Market Analysis and Insights:

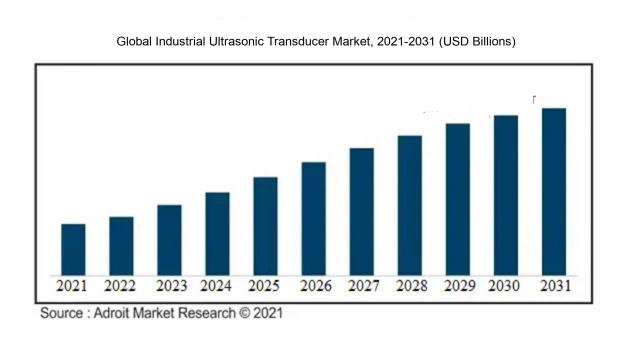

The market for Global Industrial Ultrasonic Transducer was estimated to be worth USD XX billion in 2021, and from 2021 to 2031, it is anticipated to grow at a CAGR of XX%, with an expected value of USD XX billion in 2031.

The Industrial Ultrasonic Transducer Market is driven by various significant factors. Primarily, the increasing need for ultrasonic transducers in diverse industrial sectors serves as a key driving force. Sectors like automotive, healthcare, food and beverage, and electronics are progressively integrating ultrasonic technology for activities such as cleaning, welding, and measurement. Secondly, the constant advancements in ultrasonic transducer technology, including enhanced sensor sensitivity and accuracy, contribute to improved performance and reliability, thus boosting market expansion. Moreover, the growing emphasis on process automation and Industry 4.0 is generating substantial demand for ultrasonic transducers, crucial for enabling real-time monitoring and control systems. Additionally, the escalating awareness surrounding energy efficiency and environmental sustainability is promoting the adoption of ultrasonic transducers due to their low power consumption and environmentally friendly characteristics. These combined factors are anticipated to propel the Industrial Ultrasonic Transducer Market's growth in the forthcoming years.

Industrial Ultrasonic Transducer Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD XX billion |

| Growth Rate | CAGR of XX% during 2021-2031 |

| Segment Covered | By Type, By Application, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Branson Ultrasonics Corporation, Emerson Electric Co., Siemens AG, Telsonic AG, Rinco Ultrasonics AG, Crest Ultrasonics Corp., Noliac A/S, APC International Ltd., and Olympus Corporation. |

Market Definition

An industrial ultrasonic transducer functions as a mechanism for transforming electrical energy into high-frequency sound waves, serving a range of purposes including cleaning, welding, and measurement tasks within industrial environments. Its operational basis lies in the piezoelectric effect, where the generation of ultrasonic vibrations is triggered in a piezoelectric material upon exposure to an electrical signal.

The Industrial Ultrasonic Transducer is an essential component in a wide range of industrial settings. Employing sound waves at frequencies beyond the audible spectrum, these devices are instrumental in the detection and measurement of objects and materials. Their application spans various industries including healthcare, automotive, food processing, and manufacturing. The capability of ultrasonic transducers to produce and sense high-frequency sound waves is critical for tasks like non-destructive testing, distance measurement, level sensing, and flaw detection. Renowned for their precision, dependability, and effectiveness, ultrasonic transducers are pivotal tools in enhancing productivity, ensuring quality control, and improving safety across diverse industrial environments.

Key Market Segmentation:

Insights On Key Type

Delay Line Transducer

The Delay Line Transducer is expected to dominate the Global Industrial Ultrasonic Transducer Market. This part offers several advantages, making it the preferred choice for various industrial applications. Delay Line Transducers are designed to measure material thickness and are highly accurate in detecting flaws or irregularities in objects. Their ability to generate consistent and reliable results, combined with their durability and longevity, has positioned them as the dominant part in the market. Additionally, their versatility in working with different materials and surfaces further contributes to their dominance.

Contact Transducer

Contact Transducers are widely utilized in the Global Industrial Ultrasonic Transducer Market due to their simplicity and cost-effectiveness. These transducers are suitable for applications requiring direct contact with the material being tested. They are commonly used in ultrasonic thickness gauges and flaw detectors. Although the Contact Transducer part offers convenience and affordability, it lacks the flexibility and precision of other parts, limiting its dominance in the market.

