Market Analysis and Insights:

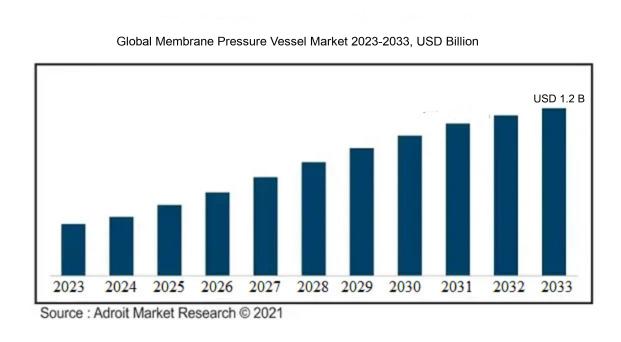

The market for Global Membrane Pressure Vessel was estimated to be worth USD 0.8 billion in 2023, and from 2024 to 2033, it is anticipated to grow at a CAGR of 7%, with an expected value of USD 1.2 billion in 2033.

The Membrane Pressure Vessel Market is driven by a multitude of significant factors. A critical aspect is the soaring demand for water treatment and desalination methods, spurred by the pressing issue of global water shortages, which necessitates the implementation of effective membrane technologies and stimulates market expansion. Furthermore, stringent environmental regulations compel industries to seek advanced water purification options, highlighting the crucial role of membrane pressure vessels. Innovations in membrane materials and design significantly improve the efficiency and durability of these vessels, attracting increased investment in research and development. Additionally, the growing emphasis on sustainable practices is leading to wider adoption of membrane separation technologies across diverse industries, such as pharmaceuticals, food and beverage, and oil and gas. The rising population and urban development also exacerbate the demand for clean water, thereby positively influencing the need for membrane pressure vessels. Collectively, these dynamics foster a fertile environment for the ongoing growth of the membrane pressure vessel market.

Membrane Pressure Vessel Market Scope :

| Metrics | Details |

| Base Year | 2024 |

| Historic Data | 2020-2023 |

| Forecast Period | 2024-2033 |

| Study Period | 2023-2033 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2033 | USD 1.2 billion |

| Growth Rate | CAGR of 7% during 2024-2033 |

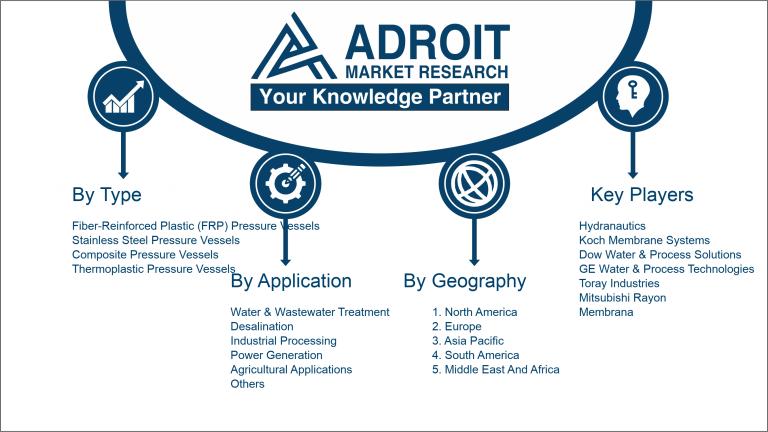

| Segment Covered | By Type, By Application, By Distribution Channel, Regions |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Hydranautics, Koch Membrane Systems, Dow Water & Process Solutions, GE Water & Process Technologies, Toray Industries, Mitsubishi Rayon, Membrana, Pall Corporation, SUEZ Water Technologies & Solutions, and Pentair. Additional noteworthy firms include Berghof Membranes, DONGYANG FILTER, Axium Process, TriSep Corporation, and Linde PLC. |

Market Definition

A membranous pressure vessel is a specialized container engineered to store gases or liquids at elevated pressures, leveraging slender, adaptable membranes to endure internal forces. Such vessels find frequent application in scenarios where minimizing weight and maximizing structural effectiveness are vital considerations.

