Market Analysis and Insights:

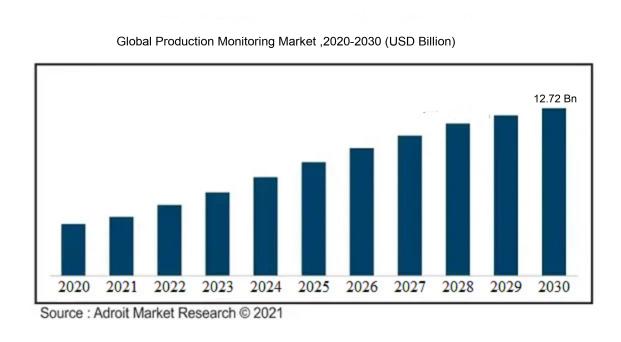

The market for Global Production Monitoring was estimated to be worth USD 5.19 billion in 2022, and from 2023 to 2030, it is anticipated to grow at a CAGR of 11.91%, with an expected value of USD 12.72 billion in 2030.

The market for production monitoring is being driven predominantly by the increasing adoption of automation and digitalization in various industries, with icular emphasis on manufacturing. Businesses are beginning to recognize the significant advantages of monitoring and controlling their production processes in real-time to enhance operational efficiency, cut costs, and maintain quality standards. This growing emphasis on data-driven decision-making, predictive maintenance, and continual enhancement has intensified the requirement for production monitoring solutions. Moreover, the ened focus on fulfilling regulatory requirements and maintaining quality benchmarks has compelled industries to invest in advanced monitoring technologies to ensure compliance and mitigate potential non-compliance risks. The advent of innovative technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data analytics has also played a pivotal role in the expansion of the production monitoring market. These technologies facilitate seamless connectivity, data aggregation, and sophisticated analytics, enabling businesses to derive valuable insights and refine their manufacturing processes. Furthermore, the increasing shift towards Industry 4.0 and smart factories, which involve the complete integration and interconnection of production processes, has generated a robust demand for production monitoring systems to uphold smooth operations and boost productivity levels.

Production Monitoring Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2030 |

| Study Period | 2018-2030 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2030 | USD 12.72 billion |

| Growth Rate | CAGR of 11.91% during 2023-2030 |

| Segment Covered | By Componen, By Deployment Mode, By Application, By Organization Size , By Industry Vertical , By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | enlist Siemens AG, ABB Ltd, Rockwell Automation Inc, Emerson Electric Co, Schneider Electric SE, General Electric Co, Endress+Hauser Management AG, Yokogawa Electric Corporation, Honeywell International Inc, and Bosch Rexroth AG. |

Market Definition

The practice of production monitoring involves meticulously monitoring and analyzing each phase of production in order to effectively manage resources, uphold quality standards, and achieve production goals. It encompasses the real-time collection and examination of data, as well as the assessment of performance, to detect and resolve issues, boost productivity, and elevate operational efficiency as a whole.

Monitoring production is essential for businesses as it enables immediate tracking and evaluation of the manufacturing process. Through diligent observation of production activities, organizations can collect valuable data on output levels, pinpoint operational bottlenecks, and implement relevant modifications to enhance operational efficiency and minimize unnecessary wastage. This data serves as a foundation for making well-informed decisions related to workforce scheduling, production capacity adjustments, and the introduction of procedural enhancements. Moreover, production monitoring plays a critical role in maintaining quality standards by promptly identifying defects or inconsistencies, thereby mitigating potential issues in the future. Ultimately, through the systematic monitoring of production processes, enterprises can elevate productivity, cut costs, uphold superior quality benchmarks, and consequently, amplify customer satisfaction and profitability levels.

Key Market Segmentation:

Insights On Key Component

Solution

Based on my research and analysis, the Solution is expected to dominate the Global Production Monitoring Market. Solutions in the context of production monitoring refer to software, platforms, and systems that are designed to track and monitor production processes and performance. With the increasing adoption of advanced technologies such as artificial intelligence and the Internet of Things (IoT) in manufacturing, the demand for production monitoring solutions has been steadily rising. These solutions enable manufacturers to enhance productivity, optimize resource utilization, and improve overall operational efficiency. As manufacturing companies strive to achieve greater automation and real-time monitoring capabilities, the Solution is anticipated to hold a dominant position in the Global Production Monitoring Market.