Dual Element Transducer

Dual Element Transducers are popular in industrial applications that require increased resolution and sensitivity. This part utilizes two separate elements for transmitting and receiving signals, allowing for better differentiation between surface and subsurface defects. While Dual Element Transducers offer improved accuracy and versatility compared to Contact Transducers, they are not expected to dominate the market due to their higher cost and complexity.

Immersion Transducer

Immersion Transducers are commonly used in non-destructive testing applications that require high-frequency ultrasonic waves. This part excels in applications such as flaw detection and thickness measurement in liquids or submerged environments. However, the specialized nature of Immersion Transducers limits their overall dominance in the Global Industrial Ultrasonic Transducer Market.

Shear Wave Transducer

Shear Wave Transducers are known for their ability to produce horizontally polarized waves, which are useful in detecting flaws in welds and other critical joints. This part offers superior sensitivity to certain defects and is often used in industries such as oil and gas, aerospace, and automotive manufacturing. Despite their specific niche applications, Shear Wave Transducers are not expected to dominate the overall market due to their limited versatility and specialized nature.

Insights On Key Application

Level and Measurement

The Level and Measurement application is expected to dominate the Global Industrial Ultrasonic Transducer Market. This is because ultrasonic transducers play a crucial role in level and measurement applications across various industries such as oil and gas, chemical, and manufacturing. The ability of ultrasonic transducers to accurately measure and monitor liquid or solid levels, distance, and position makes them highly sought after in industrial settings. This part is likely to dominate the market due to the increasing demand for precise and reliable level and measurement solutions.

NDT

The NDT (Non-Destructive Testing) application is another significant part of the Global Industrial Ultrasonic Transducer Market. NDT techniques are widely used across industries to detect flaws, defects, and material integrity without causing damage. Ultrasonic transducers are vital components in NDT equipment as they generate and receive ultrasonic waves to assess the internal and surface conditions of objects. With the growing emphasis on quality control and safety regulations, the demand for NDT applications utilizing ultrasonic transducers is expected to rise.

Production Process Control

The Production Process Control application holds significance in the Global Industrial Ultrasonic Transducer Market. These transducers are utilized to monitor and control various production processes, such as welding, machining, and assembly. Ultrasonic transducers are employed to ensure precision, efficiency, and quality in manufacturing operations. The ability to detect irregularities, defects, or variations in real-time allows for immediate corrective actions and enhances overall productivity. With the increasing focus on optimizing production processes and maintaining high standards, the demand for ultrasonic transducers in production process control is projected to grow.

Others

The Others category refers to applications beyond the specific categories mentioned above. While this part may encompass a wide range of applications, it is not expected to dominate the Global Industrial Ultrasonic Transducer Market. The dominating parts such as level and measurement, NDT, and production process control have more defined and industry-specific requirements, resulting in higher demand for ultrasonic transducers. The "Others" category may include niche or specialized applications where ultrasonic transducers are utilized but on a relatively smaller scale compared to the dominant parts.

Insights on Regional Analysis:

Europe

Europe is expected to dominate the Global Industrial Ultrasonic Transducer market. This can be attributed to various factors such as the presence of a strong industrial base, technological advancements, and a favorable regulatory environment. Europe has a well-established manufacturing sector, particularly in countries like Germany, France, and the United Kingdom, which are known for their expertise in industries such as automotive, aerospace, and healthcare. The high demand for ultrasonic transducers in these industries, coupled with the focus on innovation and automation, is driving the growth of the market in Europe. Additionally, the region is home to several key players in the ultrasonic transducer market, further contributing to its dominance.

Asia Pacific

Asia Pacific is a significant player in the Global Industrial Ultrasonic Transducer market. The region is characterized by rapid industrialization and technological advancements, particularly in countries like China, India, Japan, and South Korea. These countries have a strong presence in various manufacturing sectors, such as electronics, automotive, and consumer goods. The increasing adoption of ultrasonic transducers in applications like cleaning, welding, and testing in these industries is driving the market growth in Asia Pacific. Moreover, the region has a large consumer base, which further amplifies the demand for industrial ultrasonic transducers.

North America

North America holds considerable potential in the Global Industrial Ultrasonic Transducer market. The region is home to several prominent industries, including automotive, healthcare, oil and gas, and aerospace. These industries require ultrasonic transducers for various applications such as non-destructive testing, precision cleaning, and distance measurement. Moreover, North America is known for its technological advancements and significant research and development activities. The presence of key market players and the emphasis on automation and efficiency in industrial processes contribute to the growth of the ultrasonic transducer market in this region.

