Market Analysis and Insights:

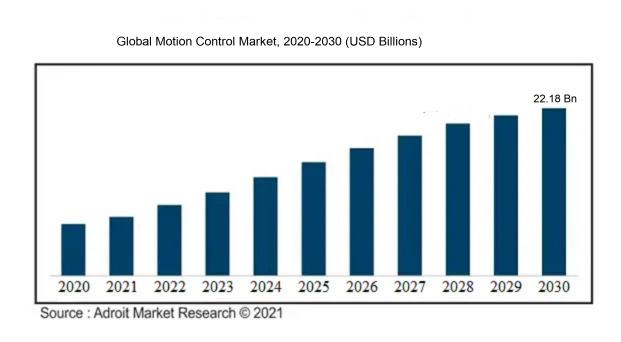

The market for Global Motion Control was estimated to be worth USD 15.31 billion in 2023, and from 2024 to 2030, it is anticipated to grow at a CAGR of 5.79%, with an expected value of USD 22.18 billion in 2030.

The growth trajectory of the motion control market is being influenced by multiple factors. An important driver is the rising adoption of automation in industries like automotive, aerospace, and manufacturing, which is creating a demand for precise motion control systems essential for the accurate operation of industrial equipment. Moreover, technological advancements, including the integration of motion control with Internet of Things (IoT) and artificial intelligence (AI), are contributing to market expansion. Increased efficiency and productivity in industrial processes are also key driving forces, with motion control systems offering enhanced accuracy, speed, and reliability. Additionally, the market is being propelled by the increasing demand for robotics and industrial automation, as the integration of motion control systems in robotics enables better control and coordination, leading to improved performance and productivity. Overall, the motion control market is poised for significant growth as industries diversify their applications and embrace automation and advanced technology at a higher rate.

Motion Control Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2030 |

| Study Period | 2018-2030 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2030 | USD 22.18 billion |

| Growth Rate | CAGR of 5.79% during 2024-2030 |

| Segment Covered | By Application, By System, By Offering, By End-User Industry, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | ABB Ltd., Rockwell Automation Inc., Schneider Electric SE, Mitsubishi Electric Corporation, Bosch Rexroth AG, Siemens AG, Yaskawa Electric Corporation, Parker Hannifin Corporation, Omron Corporation, and Emerson Electric Co. |

Market Definition

Motion control encompasses the innovative technology and methodologies employed to govern and oversee the motion of machinery or systems with precision and a high degree of control. By optimizing efficiency and precision across a spectrum of industrial settings, this discipline leverages a combination of sensors, actuators, and control algorithms to attain specific motion objectives.

Motion control holds significant importance across various industries and applications as it facilitates the regulation and manipulation of mechanical system movements. The integration of motion control technology offers businesses the opportunity to enhance efficiency, accuracy, and productivity. Through this technology, precise management of speed, position, and synchronization of movements within intricate systems becomes achievable, thereby improving performance and reducing errors. Industries such as manufacturing, robotics, aerospace, and automotive sectors heavily rely on motion control systems due to the critical impact even slight deviations can have. Ultimately, motion control serves as a fundamental element in optimizing operational effectiveness and ensuring peak performance in a diverse array of applications, solidifying its vital role in today's dynamic technological landscape.

Key Market Segmentation:

Insights On Key Application

Metal Cutting

Metal cutting is expected to dominate the Global Motion Control Market due to the significant demand for precision cutting processes in various industries such as automotive, aerospace, and manufacturing. Motion control systems are crucial for achieving high levels of accuracy and efficiency in metal cutting applications. These systems provide precise control over the cutting tools, allowing for complex and intricate cuts to be made with ease. The growth of industries that heavily rely on metal cutting processes, coupled with advancements in motion control technology, will drive the dominance of this part in the global market.

Metal Forming

Metal forming is another important application within the Global Motion Control Market. It involves various processes such as bending, stretching, and punching of metal sheets or components to create desired shapes and structures. Motion control systems play a crucial role in enabling precise control over the metal forming processes, ensuring consistent results and high-quality output. Although metal forming is expected to have a significant market share, it is likely to be overshadowed by the dominant part of metal cutting due to the higher demand and technological advancements associated with cutting processes.

