Friction Welding Machines Market Analysis and Insights:

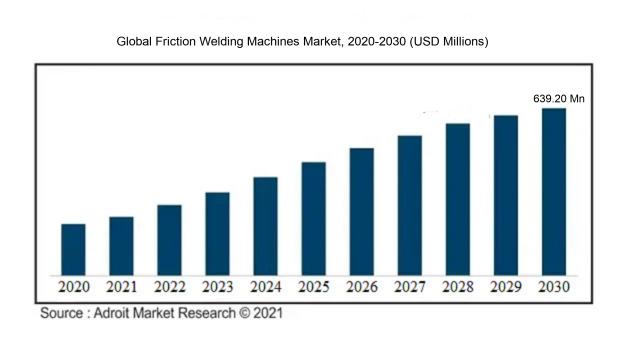

The market for Global Friction Welding Machines was estimated to be worth USD 497.96 million in 2024, and from 2024 to 2030, it is anticipated to grow at a CAGR of 3.02%, with an expected value of USD 639.20 million in 2030.

The global market for friction welding machines is experiencing growth due to various factors. One key driver is the rising need for lightweight and durable materials in industries like automotive, aerospace, and construction, leading to increased adoption of friction welding machines. These machines provide stronger and more reliable joints compared to traditional welding methods. Another factor is the focus on reducing manufacturing costs and improving productivity, which is fueling the use of friction welding machines. They offer faster welding speeds, reduced post-welding processes, and lower energy consumption, resulting in cost savings for manufacturers. Moreover, the industry's shift towards sustainable practices and eco-friendly welding processes is also propelling market growth. Friction welding is considered environmentally friendly as it doesn't involve consumables or emissions. Additionally, advancements in friction welding technology, including automation and robotics integration, are enhancing efficiency and precision, further boosting market expansion. In summary, driven by the demand for superior welding performance, cost-effectiveness, and sustainability, the friction welding machines market is poised for significant growth in the foreseeable future.

Friction Welding Machines Market Definition

Friction welders are mechanical instruments which employ rotational force and heat generated through friction to unite two materials without the requirement of supplementary substances or external heat suppliers. Widely applied in industrial operations, they facilitate the formation of durable and cohesive connections among diverse metal elements.

Friction welders are essential pieces of equipment used in a variety of industries to securely and efficiently join two or more materials. By utilizing frictional heat and force, these machines create strong bonds between materials without the need for additional substances like adhesives or fasteners. Their significance lies in the ability to produce durable and reliable welds, ultimately enhancing the integrity and longevity of the final product. In addition to reducing production time and improving product quality, they also offer cost-effectiveness. With the capability to weld a wide range of materials including metals and plastics, friction welders are versatile tools that play a crucial role in ensuring the strength and stability of products in different sectors of manufacturing.

Friction Welding Machines Market Segmental Analysis:

Insights On Type

Linear Friction Welding

Linear Friction Welding is expected to dominate the Global Friction Welding Machines Market. Linear Friction Welding offers various advantages such as high productivity, precision, and the ability to join dissimilar materials. These features make it suitable for various applications including automotive, aerospace, and industrial sectors. The demand for lightweight and fuel-efficient vehicles in the automotive industry is driving the growth of Linear Friction Welding. Additionally, the aerospace industry's need for strong and durable joints further contributes to the dominance of Linear Friction Welding in the market.

Rotary Friction Welding

Rotary Friction Welding, although not expected to dominate the market, still holds significant relevance in certain industries. This process is often used for joining cylindrical parts in industries such as automotive, oil and gas, and construction. The ability of Rotary Friction Welding to achieve strong and homogeneous joints in a short time makes it suitable for these applications. However, due to specific design requirements and limitations, its usage might be more limited compared to Linear Friction Welding.

Stir Friction Welding

Stir Friction Welding is another sector that might not dominate the Global Friction Welding Machines Market but it still has its uses. Stir Friction Welding is primarily employed for joining non-ferrous materials such as aluminum and copper. This process is particularly popular in industries like automotive, aerospace, and marine, where lightweight materials and superior mechanical properties are crucial. Stir Friction Welding offers high-quality joints with reduced defects, making it an attractive option for specific applications within these industries.