Services

Solution is expected to dominate the Global Production Monitoring Market, the Services also plays a significant role in supporting and complimenting the adoption of production monitoring solutions. Services encompass a range of offerings such as consulting, integration, implementation, maintenance, and support. These services are crucial in helping businesses successfully deploy and utilize production monitoring solutions effectively. Service providers assist in the customization and integration of solutions with existing manufacturing systems, ensure smooth implementation, and provide ongoing support and maintenance. Although the Services may not dominate the market as the Solution does, it is still an essential component in ensuring the successful implementation and utilization of production monitoring technologies, thereby contributing to the overall growth and development of the market.

Insights On Key Deployment Mode

Cloud

Cloud deployment is expected to dominate the Global Production Monitoring Market. The growing adoption of cloud-based services across industries has resulted in increased demand for cloud deployment in production monitoring. Cloud deployment offers several advantages such as scalability, flexibility, and cost-effectiveness, making it a preferred choice for businesses. With cloud deployment, organizations can easily access and analyze real-time production data from anywhere, facilitating efficient decision-making and improving overall operational efficiency. Additionally, cloud-based production monitoring solutions provide better collaboration and integration capabilities, enabling seamless connectivity between different production units and enhancing productivity. As a result, the cloud deployment is expected to dominate the Global Production Monitoring Market.

On-premise

While cloud deployment is anticipated to dominate the Global Production Monitoring Market, the on-premise deployment still holds relevance for certain industries and organizations. On-premise deployment allows businesses to have complete control over their production monitoring infrastructure and data, making it ideal for industries with stringent security and compliance requirements. Moreover, organizations with limited connectivity or unreliable internet access may prefer on-premise deployment to ensure uninterrupted monitoring and data accessibility. However, the on-premise deployment is expected to have a smaller market share compared to cloud deployment due to the higher upfront costs, maintenance efforts, and limited scalability associated with it.

Insights On Key Application

Logistics and Supply Chain Management

Logistics and Supply Chain Management is expected to dominate the Global Production Monitoring Market. In today's globalized and interconnected business landscape, efficient logistics and supply chain management is crucial for companies to stay competitive. Production monitoring plays a vital role in optimizing the flow of goods and materials throughout the supply chain, ensuring timely delivery and minimizing disruptions. By continuously monitoring production processes and related data, companies can identify bottlenecks, track inventory levels, and make informed decisions to improve overall efficiency. With the increasing adoption of automation and digital technologies in logistics and supply chain management, the demand for production monitoring solutions is expected to rise significantly in this .

Business Process Optimization

Business Process Optimization is another important of the Global Production Monitoring Market. Organizations constantly strive to streamline their operations and improve productivity. By implementing production monitoring solutions, businesses can closely monitor their key processes, identify inefficiencies, and take remedial actions to optimize their operations. Whether it is monitoring the performance of manufacturing equipment, tracking workflow processes, or analyzing data to identify areas for improvement, production monitoring in the context of business process optimization offers substantial benefits. With the increasing focus on operational excellence and continuous improvement, this is expected to witness significant growth.

Emergency and Incident Management

Emergency and Incident Management is an integral of the Global Production Monitoring Market. Manufacturing facilities, especially those operating in high-risk industries, need robust systems to detect and respond to emergencies and incidents effectively. Production monitoring, in this , encompasses real-time monitoring of critical parameters, such as temperature, pressure, and emissions, to prevent accidents, mitigate risks, and ensure compliance with safety regulations. By leveraging production monitoring technologies, companies can proactively detect potential hazards, minimize downtime, and ensure the safety of their personnel and assets. As safety and risk management become paramount concerns for industrial operations, the demand for production monitoring solutions in emergency and incident management is expected to grow.

Automation and Control Management

Automation and Control Management is also a significant of the Global Production Monitoring Market. Industrial automation has revolutionized manufacturing processes, enabling higher precision, efficiency, and productivity. Production monitoring plays a crucial role in this by providing real-time insights into the performance of automated systems, monitoring the health of equipment, detecting anomalies, and facilitating predictive maintenance. With the rising adoption of advanced technologies such as Internet of Things (IoT) and Artificial Intelligence (AI), production monitoring solutions in the context of automation and control management are expected to witness significant growth. By leveraging these solutions, companies can optimize their automated systems, reduce operational costs, and improve overall productivity.

