Market Analysis and Insights:

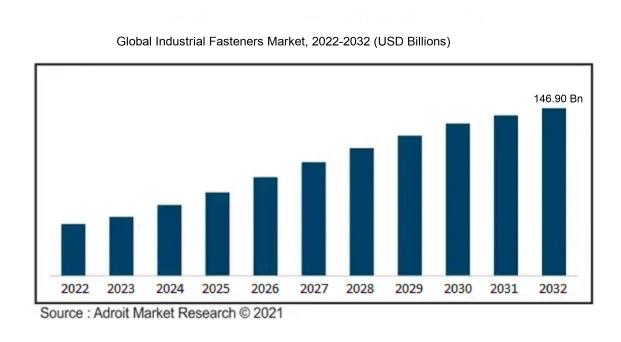

The market for Global Industrial Fasteners was estimated to be worth USD 89.34 billion in 2023, and from 2023 to 2032, it is anticipated to grow at a CAGR of 6.49%, with an expected value of USD 146.90 billion in 2032.

The Industrial Fasteners Market experiences growth driven by various factors. Primarily, the increasing demand from key sectors such as automotive, construction, and aerospace acts as a catalyst for market expansion. These industries heavily depend on fasteners for the assembly, fastening, and securing of components, leading to a rise in the need for industrial fasteners.

Additionally, the industry's emphasis on product quality and compliance with safety standards plays a crucial role in pushing market growth. Manufacturers are compelled to meet stringent quality requirements, resulting in the adoption of advanced fasteners with superior durability and performance. Furthermore, the uptick in the production of lightweight vehicles and aircraft also drives market growth, as specialized fasteners are necessary for lightweight material applications. The booming global construction sector, accompanied by urbanization and infrastructure development projects, boosts the demand for industrial fasteners. Lastly, the increasing popularity of e-commerce platforms for sourcing industrial fasteners provides convenience and accessibility, further fueling market expansion. These combined factors contribute to the continuous growth of the Industrial Fasteners Market.

Industrial Fasteners Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2032 |

| Study Period | 2018-2032 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2032 | USD 146.90 billion |

| Growth Rate | CAGR of 6.49% during 2023-2032 |

| Segment Covered | By Material, By Product, By Application, By Distribution Channel, By Type, By Bolt Size, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Fastenal Company, Arconic Inc., Stanley Black & Decker, Inc., ITW Engineered Fasteners and Components, Precision Castparts Corp., LISI Group, Illinois Tool Works Inc., Nifco Inc., Penn Engineering & Manufacturing Corporation, and Sundram Fasteners Limited. |

Market Definition

Industrial fasteners are intricate mechanical tools employed for the purpose of connecting or securing multiple objects in a wide array of industrial sectors. These components are meticulously crafted to deliver robust and dependable linkages in the realms of manufacturing and construction practices.

Industrial fasteners are indispensable components utilized across a range of manufacturing industries like automotive, aerospace, construction, and machinery. These integral pieces play a vital role in securely joining various parts together, ensuring the overall strength and safety of the end products.

Nuts, bolts, screws, and rivets are among the primary types of industrial fasteners that provide a durable and long-lasting connection capable of withstanding high stress levels, vibrations, and challenging environmental conditions. The quality of these fasteners significantly influences the longevity and performance of the final goods, underscoring their critical role in manufacturing operations. Opting for the appropriate type and dimensions of fasteners not only boosts efficiency and reduces assembly time but also diminishes the likelihood of costly rework or product malfunctions.

Consequently, it is imperative for manufacturers to meticulously choose and deploy high-quality industrial fasteners to uphold the integrity and effectiveness of their offerings.

Key Market Segmentation:

Insights On Key Material

Steel

Steel is the material that is expected to dominate the Global Industrial Fasteners Market. Steel fasteners are widely used in various industries, including automotive, construction, and machinery. They offer exceptional strength, durability, and resistance to corrosion, making them ideal for heavy-duty applications. The high demand for steel fasteners can be attributed to their reliability and cost-effectiveness. Additionally, advancements in steel manufacturing technology have further enhanced the quality and performance of steel fasteners, solidifying their position as the dominant part in the Global Industrial Fasteners Market.

Metal

While steel is expected to dominate the market, other metals such as aluminum and other non-steel alloys will also hold a significant share. Aluminum fasteners find applications in sectors where weight reduction is crucial, like aerospace and automotive industries. Non-steel alloy fasteners offer specific properties, such as high temperature resistance and excellent conductivity, making them suitable for energy and electrical applications. Although not as prevalent as steel, these metal parts will continue to be in demand for their unique characteristics and specific industry requirements.