Insights On Application

Automotive

The Automotive application is expected to dominate the Global Friction Welding Machines market. The automotive industry is one of the largest users of friction welding technology due to its ability to join dissimilar materials, such as aluminum and steel, which are frequently used in automotive manufacturing. Friction welding machines enable efficient and robust joining of components, resulting in high-quality and reliable automotive parts. With the growing demand for lightweight and fuel-efficient vehicles, the automotive industry is continuously exploring innovative technologies like friction welding, making it the dominating part in the Global Friction Welding Machines market.

Aerospace and Defence

The Aerospace and Defence application is another significant player of the Global Friction Welding Machines market. In the aerospace and defence industry, the demand for strong and reliable joints for critical components is crucial. Friction welding offers high welding strength, improved fatigue resistance, and reduced distortion, making it an ideal choice for aerospace and defence applications. As the aerospace and defence industry continues to grow and invest in advanced manufacturing technologies, the demand for friction welding machines is expected to increase.

Shipbuilding

The Shipbuilding application also holds substantial potential in the Global Friction Welding Machines market. The shipbuilding industry requires strong and durable welds for various components, including hulls, propellers, and piping systems. Friction welding offers several advantages in shipbuilding, such as excellent weld quality, enhanced productivity, and reduced material waste. With the growth in global marine transportation and the need for efficient and reliable ships, the demand for friction welding machines in the shipbuilding industry is expected to rise.

General Machine Manufacturing

The General Machine Manufacturing application is another important player of the Global Friction Welding Machines market. This category includes various industries involved in the manufacturing of machinery and equipment for different purposes. Friction welding machines find applications in the production of components for industrial machinery, agricultural equipment, construction machinery, and many other sectors. The ability of friction welding to join dissimilar materials and its cost-effectiveness makes it attractive for manufacturers in the general machine manufacturing sector.

Others

The Others category encompasses various industries that do not fall under the categories mentioned above. This could include niche applications or emerging industries that are increasingly adopting friction welding machines. While the demand in this part may be relatively smaller compared to the dominant s, it still represents potential market opportunities for friction welding machine manufacturers. Examples of industries in the "Others" part could be energy, medical, or consumer goods, where friction welding offers unique advantages for specific applications.

Global Friction Welding Machines Market Regional Insights:

Europe

Europe is expected to dominate the Global Friction Welding Machines market. This can be attributed to several factors. Firstly, Europe has a strong manufacturing industry, which necessitates the use of friction welding machines for joining various components and producing high-quality products. The automotive industry in Europe, in particular, relies heavily on friction welding machines for the production of lightweight and fuel-efficient vehicles. Additionally, Europe is home to several prominent manufacturers of friction welding machines, providing a competitive advantage in terms of product quality, innovation, and customer support. Furthermore, Europe has a well-established infrastructure and favorable government initiatives supporting the adoption of advanced technologies, including friction welding machines. Overall, these factors make Europe the dominating region in the Global Friction Welding Machines market.

North America

North America, although not the dominating region, holds a significant share in the Global Friction Welding Machines market. The region has a strong industrial base, particularly in sectors such as aerospace, automotive, and energy, where friction welding machines play a vital role. The aerospace industry, in particular, utilizes friction welding machines for joining critical components, ensuring structural integrity and safety. Moreover, the automotive industry in North America is focused on lightweighting vehicles and improving fuel efficiency, which further fuels the demand for friction welding machines. Additionally, North America is known for its advanced research and development capabilities, driving technological advancements in the friction welding machines market. Although Europe dominates the market, North America remains a key player in this sector.

Asia Pacific

The Asia Pacific region is witnessing significant growth in the Global Friction Welding Machines market. The region's thriving manufacturing industry, particularly in countries like China, Japan, South Korea, and India, is driving the demand for friction welding machines. These countries have well-established automotive and aerospace industries, which are major end-users of friction welding machines. Additionally, the rising investments in infrastructure development, increasing foreign direct investments, and government initiatives to promote manufacturing capabilities in the region are further boosting the market growth. The Asia Pacific region offers cost advantages in terms of labor and production, attracting key market players to establish their manufacturing facilities. Although Europe dominates the market, the Asia Pacific region is rapidly growing and is expected to become a significant contender in the Global Friction Welding Machines market.