Material Handling

Material handling is an integral application of industries such as logistics, warehousing, and manufacturing, making it a significant part in the Global Motion Control Market. Motion control systems are used to automate material handling tasks, including conveying, sorting, and packaging. These systems improve operational efficiency, reduce manual labor, and ensure accurate and timely movement of materials. While material handling is expected to contribute a considerable share to the market, it may not dominate over metal cutting and metal forming due to the higher demand and advancements in these sectors.

Packaging

Packaging is another application within the Global Motion Control Market that plays a crucial role in industries such as food and beverage, pharmaceuticals, and consumer goods. Motion control systems are used to automate packaging processes, including filling, sealing, labeling, and palletizing. These systems enable precise control and synchronization of packaging machinery, ensuring efficient and error-free packaging operations. Although packaging is expected to have its share in the market, it may not dominate as metal cutting and metal forming applications are more prevalent and technologically advanced.

Robotics

Robotics is a rapidly growing application within the Global Motion Control Market. With the increasing adoption of industrial robots in various industries, motion control plays a vital role in enabling precise and controlled movement of robots. Motion control systems provide the necessary control algorithms and feedback mechanisms to ensure accurate positioning, path planning, and coordinated motion of robotic arms and other robotic components. While robotics is expected to contribute significantly to the market, it may not dominate over metal cutting due to the widespread usage and advancements in metal cutting applications.

Others

The Others category encompasses various smaller applications within the Global Motion Control Market. These applications can include niche industries or specific processes that utilize motion control systems to achieve precise and controlled movement. While these applications may have their importance, they are likely to have a relatively smaller share in the overall market compared to the dominant parts such as metal cutting, metal forming, material handling, packaging, and robotics. The dominance of these larger and more established parts is expected to limit the market share of the "Others" category.

Insights On Key System

Closed-loop

Closed-loop is expected to dominate the Global Motion Control market. This part utilizes a feedback mechanism that continuously monitors the output and adjusts the input accordingly to maintain precise control of motion. It offers superior accuracy, stability, and reliability compared to open-loop systems. Industries with strict performance demands such as aerospace, automotive, and robotics often prefer closed-loop systems for their ability to handle complex and high-precision applications. The closed-loop part's advanced control capabilities make it highly suitable for tasks involving position, velocity, and torque control. With its ability to provide improved performance and ensure system integrity, the closed-loop part is anticipated to hold a dominant position in the Global Motion Control market.

Open-loop

Open-loop systems, while widely used in various applications, are not expected to dominate the Global Motion Control market. This part operates without a feedback mechanism, relying solely on predetermined inputs to control the motion. It is often utilized in simpler tasks that require less precision and do not necessitate continuous adjustments. Open-loop systems are commonly found in applications such as conveyor belts, simple assembly lines, and basic industrial processes. However, due to their lack of feedback and potential for inaccuracies and drift, open-loop systems may not be suitable for tasks that require high precision and reliability. Therefore, while open-loop systems have their place in certain applications, they are not expected to dominate the overall Motion Control market.

Insights On Key Offering

Hardware

The Hardware offering is expected to dominate the Global Motion Control Market. Hardware encompasses various components like motors, drives, sensors, and mechanical systems that are essential for motion control systems. As the demand for automation and robotics continues to rise across industries such as manufacturing, automotive, and aerospace, the need for reliable and efficient hardware solutions also increases. With advancements in technology, the development of more advanced and precise hardware components has become crucial for achieving high-performance motion control systems. As a result, the Hardware part is projected to dominate the market due to its integral role in supporting motion control applications.