Pressure vessels with membranes are vital in numerous industrial sectors, especially within water purification and desalination efforts. They employ semi-permeable membranes to effectively isolate impurities from water, thereby boosting the efficiency of the purification process. Constructed to endure high-pressure conditions, these vessels guarantee superior functionality during reverse osmosis or nanofiltration procedures. Their significance is underscored by their capacity to deliver safe, potable water while tackling environmental issues associated with wastewater treatment. Additionally, innovations in membrane technology have resulted in enhanced resilience and reduced operational expenses, positioning them as key components for sustainable resource management and meeting the worldwide need for clean water.

Key Market Segmentation:

Insights On Key Type

Fiber-Reinforced Plastic (FRP) Pressure Vessels

The dominating in the Global Membrane Pressure Vessel Market is the Fiber-Reinforced Plastic (FRP) Pressure Vessels. This is primarily due to their lightweight nature and high resistance to corrosion, making them ideal for various applications such as water treatment and oil & gas. Furthermore, FRP vessels possess excellent chemical compatibility and high strength-to-weight ratios, leading to increased efficiency and cost-effectiveness in long-term operations. The growing emphasis on sustainable materials and lightweight design across industries will further propel the demand for FRP vessels, solidifying their leading position in the market.

Stainless Steel Pressure Vessels

Stainless Steel Pressure Vessels are favored for their durability and resistance to corrosion and high temperatures. This makes them an excellent choice for industries that require stringent sanitation standards, such as the food and beverage industry and pharmaceuticals. Moreover, their robust mechanical properties allow them to withstand extreme conditions, thereby ensuring consistent performance. These vessels also have a long lifespan, reducing the need for frequent replacements, which is advantageous for businesses looking to minimize operational costs.

Composite Pressure Vessels

Composite Pressure Vessels are made from a combination of materials that aid in minimizing weight while maintaining structural integrity. Their unique construction allows them to withstand higher pressures compared to traditional materials, making them suitable for specialized applications such as aerospace and high-performance automotive industries. The lightweight nature of composites can lead to significant efficiencies in energy usage and transportation costs, making them increasingly attractive for applications where weight-saving is critical. However, the higher upfront cost tends to limit their widespread adoption compared to other materials.

Thermoplastic Pressure Vessels

Thermoplastic Pressure Vessels are recognized for their easy processing and recyclability, which contribute to reduced environmental impact. These vessels can provide significant flexibility in design and can be manufactured in various shapes and sizes to meet specific needs. They are generally less robust than metal alternatives but are gaining traction in applications that prioritize chemical resistance and lower weight. Their growing use in industrial processes where corrosive materials are handled underscores their increasing relevance as industries seek sustainable and innovative materials for their operations.

Insights On Key Application

Water & Wastewater Treatment

The Water & Wastewater Treatment category is expected to dominate the Global Membrane Pressure Vessel Market. This is primarily due to the rising global demand for clean drinking water and the increasing need for efficient treatment solutions for wastewater management. With urbanization and industrial growth, municipalities and industries are investing significantly in modern water treatment technologies. Membrane pressure vessels play a crucial role in processes like reverse osmosis and microfiltration, which are essential for both water purification and effluent treatment. As environmental regulations become stricter, the focus on sustainable water management practices further enhances the relevance of this application in the market.

Desalination

Desalination is an important area in the membrane pressure vessel market, particularly in water-scarce regions. The demand for fresh water in arid areas leads to the implementation of desalination techniques, where seawater is treated to produce potable water. Governments and companies are increasingly investing in desalination plants, driving growth in this sector. While it may not dominate like Water & Wastewater Treatment, its significant contribution, especially in developing nations, is notable due to the necessity for sustainable water resources.

Industrial Processing

The Industrial Processing application is a critical component of the membrane pressure vessel market. Industries such as food and beverage, pharmaceuticals, and chemical processing require high-purity water and efficient separation processes. Membrane pressure vessels are vital for these applications, enabling effective filtration and concentration processes. The growing demand for process optimization and productivity improvements in various sectors continues to support the adoption of membrane technologies.