Latin America

Latin America holds a smaller share in the Global Friction Welding Machines market compared to Europe. The region's manufacturing industry is still developing and has not reached the same level of maturity as other regions. However, there is considerable potential for growth in sectors such as automotive, aerospace, and infrastructure development, which can drive the demand for friction welding machines in the future. The increasing demand for lightweight and fuel-efficient vehicles, along with growing investments in infrastructure projects, will likely create opportunities for friction welding machine manufacturers in Latin America. Although currently not dominating the market, Latin America has the potential to contribute significantly to the Global Friction Welding Machines market in the coming years.

Middle East & Africa

The Middle East & Africa region has a relatively smaller share in the Global Friction Welding Machines market compared to Europe. The region's manufacturing industry is still evolving, primarily focused on sectors such as oil and gas, automotive, and construction. While the oil and gas sector drives the demand for friction welding machines in the region, other industries are gradually recognizing the benefits of friction welding and its applications. The Middle East & Africa region, particularly countries like Saudi Arabia, UAE, and South Africa, has witnessed infrastructure development projects that drive the demand for friction welding machines. Although currently not dominating the market, the Middle East & Africa region holds potential for growth in the Global Friction Welding Machines market.

Global Friction Welding Machines Market Competitive Landscape:

Prominent entities within the international Friction Welding Machinery sector are pivotal in propelling technological progress and originality in the field, alongside furnishing top-tier machinery and resolutions to cater to the escalating requisites for friction welding operations globally. As per trustworthy references, elite enterprises like Branson Ultrasonics (Emerson Electric Co.), KUKA AG, NITTO SEIKI CO., LTD., and Thompson Friction Welding Ltd. are instrumental in the market by providing diverse friction welding machines, ensuring exceptional efficiency, and broadening their worldwide footprint via astute collaborations and procurements.

Prominent companies in the Friction Welding Machines Market are Branson Ultrasonics Corporation, EMAG, Composite Automation LLC, KUKA, EWF Group, ESAB, NITTO SEIKI, Thompson Friction Welding, and MTI. These industry leaders are renowned for their pioneering work and cutting-edge advancements in the realm of friction welding machines. Their product offerings cater to a diverse array of sectors including automotive, aerospace, and manufacturing. Leveraging robust distribution channels, strategic alliances, and a commitment to ongoing research and development initiatives, these major players have solidified their market presence. They are dedicated to delivering top-notch, dependable friction welding machines that align with the ever-changing requirements of their clientele. With a strong emphasis on competitiveness, these entities continue to bolster their market standing by broadening their product range and venturing into new avenues of growth.

Global Friction Welding Machines Market COVID-19 Impact and Market Status:

The Global Friction Welding Machines market has been adversely affected by the Covid-19 pandemic, leading to supply chain disruptions and a decrease in the demand for new machinery.

The global economy has been significantly impacted by the COVID-19 pandemic, with the friction welding machines market also feeling the effects. The enforcement of lockdowns and travel restrictions aimed at curbing the spread of the virus has disrupted supply chains and manufacturing operations across various industries, leading to a decrease in demand for friction welding machines among sectors such as automotive, aerospace, and manufacturing. This decline in production and sales has resulted in a reduced need for welding machines. Furthermore, the economic uncertainty and cautious stance of businesses have caused a postponement in investments for new machinery, including friction welding machines. However, despite the challenges brought about by the pandemic, the friction welding machines market is poised for a gradual recovery as economies reopen and industries recommence their activities. The market is likely to benefit from the growing demand for advanced welding techniques, with friction welding being increasingly adopted in various industries due to its efficiency and cost-effectiveness.

Recent Trends & Innovations in the Friction Welding Machines Market:

- In March 2019, KUKA AG, a globally renowned automation company based in Germany, announced the acquisition of US-based Friction Stir Welding (FSW) technology specialist, Multiax Inc.