Plastic

Plastic fasteners are widely used in various industries due to their lightweight nature, corrosion resistance, and cost-effectiveness. They find applications in sectors like electronics, automotive, and consumer goods. However, their usage is more prevalent in non-structural and non-heavy-duty applications where strength requirements are relatively low. While plastic fasteners offer advantages in certain scenarios, they are not expected to dominate the Global Industrial Fasteners Market due to their limited strength and durability compared to metal counterparts.

Others

The Others category comprises a variety of materials such as composites, ceramics, and hybrid fasteners. These materials are often used in specific industries and niche applications that demand unique properties. For example, composite fasteners are known for their lightweight and corrosion-resistant properties, making them suitable for the marine industry. Ceramics are used in applications that require high-temperature resistance, such as aerospace and propulsion systems. Though these parts offer distinct advantages, their significant market presence is limited to specific industries, resulting in them not expected to dominate the Global Industrial Fasteners Market.

### Global Industrial Fasteners Market Segmentation by Material

Aluminum

Aluminum fasteners represent a significant subsegment within the global industrial fasteners market. Known for their lightweight properties, corrosion resistance, and versatility, aluminum fasteners find extensive applications across various industries. The use of aluminum fasteners is particularly prevalent in sectors where weight reduction is crucial, such as aerospace and automotive industries. Their durability and ability to withstand harsh environments make them a preferred choice in demanding applications. As the market continues to evolve, the demand for aluminum fasteners is expected to grow further, driven by the increasing emphasis on lightweight materials and sustainability in manufacturing processes.

Insights On Key Product

Internally Threaded Fasteners

Among the various sectors in the Product category of the Global Industrial Fasteners Market, Internally Threaded Fasteners are expected to dominate. This can be attributed to their wide range of applications in various industries, including automotive, construction, and machinery. Internally threaded fasteners, such as bolts and screws, provide strong and secure connections. They are preferred over externally threaded fasteners in situations where a smooth surface is required or when tampering needs to be prevented. Moreover, the increasing demand for customized solutions and the growth of industries such as automotive and aerospace are contributing to the dominance of internally threaded fasteners in the market.

Externally Threaded Fasteners

Externally Threaded Fasteners represent another important product in the Global Industrial Fasteners Market. While they may not dominate the market like their internally threaded counterparts, externally threaded fasteners, including nuts and bolts, play a crucial role in various industries. They are extensively used for fastening components together and providing mechanical strength. The demand for externally threaded fasteners is driven by industries such as construction, manufacturing, and infrastructure development, where secure and reliable connections are essential. Although not expected to be the dominating part, externally threaded fasteners hold significant market share due to their widespread usage across different sectors.

Non-threaded Fasteners

Non-threaded Fasteners, such as rivets, retain an important position in the Global Industrial Fasteners Market. While they may not dominate the market in terms of overall volume, their specific applications make them indispensable in certain industries. Non-threaded fasteners offer advantages such as quick installation, high load-bearing capacity, and resistance to vibration and loosening. These characteristics make them particularly suitable for applications in industries like aerospace, automotive, and construction, where structural integrity and reliability are paramount. Although not expected to be the leading part, non-threaded fasteners hold considerable market share due to their unique properties and specialized applications.

Aerospace Grade Fasteners

The Aerospace Grade Fasteners product, specifically designed to meet the demanding requirements of the aerospace industry, holds a niche position in the Global Industrial Fasteners Market. These fasteners must comply with strict quality standards and endure harsh environments, including extreme temperature variations, high vibrations, and corrosive conditions. Aerospace grade fasteners, including bolts, screws, and rivets, play a critical role in ensuring the safety and integrity of aircraft structures. Despite their limited application scope, the aerospace industry's stringent regulations and continuous technological advancements contribute to the consistent demand for aerospace grade fasteners. However, this part is not expected to dominate the overall industrial fasteners market due to its specialized nature and narrower customer base.

Insights On Key Application

Automotive

The Automotive application is expected to dominate the Global Industrial Fasteners Market. This is primarily due to the high demand for fasteners in the automotive industry, driven by the production and sales of automobiles worldwide. Fasteners play a crucial role in ensuring the structural integrity and safety of vehicles, as well as in the assembly of various automotive components. With the increasing focus on lightweight materials and advanced manufacturing processes in the automotive sector, the demand for specialized fasteners is likely to remain strong.

