Market Analysis and Insights:

The market for Formaldehyde was estimated to be worth USD 8.32 billion in 2021, and from 2022 to 2030, it is anticipated to grow at a CAGR of 5.92%, with an expected value of USD 13.66 billion in 2030.

.jpg

)

The formaldehyde market experiences various driving forces that propel its growth. The construction sector is a key influencer due to the extensive use of formaldehyde in producing adhesives, resins, and foams essential for activities like furniture manufacturing and insulation. Similarly, the automotive industry significantly impacts the market as formaldehyde is employed in manufacturing automotive components like brake shoes, fuel systems, and interior trims, benefiting from global automobile production growth and technological advancements. Furthermore, the healthcare industry is a major player in the demand for formaldehyde in disinfectants, sterilization equipment, and preservatives for medical and pharmaceutical products. Other contributing factors include the textiles industry's rising need for formaldehyde in textile finishing and its applications in plastics, resins, and coatings production. The market is further boosted by population growth, urbanization, and industrial development in emerging economies. Nevertheless, concerns about sustainability and stringent regulations on formaldehyde emissions could impede the market's progress.

Formaldehyde Market Scope :

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2030 |

| Study Period | 2018-2030 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2030 | USD 13.66 billion |

| Growth Rate | CAGR of 5.92% during 2022-2030 |

| Segment Covered | Fibers, Solvents, Plasticizers, Drying Agents, Resins, Other Chemical Intermediaries |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | BASF SE, Celanese Corporation, Huntsman International LLC, Dynea AS, Momentive Performance Materials Holdings LLC, Georgia-Pacific LLC, Foremark Performance Chemicals (Jiangsu Yangnong Chemical Group Co., Ltd.), Perstorp Holding AB, and Jinan Shengquan Group Share Holding Co., Ltd. |

Market Definition

Formaldehyde is an odorless gas that is frequently utilized as a preservative and disinfectant due to its colorless nature. It is a common ingredient in a variety of household goods and construction materials, potentially presenting health hazards at elevated exposure concentrations.

Formaldehyde, a significant chemical compound with diverse applications across various sectors, serves as a vital preservative and disinfectant in fields such as medicine and healthcare. It effectively prevents the growth of microorganisms, a critical function in preserving biological specimens and averting microbial contamination. Furthermore, formaldehyde is integral in the manufacturing of resins and adhesives, being utilized in industries like construction and production. These resins play a pivotal role in creating plywood, furniture, laminate flooring, and assorted composite materials. In the textile realm, formaldehyde acts as a fabric treatment chemical, enhancing fabrics' resistance to wrinkles and shrinkage. Additionally, it is a key component in the development of plastics, paints, and coatings, improving their durability and performance. Nonetheless, it is important to acknowledge that formaldehyde exposure carries health risks, necessitating careful handling of the chemical and adherence to safety protocols to mitigate potential harm.

Key Market Segmentation:

Insights On Key Derivative

UF Resins

UF Resins dominate the global formaldehyde market due to their wide range of applications, including particleboard, plywood, and medium-density fiberboard (MDF) production. UF resins offer good bonding strength, water resistance, and low production costs, making them the preferred choice in various industries.

Phenol Formaldehyde (PF) Resins

PF resins are widely used in the production of molded products, such as household appliances, automotive components, and electrical insulation materials. These resins provide excellent heat resistance, mechanical strength, and dimensional stability, making them suitable for applications where high-performance materials are required.

MF Resins

MF resins find significant usage in the textile industry for fabric wrinkle resistance, easy care finishes, and durable press treatments. They are also used in the production of molded products, adhesives, and laminates. MF resins offer high reactivity and excellent compatibility with various substrates.

Polyacetal Resins

Polyacetal resins, commonly known as acetal resins, are widely used in automotive, electrical, and consumer goods industries. They exhibit superior mechanical properties, low friction, and good dimensional stability, making them suitable for applications such as gears, bearings, and electrical connectors.

1,4-butanediol

1,4-butanediol is primarily used as a raw material in the production of tetrahydrofuran (THF) and polybutylene terephthalate (PBT). THF finds application as a solvent and raw material for the production of various chemicals, while PBT is used in the automotive and electrical industries for manufacturing components such as connectors, switches, and circuit breakers.

Pentaerythritol

Pentaerythritol is mainly utilized in the production of alkyd resins, which find extensive usage in coatings, paints, varnishes, and adhesives. The growing demand for these applications drives the demand for pentaerythritol, as alkyd resins offer exceptional hardness, glossy finish, and weather resistance.