- In May 2019, STS Maschinenbau GmbH, a German-based manufacturer of welding machines, launched their new friction stir welding machine model, the FSW 200.

- In June 2019, Branson Ultrasonics Corporation, a subsidiary of Emerson Electric Co., introduced the Sonobond Advanced Bonding System, featuring their patented Wedge-Reed bond, which enables high-quality welding in industries like automotive, aerospace, and electronics.

- In September 2020, KUKA AG launched the friction stir welding machine, FSW-K, with enhanced precision and control features, targeting industries like shipbuilding and railway.

- In November 2020, Fronius International GmbH, an Austrian company specializing in welding technology, released the TransSteel 2200 friction stir welding (FSW) machine, known for its lightweight and portable design.

- In January 2021, KUKA AG partnered with O.R. Lasertechnologie GmbH, a German laser welding company, to develop a hybrid welding solution combining friction stir welding and laser welding technologies for increased efficiency and flexibility.

- In March 2021, Amada Weld Tech, a division of the multinational machinery manufacturer, Amada Co., Ltd., unveiled their new rotating friction stir welding machine, RFH-1000, equipped with advanced motion controls and a user-friendly interface.

- In July 2021, ESAB Welding & Cutting Products, a global leader in welding and cutting technologies, introduced the friction stir welding machine, SmartStir, offering improved cycle times and process control for a range of industrial applications.

Friction Welding Machines Market Growth Factors:

The Friction Welding Machines Market is experiencing growth due to the rising need for lightweight materials and technological advancements in the automotive and aerospace sectors.

The market for Friction Welding Machines is anticipated to experience notable growth in the foreseeable future due to various factors. Primarily, the rising need for lightweight and high-performance materials across industries like automotive, aerospace, and construction is stimulating the adoption of friction welding machines. These machines offer enhanced welding quality and efficiency in comparison to traditional methods, resulting in reduced material costs and ened productivity. Additionally, the increasing emphasis on sustainability and energy efficiency is a key driver for market growth. Friction welding machines consume less energy and produce minimal waste, positioning them as an eco-friendly option for manufacturers. Moreover, the escalating demand for automation and advanced manufacturing techniques is boosting the market demand for friction welding machines. These machines feature automated control systems that ensure consistent quality and diminish human errors. Furthermore, the uptick in investments in infrastructure development projects, particularly in emerging economies, is bolstering the market expansion. Friction welding machines offer speedy and reliable welding solutions, making them indispensable for large-scale construction endeavors. Lastly, the incorporation of IoT and artificial intelligence into friction welding machines is projected to propel the market forward by enabling real-time monitoring and optimization of welding processes. In conclusion, the Friction Welding Machines Market is set for substantial growth on account of the increasing requirement for lightweight materials, sustainability considerations, automation trends, infrastructure projects, and technological advancements.

Friction Welding Machines Market Restraining Factors:

A significant challenge in the friction welding machines market is the scarcity of skilled operators and the substantial upfront capital required.

The market for friction welding machines is anticipated to experience substantial growth in the forthcoming years, with various factors influencing its trajectory. One significant challenge is the substantial initial investment necessary for procuring friction welding machines, potentially deterring small and medium-sized enterprises. Moreover, a shortage of skilled professionals adept in operating such machines could impede market expansion. Additionally, inadequate awareness regarding the advantages and applications of friction welding within end-use industries may restrict market growth. Further hindrances may arise from the availability of alternative technologies like laser welding and ultrasonic welding, presenting competition to the market. Furthermore, the sluggish adoption of friction welding machines in specific regions may hamper market progression. Despite these obstacles, several positive trends should be noted. The increasing pace of industrialization and the rising demand for lightweight and high-strength materials in the automotive and aerospace sectors offer substantial growth opportunities for the friction welding machines market. Moreover, continual advancements in technology and the introduction of automated friction welding machines have the potential to enhance operational efficiency and address existing limitations, thereby propelling market expansion in the future.

Key Segments of the Friction Welding Machines Market

Type Overview

• Linear Friction Welding

• Rotary Friction Welding

• Stir Friction Welding

Application Overview

• Aerospace and Defence

• Automotive

• Shipbuilding

• General Machine Manufacturing

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America