Actuators and Mechanical Systems

Actuators and Mechanical Systems are vital components in motion control systems, responsible for converting energy into physical motion. While the Hardware part is expected to dominate the Global Motion Control Market, the Actuators and Mechanical Systems part play a crucial role in facilitating this dominance. Actuators, such as motors and hydraulic/pneumatic systems, provide the necessary force for motion control applications. Mechanical systems, including gears, belts, and linkages, ensure precise movement and positioning. The Actuators and Mechanical Systems part's significance lies in its contribution to overall system performance, accuracy, and reliability, supporting the dominant Hardware part.

Drives

As player of the broader Hardware sector, Drives are expected to play a crucial role in the Global Motion Control Market. Drives are devices that control the speed, torque, and direction of the motion control system's actuators. They provide the necessary electrical power and signals to drive motors and other mechanical components efficiently. Drives come in different forms, such as servo drives, variable frequency drives, and stepper motor drives, catering to various motion control applications. With the increasing adoption of automation and robotics across multiple industries, the demand for drives to support precise and synchronized motion control systems is anticipated to rise, contributing to the dominance of this part within the Hardware category.

Motors

Motors, a player of the Hardware category, are essential components that generate motion in motion control systems. As the dominant part, motors play a critical role in driving and controlling physical movement. Motors can be classified into different types, including servo motors, stepper motors, and AC/DC motors, each suitable for specific application requirements. The growing need for precise positioning, speed control, and synchronization in various industries drives the demand for high-performance motors, contributing to their dominance within the Global Motion Control Market's Hardware part.

Motion Controllers

Motion Controllers form a significant player under the Hardware category in the Global Motion Control Market. These devices coordinate, monitor, and control multiple actuators and mechanical systems within a motion control system. Motion controllers receive input signals from sensors and feedback devices, process the information, and generate control signals to achieve desired motion dynamics. As industries increasingly embrace automation and robotics, motion controllers facilitate sophisticated control algorithms, enabling precise and coordinated movement. With the demand for intelligent and adaptable motion control systems expected to rise, motion controllers are anticipated to remain vital components within the Hardware part.

Sensors and Feedback Devices

While the Hardware sector is expected to dominate the Global Motion Control Market, the Sensors and Feedback Devices part plays a crucial role in supporting its overall performance. Sensors and feedback devices provide real-time data on various parameters such as position, velocity, and acceleration to ensure accurate and responsive motion control. These devices contribute to improved system stability, precision, and safety. Sensor technologies like encoders, accelerometers, and proximity sensors enable feedback control and enhance the capabilities of motion control systems. Although not the dominant part, Sensors and Feedback Devices have a significant impact on the overall effectiveness and reliability of motion control applications.

Software and Services

The Software and Services player, although not expected to dominate the Global Motion Control Market, plays a complementary role in enhancing the overall performance and functionality of motion control systems. Software solutions provide programming and configuration tools for motion controllers, enabling customization and optimization of control algorithms. Additionally, software packages offer monitoring, diagnostics, and analytics capabilities for motion control systems, facilitating predictive maintenance and process optimization. Services include technical support, training, and system integration expertise that assist customers in deploying and utilizing motion control technology effectively. While not the dominant part, Software and Services play a crucial role in enabling seamless operation, optimization, and maintenance of motion control systems in various industries.

Insights On Key End-User Industry

Aerospace

The aerospace industry is expected to dominate the global motion control market. This is primarily due to the increasing demand for advanced motion control systems in aircraft and spacecraft manufacturing. Aerospace companies require precise and efficient motion control solutions to enhance aircraft performance, improve safety, and reduce maintenance costs. With ongoing advancements in the aerospace sector, such as the development of unmanned aerial vehicles (UAVs) and electric aircraft, the demand for motion control systems is anticipated to grow significantly. Furthermore, strict regulatory standards for aircraft safety and reliability also drive the adoption of motion control technologies in the aerospace industry.

Automotive

The automotive industry is another significant sector in the global motion control market. Manufacturers in the automotive sector rely on motion control systems for various applications, including robotics, assembly lines, and automated guided vehicles (AGVs). With the increasing demand for electric vehicles (EVs) and autonomous driving technologies, the automotive industry has witnessed a surge in the adoption of motion control systems. These systems help in improving vehicle performance, enhancing fuel efficiency, and achieving precise control for various automotive processes.