Power Generation

Power Generation applications in the membrane pressure vessel market have a specific role, particularly in cooling water treatment and boiler feed water treatment. The need for efficient operation and reduced environmental impacts drives the adoption of membrane technologies in energy production facilities. As the industry seeks to integrate more sustainable practices and reduce water waste, the integration of membrane systems in new power projects becomes increasingly relevant.

Agricultural Applications

Agricultural Applications represent a growing area in the membrane pressure vessel market, focusing on improving irrigation efficiency and water recycling. Given the increasing need for sustainable farming practices and water conservation, farmers are adopting advanced membrane technologies for applications such as fertigation and water purification. However, this is still emerging when compared to the dominant Water & Wastewater Treatment category but will likely grow as global food demands rise and climate change impacts water availability.

Others

The Others category consists of miscellaneous applications that utilize membrane pressure vessels, including aquaculture, semiconductor manufacturing, and others. While this sector does see usage of membrane technologies, it holds a smaller share of the market when compared to the major applications discussed above. Innovations and niche applications may drive growth in this area, but its overall impact is lesser in magnitude, making it not a leading category in terms of market dynamics.

Insights On Key Distribution Channel

Online Platforms

The Online Platforms channel is expected to dominate the Global Membrane Pressure Vessel Market due to the increasing trend of digital transformation across industries. The rapid growth of e-commerce has facilitated easy access to products and has empowered manufacturers and customers to connect seamlessly. Buyers prefer the convenience, diverse options, and competitive pricing that online marketplaces offer, resulting in higher sales volumes. Furthermore, the ability to gather customer insights through online channels allows companies to tailor their offerings more effectively, enhancing customer satisfaction and loyalty. Thus, the Online Platforms channel will likely take the lead in this market.

Direct Sales

Direct Sales remain a crucial method for connecting manufacturers directly with customers. This approach fosters strong relationships, enables tailored solutions, and facilitates rapid response to customer needs. While it may not match the convenience of online shopping, direct sales provide personalized services, which are essential in technical markets like membrane pressure vessels. Companies relying on direct sales often establish credibility and trust with customers, serving niche sectors that prioritize reliability and specialist knowledge over price alone.

Distributors and Wholesalers

Distributors and Wholesalers play a significant role in the Global Membrane Pressure Vessel Market by bridging the gap between manufacturers and end-users. They are pivotal in ensuring that products reach a wider audience and can maintain effective inventory levels, which is crucial for industries requiring immediate availability of such specialized equipment. Their established networks and experience in market logistics lead to increased efficiency in product distribution. However, the impact of digital channels may weaken their dominance in the long term as buyers increasingly seek direct access to suppliers.

Engineering, Procurement, and Construction (EPC) Firms

EPC Firms are essential players in the membrane pressure vessel market, particularly in large-scale projects that require specialized equipment tailored to specific applications. These firms have an in-depth understanding of project needs and can negotiate bulk purchases, often leading to cost savings. However, their dependency on specific project timelines may limit their overall market presence compared to more agile distribution channels. The role of EPC companies, while significant, is primarily project-driven and may not compete with the flexibility offered by online platforms or direct sales in an evolving marketplace.

Aftermarket Services Providers

Aftermarket Services Providers focus on maintenance, repairs, and replacements, which are integral to sustaining the lifecycle of membrane pressure vessels. Though crucial post-purchase, their role is reactive rather than proactive, limiting their market reach compared to other distribution avenues. Their significant revenue often stems from service contracts and parts sales, indicating that while they provide essential support, they do not dominate the sales aspect of the market. Establishing partnerships can enhance their visibility, but they must compete with more direct sales and distribution methods to grow effectively.

Specialty Retailers

Specialty Retailers cater to niche markets that require specific membrane pressure vessel products. While they focus on a targeted audience and offer expert advice tailored to unique applications, they face limitations in comparison to wider-reaching sales channels like online platforms. Their market penetration can be limited due to a smaller customer base, making it challenging to compete in terms of pricing and variety. Nevertheless, they can thrive by maintaining high service quality and specialized knowledge, appealing to customers seeking personalized assistance and specific product offerings.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is poised to dominate the Global Membrane Pressure Vessel market due to significant industrial growth, increasing urbanization, and rising investments in water treatment and desalination projects. Countries like China and India are investing heavily in infrastructure development, which, in turn, boosts demand for membrane technologies. Furthermore, the region's rapid industrialization is leading to ened requirements for sustainable solutions in various applications, including wastewater management and food processing. This burgeoning demand is coupled with government support for environment-friendly technologies and initiatives, creating a favorable environment for growth in membrane pressure vessel applications across multiple industries.