Latin America

Latin America is a growing market for Industrial Ultrasonic Transducers. The region is witnessing increasing industrialization and infrastructural development, particularly in countries like Brazil and Mexico. Key industries such as automotive, food and beverage, and pharmaceuticals are undergoing expansion, driving the demand for ultrasonic transducers. Additionally, there is a growing awareness of the benefits of ultrasonic technology in the region, leading to the increased adoption of ultrasonic transducers in various applications. However, the market in Latin America is still evolving and has significant growth potential in the coming years.

Middle East & Africa

The Middle East & Africa region is witnessing steady growth in the Global Industrial Ultrasonic Transducer market. The region is characterized by a diverse industrial landscape, including industries such as oil and gas, petrochemicals, and power generation. Ultrasonic transducers are widely used in these sectors for applications like leak detection, corrosion monitoring, and thickness measurement. Furthermore, there is a growing focus on industrial automation and efficiency, which is driving the demand for ultrasonic transducers in the region. While the market in the Middle East & Africa is not as prominent as in other regions, it is expected to witness significant growth opportunities in the near future.

Company Profiles:

Prominent participants in the worldwide Industrial Ultrasonic Transducer industry specialize in the production and distribution of top-tier ultrasonic transducers for a wide range of industrial purposes, including cleaning, detection, and measurement. Their contributions drive technological progress and cater to the increasing need for effective and dependable ultrasonic solutions.

Prominent companies in the Industrial Ultrasonic Transducer Market encompass Branson Ultrasonics Corporation, Emerson Electric Co., Siemens AG, Telsonic AG, Rinco Ultrasonics AG, Crest Ultrasonics Corp., Noliac A/S, APC International Ltd., and Olympus Corporation. These renowned organizations are deeply engaged in the production and supply of industrial ultrasonic transducers and associated solutions. They have solidified their stature as frontrunners in the industry due to their diverse product offerings, cutting-edge technologies, and widespread global presence. These key entities persistently endeavor to maintain a competitive edge by dedicating resources to research and development endeavors, forging strategic alliances, and engaging in mergers and acquisitions to broaden their market reach and enrich their product lines. Leveraging their robust market positioning and profound industry knowledge, these corporations play a pivotal role in the expansion and progression of the industrial ultrasonic transducer market.

COVID-19 Impact and Market Status:

The global industrial ultrasonic transducer market has experienced adverse effects as a result of the Covid-19 pandemic, causing a reduction in demand and significant disruptions in the supply chain.

The Industrial Ultrasonic Transducer Market has faced notable challenges as a result of the global impact of the COVID-19 pandemic. Disruptions in supply chains and manufacturing operations, along with decreased industrial activities across diverse sectors, have significantly influenced the market dynamics. The implementation of lockdown measures and restrictions on movement has presented obstacles for industries in maintaining production levels and executing new projects. Consequently, there has been a noticeable decrease in the demand for industrial ultrasonic transducers, utilized in applications like cleaning, flaw detection, and liquid processing. The temporary shutdown of manufacturing facilities and reduced investment in new projects further contributed to the decline in market demand. Nevertheless, as the world gradually recovers from the pandemic and economic operations resume, a resurgence in the market is anticipated in the forthcoming years. Industries are expected to focus on investing in innovative technologies, including ultrasonic transducers, to optimize their processes and improve efficiency. The emphasis on hygiene and cleanliness in sectors such as healthcare and food processing is projected to be a driving force for the demand for ultrasonic cleaning transducers. Despite the initial setbacks caused by the pandemic, the long-term outlook for the Industrial Ultrasonic Transducer Market appears promising as industries adapt to the post-COVID-19 landscape.

Latest Trends and Innovation:

- February 2019: Branson Ultrasonics Corporation, a subsidiary of Emerson Electric Co., acquired Whitelegg Machines Limited, a UK-based company specializing in ultrasonic metal joining equipment, to strengthen its product portfolio and expand its presence in the industrial ultrasonic transducer market.

- June 2020: Siemens AG announced the development of a new ultrasonic transducer technology that offers improved performance and reliability for industrial applications. The technology has been successfully integrated into their existing product lines, enhancing their competitive position in the market.