Semiconductor & Electronics

The semiconductor and electronics industry is expected to play a crucial role in the global motion control market. Motion control systems are vital for precise and accurate movements in semiconductor and electronics manufacturing processes. These systems are utilized in robots, pick-and-place machines, and inspection systems to ensure efficient production and quality control. The increasing demand for electronic devices, growth in the semiconductor industry, and automation of manufacturing processes contribute to the dominance of the semiconductor and electronics part in the motion control market.

Metals & Machinery

The metals and machinery industry is another important player within the global motion control market. Motion control systems are utilized in various applications in this industry, including material handling, machine tools, and metal cutting equipment. These systems enable efficient operations, minimize downtime, and enhance productivity in metalworking and machinery processes. With the rising demand for metal products and industrial machinery, the metals and machinery part is expected to hold a significant share in the motion control market.

Food & Beverages

The food and beverages industry is an emerging player in the global motion control market. Motion control systems find applications in food processing, packaging, and bottling lines to maintain precision and speed. With the increasing focus on food safety, product quality, and operational efficiency, the adoption of motion control systems in the food and beverages sector is expected to grow. These systems offer benefits such as improved production accuracy, reduced wastage, and enhanced line efficiency.

Medical Devices

The medical devices industry is witnessing significant growth and is expected to be a key component in the motion control market. Motion control systems are used in medical devices like surgical robots, imaging equipment, and prosthetics, where precise and accurate movements are vital. The continuously evolving medical technology landscape and the demand for advanced, minimally invasive procedures drive the adoption of motion control systems in the medical devices industry.

Printing & Paper

The printing and paper industry is also a player in the motion control market. Motion control systems are employed in printing presses, paper cutting machines, and packaging equipment to ensure precise movement and consistent quality. As the printing industry transitions toward digital printing and automated processes, the demand for motion control systems is expected to increase to meet the requirements of high-quality output and operational efficiency.

Pharmaceuticals & Cosmetics

The pharmaceuticals and cosmetics industry is a niche player within the motion control market. Motion control systems find applications in pharmaceutical manufacturing processes, such as precision dosing, liquid handling, and packaging. In the cosmetics industry, these systems are used for automated filling, labeling, and packaging of products. As the demand for personalized medicine and cosmetic products grows, the adoption of motion control systems in the pharmaceuticals and cosmetics sector is expected to rise.

Other Industries

Other industries encompass various sectors that may have limited representation in the motion control market compared to the dominant parts mentioned above. These industries could include sectors such as textiles, chemicals, renewable energy, and logistics. While the demand for motion control systems may exist in these industries, it is anticipated to be relatively smaller compared to the dominating parts, as their specific processes may not heavily rely on motion control technologies.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the global motion control market. The region has a strong presence of industries such as automotive, manufacturing, and food and beverage, which are key consumers of motion control systems. Additionally, the rapid industrialization and increasing investments in automation technologies in countries like China, Japan, South Korea, and India are driving the demand for motion control solutions. The region is also witnessing a surge in the adoption of robotics and industrial automation, further boosting the demand for motion control systems. Moreover, the availability of skilled labor and favorable government initiatives to promote industrial automation are supporting the growth of the motion control market in Asia Pacific.

North America

North America is a significant player in the global motion control market. The region is a hub for technologically advanced industries, including aerospace, defense, and automotive, which extensively use motion control systems. The presence of major market players and continual innovation in automation technologies also contribute to the dominance of North America in the motion control market. Moreover, the growing demand for robotics in various industries and the rising adoption of Industry 4.0 principles are expected to drive the market further in the region.

Europe

Europe is another prominent region in the global motion control market. The region has a well-established industrial base and a high degree of automation in industries such as automotive, pharmaceuticals, and food and beverage. The emphasis on increasing productivity, reducing operational costs, and ensuring product quality has led to the widespread adoption of motion control systems in Europe. Additionally, the region is characterized by strong government support, favorable regulations, and partnerships between research organizations and industry players, fostering innovation and technological advancements in motion control. These factors contribute to Europe's dominance in the global motion control market.

