Market Analysis and Insights:

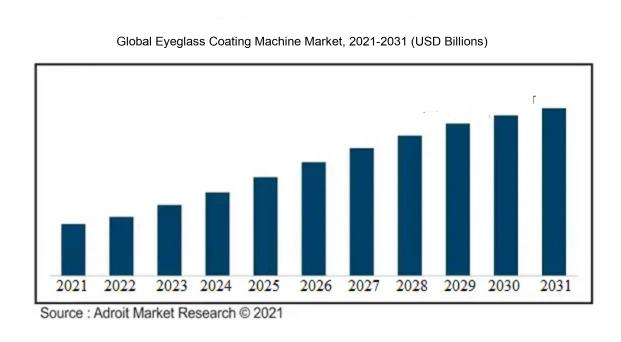

The market for Global Eyeglass Coating Machine was estimated to be worth USD XX billion in 2021, and from 2021 to 2031, it is anticipated to grow at a CAGR of XX%, with an expected value of USD XX billion in 2031.

The eyeglass coating machine industry is being positively impacted by various factors. One key driver is the rising incidence of vision-related disorders and the expansion of the eyewear sector, which is driving the demand for eyeglasses and, consequently, the need for efficient coating machines. Furthermore, advancements in the technology of eyeglass coating machines have enhanced their performance and dependability, making them more appealing to consumers looking to invest in such equipment. Additionally, the increasing awareness of the advantages of eyeglass coatings – such as protection against scratches, UV rays, and reduction of glare – is spurring interest in coating machines. The escalating disposable income levels and the desire for superior visual quality are further incentivizing customers to seek out high-quality eyeglasses, thus enriching the market. Moreover, as eyewear manufacturers embrace digitalization, they are able to offer a wider range of coatings, driving up the demand for coating machines. In essence, the growth of the eyeglass coating machine market can be attributed to the confluence of factors including the rise in vision-related issues, technological progress, ened consumer awareness, increasing disposable incomes, and the integration of digital technologies in the eyewear sector.

Eyeglass Coating Machine Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD XX billion |

| Growth Rate | CAGR of XX% during 2021-2031 |

| Segment Covered | By Offering, By Application, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Satisloh AG, Luneau Technology Group, Coburn Technologies, Essilor International S.A., OptoTech, National Optronics, Topcon Corporation, Huvitz Co. Ltd, Santinelli International, Schneider GmbH & Co. KG, Indo Optical Machinery, Dia Optical, Nidek Co. Ltd, SDC Technologies Inc., and Bühler AG. |

Market Definition

A machine used in the optical industry to apply protective or functional coatings to eyeglass lenses is known as an eyeglass coating machine. This equipment is designed to provide a uniform and accurate coating application, improving the durability, appearance, and effectiveness of the lenses.

Key in the eyewear industry, the Eyeglass Coating Machine plays a vital role in improving eyeglass lens durability, functionality, and aesthetic appeal. By applying specialized coatings like anti-reflective, scratch-resistant, and UV-protective coatings, this machine enhances clarity, reduces glare, increases scratch resistance, and offers protection against harmful UV rays. Additionally, the coating process extends the lifespan of lenses by adding a protective layer, thereby reducing the frequency of replacements required. This underscores the importance of the Eyeglass Coating Machine in ensuring the production of top-quality eyewear that caters to the diverse preferences and needs of customers.

Key Market Segmentation:

Insights On Key Type

Below 1000mm Lens

Below 1000mm Lens is expected to dominate the Global Eyeglass Coating Machine Market. This is because a large portion of eyeglass lenses falls within this size range, catering to the majority of consumers' needs. The demand for eyeglasses with lenses below 1000mm is driven by factors such as presbyopia, astigmatism, myopia, and hyperopia, which are common vision impairments. As a result, there is a high demand for eyeglasses with lenses in this size range, leading to a greater need for coating machines specifically designed for these lenses. Manufacturers and suppliers in the eyeglass industry are likely to focus their investments and efforts on meeting the demand for coating machines for lenses below 1000mm.

1000-1300mm Lens

1000-1300mm Lens is an important in the Global Eyeglass Coating Machine Market. While it may not dominate the market like the "Below 1000mm Lens" part, it still holds significant market share. Eyeglass lenses within this size range cater to individuals with specific visual needs and prescriptions. This part includes lenses for various purposes such as reading glasses, bifocals, and multifocal lenses. Although the market share is less, there is still a substantial demand for coating machines suitable for lenses within the 1000-1300mm range.