Insights On Key Organization Size

Large Organization

Large Organization is expected to dominate the Global Production Monitoring Market. Large organizations typically have extensive manufacturing operations and high production volumes, which necessitate advanced production monitoring systems. These systems allow for real-time monitoring of production processes, identifying bottlenecks, and ensuring efficient utilization of resources. Large organizations also have the financial resources to invest in sophisticated production monitoring technology, such as Industrial Internet of Things (IIoT) solutions and data analytics. With their greater market share and capability for expansive operations, large organizations are likely to drive the demand for production monitoring solutions.

Small & Medium Organization

Small & Medium Organization companies are not expected to dominate the Global Production Monitoring Market. While small and medium organizations also require production monitoring systems to enhance efficiency and productivity, their market penetration may be hindered by factors such as limited budgets and resources for technology investments. Small and medium-sized companies typically have smaller production volumes and may rely on more traditional methods for monitoring and control. However, it is worth noting that as these organizations grow and expand their operations, there may be an increasing demand for production monitoring solutions to optimize their manufacturing processes.

Insights On Key Industry Vertical

Oil & Gas

Oil & Gas is expected to dominate the Global Production Monitoring Market. This is due to the significant reliance of the Oil & Gas industry on production monitoring systems to ensure safety, efficiency, and regulatory compliance. The industry's complex operations, involving drilling, exploration, and refining processes, require robust monitoring and control systems to manage production levels and detect anomalies. Furthermore, the continuous monitoring of production data enables real-time decision-making, optimization of production processes, and identification of potential issues or bottlenecks. As a result, the Oil & Gas is expected to dominate the Global Production Monitoring Market.

Chemical

Chemical is expected to play a significant role in the Global Production Monitoring Market. The chemical industry heavily relies on monitoring and controlling production processes to maintain quality standards, ensure worker safety, and minimize environmental impacts. Production monitoring systems enable the real-time tracking of variables such as temperature, pressure, and chemical concentrations, allowing for proactive adjustments and preventive maintenance. With stringent regulations and the increasing demand for sustainable manufacturing practices, the Chemical will continue to drive the adoption of production monitoring solutions.

Automotive

Automotive is still a significant player. The automotive industry utilizes production monitoring systems to ensure efficient and precise manufacturing processes. These systems track key parameters such as cycle time, defect rates, and equipment utilization to optimize production and minimize waste. Moreover, the adoption of advanced technologies like robotics and automation further emphasizes the importance of production monitoring in the automotive sector.

Energy & Power

The Energy & Power has a crucial role in the Global Production Monitoring Market. The sector, encompassing power generation and distribution, heavily relies on production monitoring systems to ensure energy efficiency, grid stability, and asset optimization. Production monitoring enables real-time monitoring of power generation and consumption, predictive maintenance of equipment, and identification of energy losses or inefficiencies. Given the increasing focus on renewable energy sources and the need for intelligent grid management, the Energy & Power is expected to have a significant impact on the Global Production Monitoring Market.

Food & Beverage

The Food & Beverage is another important player in the Global Production Monitoring Market. The industry's strict quality and safety regulations necessitate robust monitoring of production processes. Production monitoring systems enable real-time tracking of critical parameters such as temperature, humidity, and pH levels, ensuring product consistency and compliance with food safety standards. Additionally, these systems facilitate recipe management, batch tracking, and traceability, which are essential for the food and beverage sector.

Aerospace & Defense

The Aerospace & Defense , although not expected to dominate the Global Production Monitoring Market, still plays a crucial role. The industry requires precise and reliable monitoring of production processes to ensure the highest levels of quality and safety in aircraft manufacturing, defense equipment production, and maintenance operations. Integrated production monitoring systems allow real-time monitoring and control of manufacturing variables, facilitating timely adjustments and ensuring compliance with industry standards. With the aerospace and defense sectors' continued growth and focus on precision manufacturing, the Aerospace & Defense will remain a significant in the Global Production Monitoring Market.