Methylenebis

Methylenebis is an important reagent used in various industries, including chemical, pharmaceutical, and textile. It finds application as an intermediate in the production of dyes, pigments, pharmaceuticals, and other organic compounds. The demand for methylenebis is driven by the flourishing chemical and pharmaceutical sectors.

Insights On Key Application

Resins

The dominating part in the Global Formaldehyde market is Resins. Resins are widely used in various industries such as construction, automotive, and furniture manufacturing for their adhesive properties and ability to enhance durability. The growing demand for resins in these industries, coupled with the increasing construction activities globally, is expected to drive the growth of the formaldehyde market in the resin application.

Fibers:

Fibers are one of the parts in the Global Formaldehyde market. Fibers derived from formaldehyde are used in the production of textiles, especially in the textile industry. Although the demand for formaldehyde-based fibers is significant, it is not expected to dominate the market due to the increasing popularity of synthetic fibers and alternative materials.

Solvents:

Solvents are another part in the Global Formaldehyde market. Formaldehyde-based solvents find their applications in various industries such as paints, coatings, and pharmaceuticals. However, the dominance of other solvents in these industries is expected to limit the market growth of formaldehyde-based solvents.

Plasticizers:

Plasticizers, which are used to increase the flexibility and durability of plastics, are also a part in the Global Formaldehyde market. The demand for formaldehyde-based plasticizers is expected to grow, especially in the construction and automotive industries. However, the dominance of alternative plasticizers and increasing environmental concerns may restrict their market dominance.

Drying Agents:

Drying agents, also known as desiccants, are used to remove moisture and humidity from certain products and environments. While formaldehyde-based drying agents have some applications, they are not expected to have significant dominance in the Global Formaldehyde market due to the availability of alternative drying agents with better performance.

Insights On Key End-use

Consumer Goods

The consumer goods part is expected to dominate the global formaldehyde market. The demand for formaldehyde in the consumer goods industry is driven by its wide range of applications, including in the production of furniture, textiles, plastics, and personal care products. Formaldehyde is used as a binding agent, preservative, and disinfectant in these various consumer goods. Additionally, the rising consumer awareness towards sustainable and eco-friendly products has led to the increased use of formaldehyde-free alternatives in the consumer goods sector.

Healthcare

The healthcare part of the global formaldehyde market is characterized by the use of formaldehyde in medical equipment sterilization, pharmaceutical production, and laboratory testing. Formaldehyde has excellent disinfectant properties and is widely utilized for the sterilization of medical devices and instruments. It is also used in the production of various pharmaceutical products such as vaccines, drugs, and diagnostic reagents. The increasing demand for healthcare services and the growing importance of maintaining hygiene and cleanliness in healthcare facilities contribute to the demand for formaldehyde in this sector.

Automotive

In the automotive industry, formaldehyde finds application in the production of automotive interiors, including upholstery, carpets, and seat covers. Formaldehyde-based resins are commonly used in the manufacturing of these products, as they offer durability and fire resistance. The automotive part of the global formaldehyde market is driven by the growing automotive production and the constant advancements in automotive interior design.

Construction

Formaldehyde plays a significant role in the construction industry, primarily in the production of adhesives, resins, and composite materials. It is widely used as a binding agent in the manufacture of plywood, particleboard, and medium-density fiberboard (MDF) used in the construction of furniture, cabinets, flooring, and other building materials. The construction part of the global formaldehyde market benefits from the construction activities across residential, commercial, and infrastructure sectors worldwide.

Insights on Regional Analysis:

Asia Pacific

The Asia Pacific region is expected to dominate the global formaldehyde market. This dominance can be attributed to the growing population, rapid industrialization, and increasing construction activities in countries such as China and India. Moreover, the region is witnessing a rise in demand for formaldehyde-based resins from various end-use industries, including automotive, furniture, and textiles. With the presence of major manufacturers and a favorable regulatory environment, the Asia Pacific region is set to maintain its dominance in the global formaldehyde market.

North America

North America is another significant market for formaldehyde, characterized by stringent regulations and advanced manufacturing processes. The region's dominance is driven by various end-use industries, including healthcare, automotive, and construction. Additionally, the increasing demand for formaldehyde-based resins in the wood products sector further contributes to the market growth. The presence of key players and a focus on sustainable manufacturing practices also aid the formaldehyde market in North America.

Europe

Despite stringent regulations surrounding formaldehyde usage, the formaldehyde market in Europe is expected to witness steady growth. The region's dominance is primarily driven by the increasing demand from sectors such as automotive, construction, and furniture. The European Union's strict emission standards and sustainability initiatives promote the use of formaldehyde-based resins, further propelling market growth. With ongoing research and development activities, Europe is poised to remain a key player in the global formaldehyde market.