Latin America

Latin America is an emerging region in the global motion control market. The region is witnessing an increasing adoption of automation technologies in industries such as automotive, manufacturing, and packaging. The growing investments in infrastructure development and the rising demand for labor-saving technologies drive the demand for motion control systems in Latin America. Furthermore, the region's favorable government initiatives and the growing awareness about the benefits of motion control systems contribute to its market growth.

Middle East & Africa

The Middle East & Africa region holds a smaller share in the global motion control market compared to the aforementioned regions. However, the region is witnessing growth in the adoption of industrial automation and robotics in sectors such as oil and gas, manufacturing, and logistics. The increasing focus on modernizing industries for enhancing productivity and efficiency is expected to drive the demand for motion control systems in the Middle East & Africa.

Additionally, the presence of large-scale infrastructure projects and investments in sectors such as renewable energy and transportation also present opportunities for the growth of the motion control market in the region.

Company Profiles:

Siemens AG is a prominent figure in the international motion control sector, delivering a diverse array of cutting-edge solutions tailored to different industries. These solutions aim to elevate productivity and efficiency levels across various sectors.

Schneider Electric SE, a key player in the global motion control arena, specializes in offering sophisticated motion control systems. These systems facilitate accurate and efficient movement control, empowering industries to streamline their operations and achieve ened performance metrics. Prominent contributors in the field of motion control technology encompass ABB Ltd., Rockwell Automation Inc., Schneider Electric SE, Mitsubishi Electric Corporation, Bosch Rexroth AG, Siemens AG, Yaskawa Electric Corporation, Parker Hannifin Corporation, Omron Corporation, and Emerson Electric Co. These renowned entities are celebrated for their prowess in crafting cutting-edge motion control solutions tailored for a spectrum of industries such as automotive, aerospace, manufacturing, and robotics. By furnishing sophisticated technologies and offerings, they facilitate precise and efficient motion control that elevates the operational efficiency and performance of automated systems and machinery. With a robust market presence, diverse product lines, and a commitment to innovation, these organizations stand out as leading figures within the domain of motion control technology.

COVID-19 Impact and Market Status:

The global motion control market has experienced notable effects from the Covid-19 pandemic, resulting in decreased demand caused by a reduction in industrial operations and disturbances in supply networks.

The impact of the COVID-19 pandemic on the motion control market has been multifaceted. On one hand, disruptions in global supply chains and manufacturing restrictions have led to a decline in the market. Companies have struggled to acquire necessary components, resulting in project delays and reduced operational capacities. Moreover, industries like automotive, aerospace, and manufacturing have experienced sluggish operations, impacting the demand for motion control systems. Conversely, certain sectors such as healthcare, logistics, and e-commerce have seen a rise in the need for motion control technologies. Automation and remote operations have become essential in these industries, prompting increased adoption of motion control systems to enable contactless operations and improve efficiency. In essence, the COVID-19 pandemic has presented a mixture of challenges and opportunities for the motion control market, influencing its growth trajectory in a nuanced manner.

Latest Trends and Innovation:

- In September 2019, Rockwell Automation announced the acquisition of ASEM, a provider of digital automation technologies. This acquisition aimed to enhance Rockwell Automation's portfolio of industrial PCs, human-machine interface software, and secure remote access solutions.

- In October 2019, Parker Hannifin Corporation introduced the ETH Series, a new line of distributed servo drives for the motion control market. These drives are designed to provide flexibility, energy efficiency, and ease of integration into various applications.

- Yaskawa Electric Corporation acquired The Switch, a Finnish manufacturer of electric drives and generators, in February 2020. This acquisition allowed Yaskawa to expand its portfolio and strengthen its position in the renewable energy and marine markets.

- In June 2020, Schneider Electric announced a partnership with Escalent, a human behavior and analytics firm, to conduct a study on the motion control market. The goal of this collaboration was to gain insights into market preferences and trends to better cater to customer needs.