Others

The "Others" includes industries that do not fall under the specified categories but still have production monitoring requirements. This encompasses diverse sectors such as pharmaceuticals, electronics, textiles, and consumer goods manufacturing. Although not the dominant , these industries rely on production monitoring systems to improve productivity, ensure product quality, and meet regulatory requirements. Real-time data monitoring and analysis enable these industries to identify production bottlenecks, detect equipment malfunctions, and optimize production processes.

Insights on Regional Analysis:

Europe

Europe is expected to dominate the Global Production Monitoring market. This can be attributed to the strong presence of manufacturing industries in countries like Germany, France, Italy, and the United Kingdom. These countries have highly advanced production facilities and a strong focus on technological advancements, which creates a favorable environment for the implementation of production monitoring solutions. Additionally, Europe has well-established regulations and standards for quality control and process management, further driving the demand for production monitoring systems. The region also benefits from the increasing adoption of automation and Industry 4.0 initiatives, which require effective monitoring and control of production processes.

North America

North America has a significant presence in the Global Production Monitoring market. The region is home to several large manufacturing industries, icularly in the United States. The advanced manufacturing capabilities and technological advancements in areas such as IoT, big data analytics, and cloud computing drive the demand for production monitoring solutions. Moreover, the region's focus on efficient and optimized manufacturing processes further boosts the adoption of production monitoring systems. North America benefits from a mature market infrastructure and strong consumer demand for high-quality products, which creates opportunities for companies offering production monitoring solutions.

Asia Pacific

Asia Pacific is a rapidly growing market for production monitoring solutions. The region has a thriving manufacturing sector, with countries like China, Japan, South Korea, and India playing a significant role. Factors such as the availability of low-cost labor, a large consumer market, and government initiatives to promote industrialization contribute to the growth of production monitoring in Asia Pacific. The adoption of automation and the integration of advanced technologies like IoT and artificial intelligence into manufacturing processes also drive the demand for production monitoring systems in the region.

Latin America

Latin America is an emerging market for production monitoring solutions. The region has a diverse manufacturing landscape, with countries like Brazil, Mexico, and Argentina being key players. While the market is still developing, factors such as increasing industrialization, foreign investments, and government initiatives to improve manufacturing competitiveness contribute to the growth of production monitoring in Latin America. The region also presents opportunities in sectors such as automotive, aerospace, and food and beverage, where there is a growing need for real-time monitoring and optimization of production processes.

Middle East & Africa

The Middle East & Africa region is witnessing steady growth in the adoption of production monitoring solutions. Countries such as Saudi Arabia, the United Arab Emirates, and South Africa are investing significantly in manufacturing sectors such as automotive, chemicals, and pharmaceuticals. The implementation of production monitoring systems helps enhance productivity, reduce costs, and ensure compliance with quality standards. Moreover, the region's rapid industrialization, infrastructure development, and government initiatives like Industry 4.0 adoption drive the demand for production monitoring solutions in the Middle East & Africa, making it a promising market to watch.

Company Profiles:

The primary stakeholders within the Global Production Monitoring sector are tasked with creating and executing production monitoring systems designed to assist businesses in monitoring and enhancing their manufacturing procedures. These systems offer immediate insight into production operations, enhance operational effectiveness, and maintain quality assurance standards.

Key participants in the Production Monitoring industry enlist Siemens AG, ABB Ltd, Rockwell Automation Inc, Emerson Electric Co, Schneider Electric SE, General Electric Co, Endress+Hauser Management AG, Yokogawa Electric Corporation, Honeywell International Inc, and Bosch Rexroth AG. These organizations specialize in delivering production monitoring solutions and services across various sectors like manufacturing, automotive, oil and gas, and pharmaceuticals. Their offerings encompass a variety of products and services aimed at supervising and managing production processes, monitoring equipment performance, enhancing production efficiency, and ensuring adherence to quality standards and regulations. These leading entities play a pivotal role in fostering innovation and technological progress in the production monitoring sector, supporting businesses in attaining operational excellence and ened productivity levels.

COVID-19 Impact and Market Status:

The global production monitoring market has experienced substantial disruption due to the Covid-19 pandemic, resulting in decreased demand and disruptions in supply chains.