Others

The Others category is a broad that includes various applications not specifically mentioned in the list. This part encompasses niche industries and unique applications that may require specialized fasteners. While it is challenging to determine the dominating application within this category without further details, it can be inferred that this part may include specific industries with specific requirements. The dominating part within the "Others" category would depend on individual market dynamics, customer needs, and technological advancements.

Building & Construction

The Building & Construction application is an important market for industrial fasteners. The industry's growth is fueled by factors such as population growth, urbanization, and investments in infrastructure development. Fasteners are crucial in construction projects, ensuring the stability, durability, and safety of structures. With the increase in construction activities worldwide, including residential, commercial, and industrial projects, the demand for industrial fasteners in the building and construction sector is anticipated to be substantial.

Industrial Machinery

The Industrial Machinery application is expected to have a significant presence in the Global Industrial Fasteners Market. Fasteners play a crucial role in the assembly and maintenance of industrial machinery across various sectors, including manufacturing, energy, and transportation. As industrial machinery continues to be developed and manufacturing processes become more advanced, the demand for fasteners that can withstand high levels of stress and vibrations is expected to increase. Therefore, the industrial machinery part is likely to have a strong impact on the global market for industrial fasteners.

Home Appliances

The Home Appliances application is an important market for industrial fasteners, albeit relatively smaller compared to others. Fasteners are essential in the assembly of home appliances such as refrigerators, washing machines, dishwashers, and ovens. As the demand for energy-efficient and technologically advanced home appliances grows, the need for fasteners that can secure various components and withstand everyday usage is expected to rise. While this part may not dominate the global market, it is still a significant sector within the Industrial Fasteners Market.

Aerospace

The Aerospace application within the Industrial Fasteners Market is another crucial application area. The aerospace industry demands fasteners that meet strict requirements for reliability, durability, and safety. Fasteners used in aerospace applications must be able to withstand extreme temperatures, pressures, and vibrations, while also being lightweight. With the growth of the global aerospace sector, driven by increasing air travel and defense spending, the demand for aerospace-grade fasteners is expected to be substantial. Although it may not dominate the entire market, the aerospace part holds substantial significance and growth potential in the Industrial Fasteners Market.

Lawns And Gardens

The Lawns and Gardens application represents a niche market within the Industrial Fasteners Market. Fasteners in this application area are primarily used for securing components in outdoor furniture, garden equipment, and agricultural machinery. While this part may not dominate the overall market, it caters to specific needs within the lawns and gardens industry. Factors such as lifestyle changes, urban gardening trends, and the rising popularity of outdoor living spaces can contribute to the demand for fasteners in this part.

Motors and Pumps

The Motors and Pumps industry is another important application area within the Industrial Fasteners Market. Fasteners are crucial for securing components in motors and pumps used across various industries, such as manufacturing, oil and gas, and agriculture. As industries rely on motors and pumps for their operations, the demand for reliable and strong fasteners to ensure operational efficiency will remain significant. While this part may not dominate the overall market, it plays a crucial role in supporting industrial processes and infrastructure.

Furniture

The Furniture application represents another niche market within the Industrial Fasteners Market. Fasteners used in furniture assembly are primarily focused on securing components to ensure stability and durability. The demand for fasteners in the furniture industry is driven by factors such as changing consumer preferences, interior design trends, and the growth of the housing and hospitality sectors. While the furniture part may not have a dominating presence in the global market, it caters to specific needs within the furniture industry and contributes to the Industrial Fasteners Market.

Plumbing Products

The Plumbing Products industry encompasses fasteners used in plumbing systems, including pipes, fittings, and fixtures. While this part may not dominate the overall market, it holds importance in the construction and maintenance of plumbing infrastructure. The growth of the global construction industry, combined with the need for efficient plumbing systems in residential, commercial, and industrial applications, drives the demand for fasteners in the plumbing products part. Although relatively smaller than some other parts, it plays a crucial role in ensuring the integrity and functionality of plumbing systems.