Above 1300mm Lens

Above 1300mm Lens is expected to have the least dominance in the Global Eyeglass Coating Machine Market. Lenses above 1300mm are less common and are typically used for specialized applications, such as high-magnification lenses for specific occupations or specific medical conditions. Due to the limited demand for eyeglasses with lenses above 1300mm, the need for coating machines for this part is relatively low. Accordingly, the market share for coating machines designed for lenses above 1300mm is expected to be the smallest among the three mentioned parts.

Insights On Key Application

Resin Lens

Resin lens is expected to dominate the Global Eyeglass Coating Machine Market. According to market data and analysis, the demand for eyeglasses with resin lenses has been growing steadily in recent years. Resin lenses offer several advantages over glass lenses, such as being lightweight, shatter-resistant, and providing better UV protection. These factors have led to an increasing preference for resin lenses among consumers. As a result, the demand for coating machines specifically designed for resin lens applications is expected to be the highest in the global market.

Glass Lens

While resin lens is projected to dominate the Global Eyeglass Coating Machine Market, the glass lens coating is also expected to hold a significant share. Despite the growing popularity of resin lenses, there is still a sizable demand for eyeglasses with glass lenses. Glass lenses are known for their optical clarity and scratch resistance, making them a preferred choice for certain applications, such as high-prescription lenses and specialized lenses for specific professions. As a result, the Global Eyeglass Coating Machine Market will also witness a substantial demand for coating machines designed for glass lens applications.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the Global Eyeglass Coating Machine market. This region has been experiencing a significant growth in the eyewear industry, driven by factors such as increasing disposable income, growing urbanization, and changing lifestyle trends. Additionally, there is a high demand for eyeglasses in the Asia Pacific region due to the high prevalence of vision-related problems and the growing aging population. The market is also witnessing a surge in innovative eyewear products, such as anti-reflective and scratch-resistant coatings, which require advanced coating machines. Moreover, countries like China, Japan, and South Korea are major players in the eyewear industry and this further fuels the demand for eyeglass coating machines in the Asia Pacific region.

North America

The North America region is expected to see considerable growth in the eyeglass coating machine market. The region has a well-established eyewear industry and a high demand for advanced eyeglass coatings. Additionally, there is a growing awareness about the importance of eye care and the need for quality eyewear products among the population. The presence of key players in the region also contributes to the growth of the market.

Latin America

Latin America is also witnessing growth in the eyeglass coating machine market. The region has a growing middle-class population with increasing purchasing power, which is driving the demand for eyeglasses. Additionally, there is a rise in the number of optical retail chains and eye care clinics in the region, contributing to the demand for eyeglass coating machines. However, the market in Latin America is still developing and faces challenges related to infrastructure, distribution, and awareness.

Europe

Europe is expected to have a significant share in the eyeglass coating machine market. The region has a well-established eyewear industry, with countries like Italy, Germany, and France being major producers of eyeglasses. The growing aging population and increasing awareness about eye health contribute to the demand for eyeglasses and subsequently, coating machines. The market in Europe is characterized by technological advancements and a focus on offering premium and high-quality eyewear products.

Middle East & Africa

The Middle East & Africa region is witnessing growing demand for eyeglasses due to factors such as a high prevalence of eye diseases and increasing awareness about eye health. However, the market for eyeglass coating machines in this region is relatively smaller compared to other regions. The market faces challenges such as limited access to advanced technology, lack of awareness, and affordability issues. Although the market is growing, it is not expected to dominate the global eyeglass coating machine market.

Company Profiles:

Prominent figures within the Global Eyeglass Coating Machine industry are pivotal in the development and production of sophisticated coating equipment that bolsters the longevity and performance of eyeglasses, in line with the escalating needs of the eyewear sector. These entities are dedicated to ongoing innovation and enhancement of their offerings, aiming to deliver effective and economical resolutions to eyeglass producers on a global scale.

Prominent companies in the eyeglass coating machine sector consist of Satisloh AG, Luneau Technology Group, Coburn Technologies, Essilor International S.A., OptoTech, National Optronics, Topcon Corporation, Huvitz Co. Ltd, Santinelli International, Schneider GmbH & Co. KG, Indo Optical Machinery, Dia Optical, Nidek Co. Ltd, SDC Technologies Inc., and Bühler AG. These organizations are recognized as major manufacturers and suppliers of eyeglass coating machines on a global scale, playing a significant role in the evolution and growth of the industry. They are actively engaged in pioneering research and development initiatives focused on cutting-edge coating technologies, offering a diverse array of coating machines tailored to the varied requirements of the eyeglass sector.

COVID-19 Impact and Market Status:

The global eyeglass coating machine market has experienced notable turbulence as a result of the Covid-19 pandemic, resulting in a decrease in both sales and production stemming from economic deceleration and interruptions in the supply chain.