Latin America

Latin America is anticipated to witness moderate growth in the formaldehyde market. The region's construction industry plays a vital role in driving market demand for formaldehyde-based resins and adhesives. Additionally, the growing automotive and furniture industries contribute to the market growth in Latin America. However, factors such as fluctuations in raw material prices and environmental concerns regarding formaldehyde emissions limit the market's full potential in the region.

Middle East & Africa

The Middle East & Africa region is projected to experience gradual growth in the formaldehyde market. The region's construction industry, driven by significant infrastructural development projects, creates a demand for formaldehyde-based resins and adhesives. However, factors such as limited manufacturing capabilities and the volatile political and economic landscape in certain countries pose challenges for market growth. Nonetheless, ongoing investments in various industries and the implementation of sustainability measures present opportunities for the formaldehyde market in the Middle East & Africa.

Company Profiles:

Prominent entities within the international formaldehyde sector, including BASF SE and Huntsman International LLC, play a pivotal role in the production and distribution of formaldehyde-derived goods to a wide range of industry verticals. Their proactive engagement significantly fuels market advancement, underpinned by their commitment to innovation, product excellence, and the fulfillment of customer demands on a global scale.

Prominent participants in the formaldehyde industry comprise BASF SE, Celanese Corporation, Huntsman International LLC, Dynea AS, Momentive Performance Materials Holdings LLC, Georgia-Pacific LLC, Foremark Performance Chemicals (Jiangsu Yangnong Chemical Group Co., Ltd.), Perstorp Holding AB, and Jinan Shengquan Group Share Holding Co., Ltd.

These entities actively engage in the manufacturing, distribution, and promotion of formaldehyde and its associated products. Through their diverse formaldehyde-derived product portfolios, these firms have established robust market positions across sectors including construction, automotive, textiles, and healthcare. They continuously endeavor to innovate and diversify their product ranges to meet escalating consumer requirements, all while adhering to stringent regulations and upholding sustainable operational practices.

COVID-19 Impact and Market Status:

The global formaldehyde market has been adversely affected by the Covid-19 pandemic, largely as a result of supply chain disruptions and a decline in demand from various industries.

The formaldehyde market has been significantly affected by the COVID-19 pandemic, presenting challenges as well as opportunities. Stringent lockdown measures and supply chain disruptions have caused a decrease in the consumption of formaldehyde-based products in sectors such as construction, automotive, and furniture due to reduced demand. This has impacted the production of formaldehyde resin adhesives and wood-based panel resins, as construction activities and manufacturing processes have slowed. Moreover, the increased time spent indoors has led to a slowdown in furniture demand and home renovation projects. However, the pandemic has also opened up new avenues for the formaldehyde market. With a ened focus on hygiene and disinfection, there has been a rise in the demand for sanitizers and cleaning products containing formaldehyde solutions. Furthermore, the healthcare industry has seen an increase in the production of personal protective equipment and medical devices, further boosting the demand for formaldehyde-based materials. As the global situation improves, the formaldehyde market is expected to recover, with an emphasis on sustainable and environmentally-friendly solutions to align with evolving consumer preferences and stricter regulations concerning formaldehyde emissions.

Latest Trends and Innovation:

- In August 2020, BASF SE, a leading chemical company, announced the acquisition of Solvay's integrated polyamide business. This strategic move aimed at strengthening BASF's position in the formaldehyde market and expanding its product portfolio.

- In September 2019, Hexion Inc., a global leader in thermoset resins, launched its latest formaldehyde-based resin technology called EPI-REZ Resin 7720-W-52. This innovation offers improved water resistance and adhesion in coatings and adhesives applications.

- In July 2018, Dynea AS, a Norwegian formaldehyde specialty company, entered into a merger agreement with Hexion Inc. The merger aimed at combining the strengths of both companies in formaldehyde-based solutions and expanding their global reach.

- In March 2017, Momentive Specialty Chemicals Inc., a global leader in silicones and advanced materials, completed the acquisition of Hexion Inc., leading to the formation of a new company, Momentive Performance Materials Holdings LLC. This merger marked a significant milestone in the formaldehyde market, enabling the combined entity to offer a broader range of innovative solutions.

- In January 2016, Georgia-Pacific LLC, a global manufacturer of paper products, announced the expansion of its formaldehyde resin plant in Alabama. This expansion aimed to meet the growing demand for formaldehyde-based resins in various industries and strengthen Georgia-Pacific's position in the market.

Significant Growth Factors:

The expansion of the formaldehyde industry is propelled by rising requirements from the construction, automotive, and textile sectors owing to its multifaceted uses and economic viability.