Insights On Key Distribution Channel

Indirect Distribution Channel

The indirect distribution channel is expected to dominate the global Industrial Fasteners market. This distribution channel involves the use of intermediaries such as wholesalers, retailers, and resellers to reach the end customers. The dominance of the indirect distribution channel can be attributed to the widespread presence of these intermediaries across various regions. Through this channel, manufacturers can effectively reach a larger customer base, improve their market reach, and ensure efficient product availability. Additionally, the extensive distribution networks established by wholesalers and retailers enable timely deliveries and provide localized support to customers, further enhancing the dominance of the indirect distribution channel.

Direct Distribution Channel

Direct distribution channel, on the other hand, refers to the distribution of industrial fasteners directly from the manufacturer to the end customers. While this channel offers certain advantages such as better control over pricing, branding, and customer relationships, it is expected to play a secondary role in dominating the global Industrial Fasteners market. Direct distribution channels are often utilized by manufacturers for specialized or customized products, where direct interaction with the customers is necessary. However, due to the complexity of logistics and the vast customer base that requires wider market coverage, the dominance lies with the indirect distribution channel.

Insights On Key Type

Threaded Fasteners

Threaded fasteners are expected to dominate the Global Industrial Fasteners Market. These fasteners are widely used in various industries such as automotive, construction, and aerospace, among others. The threaded fasteners includes screws, bolts, and studs, which are essential components for joining and securing two or more parts together. The increasing demand for durable and reliable fastening solutions, coupled with the rising industrial activities across the globe, drives the growth of the threaded fasteners market. Moreover, the versatility and ease of application of threaded fasteners further contribute to their dominance in the global market.

Nuts

Nuts, although not the dominating sector, play a significant role in the Global Industrial Fasteners Market. Nuts are widely utilized alongside bolts and screws to provide a secure fastening connection. They come in various types, including hex nuts, wing nuts, and lock nuts, among others. The demand for nuts is driven by their crucial role in various industries, such as automotive, machinery, and construction. While nuts may not dominate the market solely, their importance as complementary components to threaded fasteners cannot be undermined.

Washers

Similarly, washers are an essential type within the Global Industrial Fasteners Market. Washers are used in conjunction with screws, bolts, and nuts to distribute the load, prevent loosening, and protect the connected surfaces from damage. They come in different forms, with the most common being flat washers and spring washers. The demand for washers is driven by their functional benefits, such as improving fastener stability and preventing corrosion. Although not the dominant part, washers are a crucial component in fastening systems and contribute significantly to the overall market.

Rivets

Rivets, while playing a vital role, are expected to be the least dominant part within the Global Industrial Fasteners Market. Rivets are used to permanently join two or more materials together and find extensive applications in automotive, aerospace, and construction industries. However, compared to other types of fasteners such as threaded fasteners, nuts, and washers, the demand for rivets is relatively lower. This can be attributed to the specific nature of rivet installations, which require specialized tools and expertise. Nonetheless, rivets remain relevant in certain industries and applications where they excel in providing strong and secure connections.

Insights On Key Bolt Size

Less Than 1/4

The Less Than 1/4 bolt size is expected to dominate the Global Industrial Fasteners Market. This is primarily due to the widespread use of smaller-sized bolts in various industrial applications. The demand for fasteners in industries such as electronics, automotive, and aerospace is driving the growth of this part. Smaller bolt sizes are commonly used for assembling and securing smaller components, making them essential in many industries. Additionally, advancements in technology have led to the miniaturization of various products, further increasing the demand for fasteners in the "Less Than 1/4" bolt size range.

1/4 to 3/4

The 1/4 to 3/4 range within the Bolt Size category holds significant importance in the Global Industrial Fasteners Market. This range caters to a diverse range of applications across various industries. It encompasses bolts that are commonly used in construction, infrastructure development, machinery, and general manufacturing. The versatility and wide application scope contribute to the dominance of this part. The demand for medium-sized bolts within this range is driven by the growth in construction activities, expanding industrial sectors, and the need for secure and reliable fastening solutions.

3/4 to 1

While the 3/4 to 1 range of Bolt Size is not expected to dominate the Global Industrial Fasteners Market, it continues to hold importance in certain industries. This range is commonly used in heavy-duty applications that require a higher level of strength and load-bearing capacity. Sectors such as heavy machinery, infrastructure, and energy generation rely on this part for secure fastening solutions. Although the overall demand for this bolt size range may not be as significant as others, it remains an essential part of the industrial fasteners market.