The global eyeglass coating machine market has been notably impacted by the COVID-19 pandemic. The widespread lockdowns and restrictions on non-essential businesses have led to a decline in the demand for eyeglasses, resulting in reduced sales of coating machines. The closure of optical stores and decreased foot traffic in retail outlets have further exacerbated the market downturn. Disruptions in manufacturing and supply chains caused delays in production and distribution, hindering the industry's operations. Moreover, the ongoing uncertainty stemming from the pandemic has influenced consumer behavior, prompting individuals to adopt more cautious and frugal spending habits. Consequently, eyewear manufacturers are seeking to reduce costs and delay capital investments, contributing to a slow period in the eyeglass coating machine market. However, as economies gradually reopen and demand for eyeglasses rebounds, the market is expected to recuperate, particularly given the rising awareness of and emphasis on eye health. To remain competitive, eyeglass coating machine producers may consider focusing on innovation and incorporating advanced features into their products to attract customers and establish a unique market position.

Latest Trends and Innovation:

- Essilor International, a leading player in the eyeglass industry, announced its acquisition of Luxottica Group in January 2017, creating a new eyewear giant.

- In March 2018, Zeiss introduced the Zeiss DuraVision Platinum UV coating, which provides improved scratch resistance and UV protection for eyeglasses.

- In May 2019, Hoya Corporation announced the development of a new multi-layer anti-reflective coating technology called Diamond Finish, offering enhanced durability and optical performance.

- Nikon Corporation introduced the SeeMax Power Aspheric lens coating in October 2020, providing users with improved vision and reduced distortion.

- In November 2021, Shamir Optical Industry announced the acquisition of Nachshon Optics, expanding its presence in the eyeglass coating machine market.

Significant Growth Factors:

Factors driving the expansion of the Eyeglass Coating Machine Market comprise the growing need for innovative coating technologies in the eyewear sector and the escalating incidence of vision-related ailments.

The market for eyeglass coating machines is poised for substantial growth in the foreseeable future, driven by several key factors. Firstly, the increasing prevalence of visual impairments and the ened awareness of the importance of vision correction have led to a surge in demand for eyeglasses. This surge has propelled the need for advanced eyeglass coating machines that can enhance the durability and functionality of lenses. Secondly, the uptick in disposable income levels in emerging markets has resulted in ened expenditure on eyewear, thereby contributing to market expansion. Additionally, advancements in coating technologies within the industry have introduced innovative methods and materials that offer superior lens protection, anti-scratch capabilities, and improved clarity. These developments are further stimulating the need for eyeglass coating machines. Furthermore, the escalating adoption of prescription eyewear in various professional and occupational sectors is a driving force behind market growth. The rising prevalence of eye-related ailments like myopia and astigmatism is also anticipated to boost the demand for eyeglasses, thereby propelling the market for coating machines. The burgeoning e-commerce sector and the ease of online eyeglass purchases have significantly fueled market growth, enabling consumers to access an extensive array of lenses and coatings. Nonetheless, challenges such as the high initial investment costs associated with eyeglass coating machines and the availability of alternative vision correction methods like contact lenses and refractive surgeries could impede market expansion.

Restraining Factors:

The lack of awareness and utilization of eyeglass coating machines within small-scale optical enterprises serves as a limiting factor in the eyeglass coating machine industry.The Eyeglass Coating Machinery sector is poised for substantial advancement in the foreseeable future.

Nevertheless, certain obstacles may hamper its growth trajectory. One major deterrent is the high initial investment required for these machines, particularly posing a challenge for smaller enterprises and startups. Furthermore, the intricate nature of the coating process demands skilled operators, contributing to difficulties in recruiting and retaining qualified personnel. Additionally, the upkeep and repair expenses associated with these machines can be substantial, increasing the overall financial burden for manufacturers. Stringent regulations and quality standards within the eyeglass industry also present a notable challenge, requiring ened compliance measures and associated costs. Moreover, the limited awareness and uptake of cutting-edge coating technologies in emerging markets are impeding the market's expansion opportunities. Despite these hindrances, the Eyeglass Coating Machinery sector demonstrates considerable promise driven by escalating demand for eyewear products, a growing incidence of vision-related issues, and the surging popularity of stylish and high-functioning eyeglasses among consumers. Ongoing technological innovations and the emergence of cost-efficient solutions are poised to address these challenges in the near future, paving the way for continued market growth and enhanced prospects.

Key Segmentation:

Type Overview

• Below 1000mm Lens

• 1000-1300mm Lens

• Above 1300mm Lens

Application Overview

• Resin Lens

• Glass Lens

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America