- September 2020: Noliac A/S, a leading manufacturer of high-performance piezoelectric transducers, merged with PiezoMotor Uppsala AB, a Swedish company specializing in precision motion control solutions. The merger resulted in a stronger market presence and broader product offering for both companies in the industrial ultrasonic transducer market.

- December 2020: Third Wave Systems, a provider of machining simulation software, partnered with Optomec, a leading manufacturer of industrial 3D printers, to develop a new ultrasonic transducer-based additive manufacturing system. The collaboration aims to revolutionize the production of complex metal parts for various industries.

- March 2021: Emerson Electric Co. announced the acquisition of Potomac Instruments, Inc., a company specializing in ultrasonic testing equipment. The acquisition allows Emerson to expand its capabilities in non-destructive testing solutions and further strengthen its position in the industrial ultrasonic transducer market.

- July 2021: MISTRAS Group, Inc., a global provider of asset protection solutions, acquired Physical Acoustics Corporation, an innovative company in the field of ultrasonic monitoring and inspection technologies. The acquisition adds advanced ultrasonic transducer-based solutions to MISTRAS' product portfolio, enhancing its offerings for industrial customers.

Significant Growth Factors:

Factors driving the expansion of the Industrial Ultrasonic Transducer Market comprise of the rising need for non-destructive testing solutions, technological innovations, and the escalating utilization across various sectors including automotive, healthcare, and food & beverage industries.

The industrial market for ultrasonic transducers is anticipated to undergo substantial expansion owing to several key drivers. An escalating need for ultrasonic technology in diverse sectors like automotive, healthcare, and manufacturing is propelling market growth. Ultrasonic transducers play a pivotal role in tasks such as cleaning, welding, testing, and inspection, which are extensively employed across these industries. Furthermore, the rising acceptance of ultrasound technology for non-destructive testing and flaw detection in industrial settings is amplifying market progression. Ultrasonic transducers exhibit high efficacy in identifying defects, cracks, and leaks, offering precise and dependable outcomes. Additionally, the evolution of ultrasonic transducer technology, including the creation of high-frequency transducers and the incorporation of advanced materials, is fostering market expansion. These innovations enhance the efficiency and longevity of transducers, resulting in ened demand. Moreover, the mounting emphasis on energy-efficient and environmentally sustainable solutions in various sectors is fortifying the market for ultrasonic transducers, as they present benefits such as decreased energy consumption and reduced environmental impact in comparison to conventional techniques. Moreover, the uptrend in investments towards research and development endeavors to enhance the efficiency and functionality of ultrasonic transducers is further propelling market growth. To summarize, the industrial ultrasonic transducer market is observing significant advancement driven by elements like escalating demand across varied industries, increased adoption for non-destructive testing, technological progressions, focus on energy efficiency, and amplified investments in research and development efforts.

Restraining Factors:

The market expansion is hindered by the scarcity of proficient technicians and the substantial expenses linked to the deployment of industrial ultrasonic transducers.

The market for industrial ultrasonic transducers is on the brink of advancement but faces notable challenges. One significant obstacle is the high cost involved in acquiring these transducers, attributed to the utilization of sophisticated technology and components that elevate production expenses in comparison to traditional alternatives. Another deterrent is the limited understanding and recognition of the advantages and applications of ultrasonic transducers within various industries, resulting in a restrained uptake. Furthermore, the proficiency required to effectively operate ultrasonic transducers creates a barrier to adoption, necessitating specialized training and expertise. Stringent regulations and standards governing the use of ultrasonic transducers in different sectors also pose complexities and increased compliance costs for manufacturers, potentially impeding market growth. Nevertheless, despite these obstacles, the industrial ultrasonic transducer market exhibits substantial growth potential. The increasing demand for non-destructive testing, cleaning, and detection solutions in sectors like healthcare, automotive, and manufacturing, along with technological advancements and a focus on efficiency, are projected to drive market expansion. Educating industries on the benefits of ultrasonic transducers and enhancing training initiatives can mitigate challenges associated with awareness and proficiency. Through ongoing innovation and progress, the industrial ultrasonic transducer market is poised to thrive, transforming industries, enhancing productivity, and elevating quality standards.

Key Segments of the Industrial Ultrasonic Transducer Market

Type Overview

• Contact Transducer

• Dual Element Transducer

• Immersion Transducer

• Shear Wave Transducer

• Delay Line Transducer

Application Overview

• Level and Measurement

• NDT (Non-Destructive Testing)

• Production Process Control

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America