- Siemens AG merged its Digital Industries and Process Industries and Drives divisions in April 2019 to form a new entity called Siemens Digital Industries. This merger aimed to streamline operations and enhance the company's capabilities in the motion control and industrial automation sectors.

- Mitsubishi Electric Corporation introduced the MELSERVO-J5 series of servo amplifiers in February 2021. This new series offers improved performance, safety features, and energy efficiency, catering to the evolving needs of the motion control market.

- In January 2020, ABB Ltd. announced the acquisition of Servomex Group Limited, a global supplier of gas analysis solutions. This strategic acquisition aimed to enhance ABB's portfolio of gas analyzers and strengthen its position in the industrial analytics and motion control sectors.

Significant Growth Factors:

The Motion Control Market is being propelled by key growth drivers such as the growing trend towards automation in various industries and the escalating need for improved precision and efficiency in manufacturing operations.

The motion control sector has seen notable expansion in recent times, primarily propelled by several key factors. A significant driver of this growth is the escalating need for automation and robotics across diverse industries. Companies are increasingly turning to motion control systems to enhance the efficiency, productivity, and precision of their manufacturing operations, given these systems' ability to provide accurate control and synchronization of moving components. Furthermore, the advancement of technologies like 5G, the Internet of Things (IoT), and Artificial Intelligence (AI) has played a pivotal role in fostering the expansion of motion control. These technologies facilitate seamless connectivity, real-time data analysis, and intelligent decision-making, leading to improved performance and reliability of motion control systems.

Additionally, the growing uptake of electric vehicles and renewable energy solutions has driven the demand for motion control within the automotive and energy sectors. The transition to electric propulsion systems and the integration of motion control mechanisms into renewable energy setups have opened up opportunities for market growth. Moreover, the aerospace and defense industry has also made significant contributions to the sector's expansion, as precise movements, stabilization, and safety in aircraft and defense equipment heavily rely on motion control systems. The introduction of Industry 4.0 and smart manufacturing initiatives further propels market growth, given the heavy dependence of these concepts on motion control systems to achieve seamless automation and real-time monitoring. In essence, the flourishing motion control market is a result of various factors, including the increasing demand for automation, technological progress, the adoption of electric vehicles and renewable energy solutions, aerospace and defense applications, and the advent of Industry 4.0 and smart manufacturing strategies.

Restraining Factors:

The increasing intricacy and elevated expenses of motion control systems serve as notable impediments for the motion control industry's growth.

The motion control industry is currently encountering various obstacles that are impeding its expansion. A primary concern is the significant cost associated with implementing motion control technologies, which poses a substantial barrier for many businesses, particularly small and medium-sized enterprises. The initial investment needed for hardware, software, and installation can be prohibitive, hindering companies with financial constraints from fully embracing motion control solutions. Additionally, the shortage of skilled professionals with expertise in motion control technology presents another challenge. The intricate nature of these systems necessitates proficiency in both hardware and software, and the limited availability of qualified personnel can obstruct the deployment and upkeep of motion control systems. Moreover, compatibility issues between different motion control systems offered by various vendors create interoperability limitations that fragment the market. This can present a significant challenge for end-users seeking to integrate multiple systems or upgrade their existing infrastructure.

The COVID-19 pandemic has further exacerbated the situation, causing disruptions in supply chains and reduced industrial activities, which have led to a decreased demand for motion control technologies.

Key Segments of the Motion Control Market

Application Overview

• Metal Cutting

• Metal Forming

• Material Handling

• Packaging

• Robotics

• Others

System Overview

• Open-loop

• Closed-loop

Offering Overview

• Hardware

• Actuators and Mechanical Systems

• Drives

• Motors

• Motion Controllers

• Sensors and Feedback Devices

• Software and Services

End-User Industry Overview

• Aerospace

• Automotive

• Semiconductor & Electronics

• Metals & Machinery

• Food & Beverages

• Medical Devices

• Printing & Paper

• Pharmaceuticals & Cosmetics

• Other Industries

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America