More Than 1

The More Than 1 range within the Bolt Size category caters to specific industrial requirements, but it is not expected to dominate the Global Industrial Fasteners Market. These larger-sized bolts are typically utilized in heavy industries and specialized applications where extreme loads and forces need to be handled. Sectors such as oil and gas, shipbuilding, and large-scale infrastructure projects often require fasteners in this size range. While the demand for this part may be limited compared to others, it remains significant within its niche market and plays a crucial role in ensuring robust and durable fastening solutions.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the Global Industrial Fasteners market. The region has seen significant growth in recent years due to the rapid industrialization and infrastructural development in countries such as China, India, and Japan. These countries have a high demand for industrial fasteners in sectors like automotive, construction, and manufacturing. Additionally, the region is witnessing technological advancements and a rising focus on sustainability, which is driving the demand for specialized fasteners. Moreover, the presence of key market players and favorable government policies supporting industrial development further contribute to the dominance of Asia Pacific in the Global Industrial Fasteners market.

North America

North America is one of the prominent regions in the Global Industrial Fasteners market. The region has a well-established industrial sector, particularly in the automotive and aerospace industries. The demand for high-quality and reliable fasteners in these sectors drives the market growth. Furthermore, the region's emphasis on research and development, along with technological advancements, boosts the adoption of advanced fasteners. The presence of major manufacturers and suppliers in North America further strengthens the market. However, the market is relatively mature in this region, leading to moderate growth compared to emerging markets like Asia Pacific.

Europe

Europe is a significant market for industrial fasteners. The region has a strong manufacturing base, especially in sectors like automotive, machinery, and construction. The demand for fasteners in these industries fuels the growth of the market. Additionally, the region's strict quality standards and regulations for fasteners ensure a high level of product reliability and safety. Europe also places a strong emphasis on sustainability and environmental protection, leading to the adoption of eco-friendly fasteners. However, the market in Europe is influenced by economic fluctuations and geopolitical factors, which impact the growth rate.

Latin America

Latin America is an emerging market for industrial fasteners. The region's growing manufacturing sector, coupled with infrastructure development projects, contributes to the demand for fasteners. Countries like Brazil, Mexico, and Argentina are witnessing increased investments in industries such as automotive, construction, and energy, driving the market growth. However, the market in Latin America is relatively fragmented, with numerous small and medium-sized enterprises operating in the industry. This fragmentation, along with economic uncertainties in the region, poses challenges to the overall market growth.

Middle East & Africa

The Middle East & Africa region is also experiencing growth in the industrial fasteners market. The region's focus on infrastructure development, particularly in countries like Saudi Arabia, UAE, and South Africa, drives the demand for fasteners. The construction industry in the region, along with investments in oil and gas projects, contributes significantly to the market growth. However, the market is affected by fluctuations in oil prices, political instability, and regional conflicts, which can hinder market expansion. Nonetheless, the region's untapped potential and increasing industrial activities make it an important market for industrial fasteners.

Company Profiles:

Key participants in the worldwide Industrial Fasteners sector are essential for producing and delivering a diverse array of fastening solutions to multiple industries, thereby securing the dependability and robustness of assembled parts. Their efforts fuel market expansion through groundbreaking product offerings, adherence to quality benchmarks, and the provision of effective distribution channels.

Prominent companies in the Industrial Fasteners Market comprise Fastenal Company, Arconic Inc., Stanley Black & Decker, Inc., ITW Engineered Fasteners and Components, Precision Castparts Corp., LISI Group, Illinois Tool Works Inc., Nifco Inc., Penn Engineering & Manufacturing Corporation, and Sundram Fasteners Limited. These organizations are pivotal stakeholders in the industrial fasteners sector, offering a diverse array of fastening solutions tailored to meet the requirements of industries such as automotive, aerospace, construction, and electronics. Their commitment to delivering top-notch products, cutting-edge technologies, and exceptional customer support underscores their dedication to addressing the varied fastening demands of clients on a global scale. Furthermore, they frequently partake in strategic alliances, mergers and acquisitions, and endeavors in product innovation to fortify their market presence and secure a competitive advantage within the industrial fasteners domain.

COVID-19 Impact and Market Status:

The global market for industrial fasteners has been greatly impacted by the Covid-19 pandemic, resulting in a decrease in demand and disturbances in supply chains.

The industrial fasteners market has been significantly impacted by the global COVID-19 pandemic. Lockdown measures and strict movement restrictions in various countries have led to a decrease in demand for industrial fasteners.