North America

North America presents a promising market for membrane pressure vessels, primarily driven by advanced technological innovations and stringent environmental regulations. The U.S. and Canada are at the forefront of adopting membrane separation technologies, emphasizing sustainability and water conservation. Additionally, a growing focus on efficient wastewater treatment facilities in urban areas, coupled with flourishing industries such as pharmaceuticals and food processing, is expected to drive demand in this region significantly. However, competition with Asia Pacific may hinder North America from becoming the leading market.

Europe

Europe's market for membrane pressure vessels is characterized by robust regulatory frameworks and a strong emphasis on green technologies. European countries are making concerted efforts to enhance water quality and minimize industrial waste, which boosts the adoption of membrane technologies. Furthermore, a significant focus on research and development fosters innovation in membrane materials and designs, ensuring that Europe remains a key player in advanced water treatment solutions. However, the high cost associated with advanced membrane systems might limit rapid market expansion compared to the Asia Pacific.

Latin America

Latin America is gradually emerging in the membrane pressure vessel market, driven by increasing awareness and efforts towards water management and sustainable practices. Governments across the region are investing in water infrastructure projects to tackle challenges related to water scarcity and pollution. Although the market is growing, it still faces barriers such as economic instability and limited access to advanced technologies. Regional players are also beginning to collaborate with international firms to enhance their capabilities and meet domestic market needs more effectively in the coming years.

Middle East & Africa

The Middle East & Africa region holds growth potential within the membrane pressure vessel market, particularly due to the pressing need for water desalination solutions driven by arid climates and water scarcity challenges. Several countries in the Middle East are implementing extensive desalination projects to meet the growing water demand. Additionally, there is an increasing commitment towards industrial water treatment initiatives. However, investment in infrastructure and technological advancements is still in its infancy compared to more developed regions, indicating that this market has significant room for future growth and development.

Company Profiles:

Leading entities within the Global Membrane Pressure Vessel sector are at the forefront of innovation and enhancing production efficacy, concentrating on cutting-edge filtration technologies to improve functionality. Their strategic partnerships and funding in research and development are crucial for meeting various industrial requirements and broadening their market presence.

Prominent entities within the Membrane Pressure Vessel Market consist of Hydranautics, Koch Membrane Systems, Dow Water & Process Solutions, GE Water & Process Technologies, Toray Industries, Mitsubishi Rayon, Membrana, Pall Corporation, SUEZ Water Technologies & Solutions, and Pentair. Additional noteworthy firms include Berghof Membranes, DONGYANG FILTER, Axium Process, TriSep Corporation, and Linde PLC. Furthermore, companies like Process Water Treatment, Alfa Laval, and CSM Membrane Technologies play a significant role in shaping the market environment.

COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly impacted the Global Membrane Pressure Vessel market, resulting in supply chain disruptions and diminished demand in numerous sectors. This situation caused project delays and fostered a transition towards automation and remote monitoring solutions.

The membrane pressure vessel market underwent substantial changes due to the COVID-19 pandemic, which caused widespread disruptions across multiple sectors. Initially, various lockdown protocols and interruptions in global supply chains resulted in manufacturing delays and shortages of essential raw materials, leading to a decrease in production output. Demand for membrane pressure vessels varied, largely influenced by a decline in industrial operations and postponed initiatives, particularly within water treatment, chemicals, and the food and beverage industries. However, the pandemic underscored the critical need for effective filtration and separation technologies, fostering a renewed emphasis on sustainable practices and improved water management strategies. As industries adjust to the evolving landscape, the market is projected to recover, bolstered by growing investments in infrastructure and ened environmental awareness. In the future, the adoption of advanced technologies and a stronger focus on health and safety measures are expected to influence the trajectory of the membrane pressure vessel market in the post-pandemic era.