The formaldehyde market is on track for substantial expansion in the foreseeable future, driven by various significant factors. Primarily, the ened demand for formaldehyde-infused resins and adhesives across sectors like construction, automotive, and furniture is a primary driver of this growth trajectory. These solutions find widespread utility in the fabrication of plywood, laminated veneer lumber, and particleboard, which are crucial materials in the realm of construction and interior design. Additionally, the expanding utilization of formaldehyde in the synthesis of fundamental chemicals like plastics, paints, and coatings is further pushing the market forward. Furthermore, the surging adoption of formaldehyde for disinfection and preservation purposes in the healthcare and beauty sectors is also playing a role in the market's expansion. Formaldehyde-based products are employed extensively in hospitals, laboratories, and pharmaceutical settings for sterilization requirements. Moreover, the increasing acknowledgment of the advantages associated with using formaldehyde-based items in personal care and beauty products, including nail varnishes, shampoos, and creams, is fostering market growth. Lastly, the ongoing efforts in research and development aimed at refining production processes and enhancing product quality are expected to propel market growth in the upcoming years.

Collectively, the formaldehyde market stands to experience remarkable advancement owing to its diverse applications across multiple industries and the growing demand for formaldehyde-infused products.

Restraining Factors:

Limiting aspects impacting the Formaldehyde Market involve concerns about its adverse effects on human health and the strict regulatory framework governing its application.

The formaldehyde industry encounters various challenges that hinder its progress and development. One of the primary issues is the stringent regulations and environmental concerns associated with formaldehyde emissions. Governments worldwide have implemented strict guidelines and emission standards to regulate the discharge of formaldehyde into the environment due to its adverse effects on human health and the ecosystem. Consequently, formaldehyde producers face increasing pressure to adopt cleaner production techniques and invest in advanced technologies to minimize emissions.

Moreover, the formaldehyde market is significantly affected by fluctuations in raw material prices, primarily methanol, which is the primary source of formaldehyde production. Variations in methanol prices directly influence the overall production costs of formaldehyde, thereby impacting the pricing of formaldehyde-based products in the market.

Additionally, the availability of alternative products and substitutes, such as bio-based chemicals, poses a challenge to the formaldehyde industry as consumers are increasingly seeking environmentally friendly alternatives due to health and safety concerns. These substitutes serve as viable options and reduce the demand for formaldehyde-based solutions.

Notwithstanding these challenges, there are positive aspects within the formaldehyde market. The rising awareness regarding the harmful effects of formaldehyde has led to a growing demand for low-emission and formaldehyde-free products, particularly in industries like construction, automotive, and healthcare. This presents an opportunity for formaldehyde producers to innovate and develop products that cater to the market's need for safer and sustainable alternatives.

Furthermore, significant advancements in research and development have been made in formaldehyde production, leading to the introduction of alternative methods and technologies that decrease emissions and enhance the overall sustainability of the formaldehyde market.

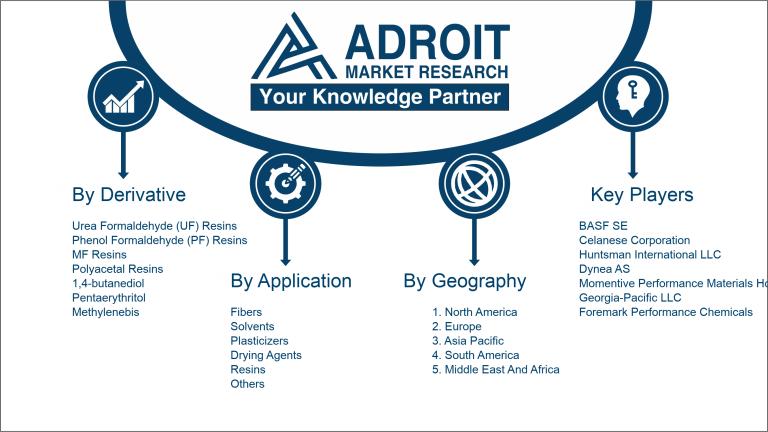

Key Segments of the Formaldehyde Market

Formaldehyde Derivative Overview

- Urea Formaldehyde (UF) Resins

- Phenol Formaldehyde (PF) Resins

- MF Resins

- Polyacetal Resins

- 1,4-butanediol

- Pentaerythritol

- Methylenebis

Application Overview

- Fibers

- Solvents

- Plasticizers

- Drying Agents

- Resins

- Other Chemical Intermediaries

End-Use Overview

- Healthcare

- Consumer Goods

- Automotive

- Construction

- Others

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America