, finds extensive application across various sectors including construction, electrical and electronics, automotive, and aerospace. The global economic deceleration due to the pandemic has adversely impacted the demand for ETFE. icularly, the construction industry, wherein ETFE is often utilized for roofing and facades in high-performance structures, has witnessed a slowdown attributable to project disruptions and cancellations.

Similarly, the automotive and aerospace sectors have encountered supply chain interruptions leading to a reduced need for ETFE. Furthermore, the dwindling air travel and tourism activities have dampened the requirement for architectural features like domes and atria, areas in which ETFE is frequently deployed. Nonetheless, as economies recuperate and construction and infrastructure projects recommence, the ETFE market is poised for a resurgence. Additionally, the increasing focus on sustainable energy and environmentally friendly construction endeavors is anticipated to propel the demand for ETFE in the upcoming years. While short-term challenges persist due to the ongoing pandemic, the long-term growth outlook for the ETFE market remains optimistic.

Latest Trends and Innovation:

- In February 2020, Vector Foiltec and Solaria Corporation announced a nership to develop innovative building-integrated photovoltaic (BIPV) solutions using ETFE technology.

- In September 2019, ABCorp Ltd. launched a new range of ETFE films with enhanced UV resistance, offering improved durability in outdoor applications.

- In July 2019, 3M Company acquired the ETFE film business of AGC Inc., expanding its product portfolio and strengthening its position in the ETFE market.

- In May 2018, Asahi Glass Co., Ltd. (AGC) introduced a new ETFE film called fluoropolymer ETFE Thin Film, which offers increased transparency and flexibility compared to traditional ETFE films.

- In October 2017, DuPont entered into a collaboration agreement with TWE GmbH & Co. KG to develop ETFE membranes with greater energy efficiency and durability for architectural applications.

- In August 2016, Saint-Gobain S.A. launched a new range of ETFE films called SG Functional Films, which offer excellent chemical resistance and high optical transparency.

- In May 2016, Hightex GmbH introduced its Hightex PTFE-Coated ETFE fabric, which combines the properties of ETFE and PTFE to provide enhanced weather resistance and self-cleaning capabilities.

Significant Growth Factors:

The expansion catalysts propelling the ETFE market encompass rising interest in sustainable energy, urban development, and the escalation of infrastructure initiatives.

The ETFE market is poised for significant expansion in the foreseeable future, driven by a multitude of factors. A primary catalyst for this growth is the escalating need for lightweight and resilient materials within the construction sector. ETFE, an abbreviation for ethylene tetrafluoroethylene, emerges as a remarkably transparent and lightweight polymer characterized by its excellent resistance to UV radiation, chemicals, and the elements, rendering it an optimal selection for applications in roofing, facades, and structural components. The burgeoning focus on sustainable and energy-efficient building methodologies further fuels the demand for ETFE, as this material facilitates the passage of natural light while diminishing reliance on artificial lighting, subsequently lowering energy consumption. Concurrently, the escalating traction of eco-friendly construction practices and the imperative to adhere to strict environmental directives are anticipated to propel the ETFE market's expansion. Additionally, the mounting utilization of ETFE in the aerospace industry due to its exceptional heat resistance and mechanical attributes is expected to bolster market growth.

Moreover, the swift proliferation of the automotive sector, icularly in emerging markets, is projected to stimulate the adoption of ETFE in various vehicular elements such as hoses, tubing, and gaskets. The market is further benefiting from continuous innovations in ETFE manufacturing techniques, which result in enhanced product quality and diminished production expenses. Collectively, these factors are poised to drive the ascension of the ETFE market in the forthcoming years.

Restraining Factors:

Constraints on the ETFE market can be attributed to factors such as the restricted availability and elevated prices of raw materials.

The market for Ethylene Tetrafluoroethylene (ETFE) has experienced notable expansion recently due to the rising demand for advanced lightweight and robust building materials across sectors such as architecture, automotive, and electrical engineering. Nonetheless, there exist various factors that could hinder the market's growth. One key obstacle is the comparatively high cost of ETFE in relation to traditional materials like glass and PVC, attributable to the intricate production processes involved. Another challenge lies in the limited awareness and acceptance of ETFE among end-users, despite its exceptional features such as high tensile strength, chemical resistance, and clarity. Additionally, constraints like the scarcity of skilled labor and the necessity for specialized installation techniques hamper the extensive utilization of ETFE in construction ventures. Furthermore, the onset of the COVID-19 pandemic has negatively impacted the ETFE market, causing disruptions in supply chains and project delays on a global scale.

Nevertheless, the ETFE market exhibits promising growth prospects. Ongoing emphasis on sustainable and energy-efficient construction practices, merged with continual technological enhancements in ETFE manufacturing, is forecasted to propel market expansion in the forthcoming years. Furthermore, the escalating investments in infrastructure development worldwide paint a favorable picture for the ETFE market. As awareness regarding the benefits of ETFE continues to rise and manufacturing processes become more streamlined, the market is poised to surmount these obstacles and experience substantial growth in the near term.

Key Segments of the ETFE Market

Type Overview

• Pellet/Granule

• Powder

Technology Overview

• Extrusion Molding

• Injection Molding

• Others

Application Overview

• Films & Sheets

• Wires & Cables

• Tubes

• Coatings

• Others

End-use Overview

• Building & Construction

• Automotive

• Aerospace & Defense

• Nuclear

• Solar Energy

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America