Latest Trends and Innovation:

- In October 2021, Dow Water & Process Solutions, a business unit of Dow Inc., announced the launch of its new high-performance membrane technology aimed at improving water filtration efficiency, which is expected to enhance the membrane pressure vessel market significantly.

- In February 2022, Siemens Water Technologies acquired the water and wastewater treatment division of a leading membrane manufacturer, further strengthening its portfolio and capabilities in membrane pressure vessel solutions.

- In January 2023, Hydranautics, part of the Nitto Group, revealed a new line of reverse osmosis membranes specifically designed for use in pressure vessels, targeting industries with high demand for purity and performance in water treatment.

- In July 2023, Pentair plc completed the acquisition of a membrane manufacturing company, which enables them to enhance their production capabilities and expand their offerings in the membrane pressure vessel market for industrial applications.

- In September 2023, Toray Industries, Inc. announced a breakthrough in polymer technology that significantly improves the performance of their reverse osmosis membranes, optimizing water filtration processes and expanding their market share in membrane pressure vessels.

Significant Growth Factors:

The market for Membrane Pressure Vessels is experiencing growth driven by a ened need for effective water treatment options, innovations in membrane technology, and a growing array of industrial uses.

The Membrane Pressure Vessel Market is undergoing remarkable expansion, attributed to several pivotal elements. Firstly, the surging need for effective water purification technologies in residential, industrial, and municipal applications is driving the demand for advanced membrane solutions. Enhanced global emphasis on sustainable water management and stricter regulatory measures aimed at minimizing water pollutants further fuel this market's growth. Innovations in membrane materials, particularly the introduction of thin-film composite membranes, significantly improve both performance and durability, attracting substantial investments.

Moreover, the burgeoning food and beverage sector relies heavily on membrane filtration for ensuring product safety and clarity, thereby increasing demand. The rise in industrial uses, notably in pharmaceuticals and chemical processes where accurate filtration is essential, also plays a crucial role in this market's development. Additionally, the movement towards decentralized water treatment systems, especially in developing nations grappling with water shortages, drives the implementation of membrane pressure vessels. Growing awareness of environmental challenges and the urgent need for energy-efficient filtration techniques inject further momentum into this sector. All these factors contribute to a robust environment for the Membrane Pressure Vessel Market, establishing its importance in contemporary water treatment innovations.

Restraining Factors:

The Membrane Pressure Vessel Market faces significant barriers due to elevated upfront investment expenses and rigorous regulatory standards that must be met.

The Membrane Pressure Vessel Market encounters a variety of challenges that could impede its growth potential. A primary obstacle is the substantial investment required for the production and installation of these vessels, which may discourage potential investors and restrict market entry, particularly in emerging economies. Furthermore, rapid technological advancements demand ongoing financial commitment to research and development, presenting significant challenges for smaller enterprises. Compliance with regulatory standards can serve as an additional hurdle, as stringent requirements related to material safety and performance often complicate the approval processes for new innovations.

Additionally, the market faces competition from alternative separation technologies that tout lower operational costs and enhanced efficiency, potentially impacting the adoption rates of membrane pressure vessels. Concerns regarding the environmental footprint and disposal of used membranes further contribute to stakeholder apprehension. Nevertheless, the increasing demand for sustainable and effective water treatment solutions opens up opportunities for innovation, motivating manufacturers to create advanced membrane technologies capable of addressing these challenges. Thus, while it is crucial to acknowledge the various restraining factors, the Membrane Pressure Vessel Market still holds considerable promise for growth and innovation.

Key Segments of the Membrane Pressure Vessel Market

By Type

• Fiber-Reinforced Plastic (FRP) Pressure Vessels

• Stainless Steel Pressure Vessels

• Composite Pressure Vessels

• Thermoplastic Pressure Vessels

By Application

• Water & Wastewater Treatment

• Desalination

• Industrial Processing

• Power Generation

• Agricultural Applications

• Others

By Distribution Channel

• Direct Sales

• Distributors and Wholesalers

• Online Platforms

• Engineering, Procurement, and Construction (EPC) Firms

• Aftermarket Services Providers

• Specialty Retailers

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America