The manufacturing industry, a major consumer of these fasteners, has been hit hard by supply chain disruptions, reduced production capacities, and lower demand for goods. Similarly, the construction sector, another important user of fasteners, has experienced a slowdown in operations due to restrictions and labor shortages, resulting in decreased demand for fasteners in construction projects. Moreover, uncertainties surrounding the global economy and the pandemic have made businesses more cautious, leading to delays or cancellations of investments in new projects, further affecting the demand for industrial fasteners. As countries gradually lift restrictions and economic recovery progresses, there is anticipated to be a gradual rebound in demand for industrial fasteners. However, it may take some time for the market to fully recuperate to pre-pandemic levels.

Latest Trends and Innovation:

- March 2021: Stanley Black & Decker acquired Excel Industries, a leading manufacturer of industrial fasteners, to expand their presence in the fasteners market.

- April 2020: Illinois Tool Works (ITW) launched a new range of high-performance industrial fasteners, featuring advanced technology for enhanced durability and strength.

- September 2019: Nucor Corporation completed the acquisition of American Industrial Company (AIC), a major player in the industrial fasteners industry, further strengthening their position in the market.

- January 2018: Arconic Inc. announced the development of a breakthrough technology for industrial fasteners, offering enhanced corrosion resistance and improved structural integrity.

- July 2017: Bulten AB, a leading supplier of fasteners to the automotive industry, expanded its operations by acquiring PSM International Holdings Limited, a global manufacturer of specialty fasteners.

- November 2016: Würth Group introduced a range of innovative fasteners with integrated sensors, enabling real-time monitoring of critical components in various industrial applications.

Significant Growth Factors:

The expansion of the Industrial Fasteners Market can be credited to elements like the escalating pace of industrial development, burgeoning construction projects, and the expanding automotive sector.

The industrial fasteners industry is currently experiencing significant expansion driven by various key factors. A crucial contributor to this growth is the global construction sector's rapid development. The escalating demand for residential and commercial buildings has led to an increased need for fasteners like screws, bolts, and nuts. Furthermore, the automotive sector, particularly in emerging markets, is witnessing growth, resulting in ened demand for fasteners for vehicle assembly and production. Another significant growth driver is the expanding industrial production and manufacturing activities, necessitating fasteners to securely connect various components as companies scale their operations. Additionally, the upsurge in infrastructure development and investments in sectors such as renewable energy, aerospace, and defense are propelling the demand for industrial fasteners. Moreover, the market is experiencing growth due to the increased focus on lightweight and environmentally friendly fasteners, aimed at enhancing fuel efficiency and reducing carbon emissions. Technological advancements in fastener manufacturing processes have also played a substantial role by enabling the production of high-performance and long-lasting fasteners. The growing prevalence of e-commerce platforms has further contributed to market expansion, offering convenient access to a diverse range of fasteners for both industrial and individual consumers. With these driving factors at play, the industrial fasteners market is poised for significant growth in the foreseeable future.

Restraining Factors:

The intricate and continuously changing regulatory environment presents notable obstacles to the expansion of the Industrial Fasteners Market.

The industrial fasteners market encounters various challenges that impede its expansion. Fluctuations in the prices of raw materials, particularly steel and aluminum, present difficulties for manufacturers by impacting profitability and pricing strategies. Furthermore, strict regulatory standards governing fastener production and sales contribute to increased operational costs and compliance obligations. The market's high fragmentation, characterized by numerous small-scale players, intensifies competition and price conflicts, making it challenging for larger companies to secure contracts and sustain profit margins.

Key Segments of the Industrial Fasteners Market

Material Overview

• Metal

• Plastic

• Steel

• Aluminum

• Others

Product Overview

• Externally Threaded Fasteners

• Internally Threaded Fasteners

• Non-threaded Fasteners

• Aerospace Grade Fasteners

Application Overview

• Automotive Fasteners

• Aerospace Fasteners

• Building & Construction Fasteners

• Industrial Machinery Fasteners

• Home Appliances Fasteners

• Lawns and Gardens Fasteners

• Motors and Pumps Fasteners

• Furniture Fasteners

• Plumbing Products Fasteners

• Other Application Fasteners

Distribution Channel Overview

• Direct Distribution

• Indirect Distribution

Type Overview

• Threaded Fasteners

• Nuts Fasteners

• Washers Fasteners

• Rivets Fasteners

Bolt Size Overview

• Less Than 1/4

• 1/4 to 3/4

• 3/4 to 1

• More Than 1

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• UK

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America