The global production monitoring market has been significantly impacted by the COVID-19 pandemic, which has caused widespread disruptions across various industries. Lockdowns and travel restrictions have led to the closure or reduced operation of many manufacturing facilities, resulting in a decline in production activities. This has led to a reduced demand for production monitoring systems as companies focus on cost-saving initiatives. Moreover, disruptions in the supply chain have resulted in delays in the delivery of production monitoring equipment and software.

Nevertheless, the pandemic has underscored the importance of real-time monitoring and control of production processes. This has prompted an increased awareness and investment in digital technologies that support remote monitoring and automation. As industries adapt to the changing landscape and strive to enhance efficiency in their production processes, the production monitoring market is anticipated to gradually recover.

Latest Trends and Innovation:

- On January 15, 2021, Siemens AG announced its acquisition of TimeSeries, a leading provider of production monitoring and analytics software.

- On March 8, 2021, InfinityQS International, Inc., a provider of manufacturing analytics and quality software solutions, launched its latest version of ProFicient, an innovative production monitoring platform.

- On May 11, 2021, Sight Machine Inc., a real-time manufacturing analytics platform, announced its nership with Epicor Software Corporation to provide enhanced production monitoring capabilities to their joint customers.

- On July 22, 2021, Rockwell Automation, Inc., a global provider of industrial automation and digital transformation solutions, acquired Plex Systems, a leading provider of cloud-based manufacturing execution systems (MES) and production monitoring software.

- On September 29, 2021, Dassault Systèmes SE, a multinational software company, introduced DELMIA Apriso Production, a new offering aimed at providing advanced production monitoring and optimization capabilities to manufacturers.

- On November 18, 2021, Yokogawa Electric Corporation announced the release of its new production monitoring and visualization software suite, YoVisualization, empowering manufacturers with real-time insights into their operations.

- On December 9, 2021, Parsec Automation Corp, a provider of real-time manufacturing data solutions, expanded its product portfolio with the launch of TrakSYS™ 10, an upgraded version of its production monitoring and management software.

Significant Growth Factors:

Driving the expansion of the Production Monitoring Market are factors such as the rising need for enhanced operational productivity, increasing uptake of industrial automation, and progressions in real-time data analysis.

The global production monitoring industry is poised for substantial growth in the near future. A significant contributing factor to this growth is the rising prevalence of real-time monitoring and control systems within manufacturing sectors. These systems empower organizations to monitor and evaluate their production processes in real-time, facilitating the identification of bottlenecks, enhancement of efficiency, and minimization of downtime. Furthermore, the incorporation of cutting-edge technologies such as the Internet of Things (IoT) and artificial intelligence (AI) into production monitoring systems is a driving force behind market expansion. These advancements enable functionalities like predictive maintenance, automated data analysis, and proactive decision-making, thereby further elevating production effectiveness. In addition, the surging demand for economical and scalable solutions is propelling the adoption of cloud-based production monitoring platforms that provide enhanced flexibility, accessibility, and data security. The industry is also witnessing a ened emphasis on quality assurance and adherence to regulatory standards across diverse sectors, which is fueling the need for production monitoring solutions that guarantee product uniformity and compliance. Furthermore, the market is benefiting from the increasing trend towards digital transformation and the necessity for real-time data visibility and analytics. Overall, the anticipated significant growth of the production monitoring market in the forthcoming years is expected to be driven by the convergence of technological progress, cost-efficient solutions, and sector-specific requirements.

Restraining Factors:

The expansion of the production monitoring sector might face limitations due to the significant expenses associated with its implementation and a limited level of understanding within various industries.

The production monitoring sector encounters various obstacles that could impede its advancement and acceptance. Among the primary difficulties is the significant upfront investment needed to implement production monitoring systems. The expenses associated with hardware, software, installation, and customization can be substantial, icularly for small and medium-sized enterprises (SMEs) operating within constrained financial parameters. Another challenge is the intricate nature of integrating production monitoring systems with existing infrastructure and outdated equipment. This integration process can be prolonged and may necessitate specialized IT knowledge, presenting a hurdle for organizations lacking internal technical expertise. Moreover, employees unaccustomed to using production monitoring tools may exhibit resistance to change and require training to fully leverage the system's functionalities. Additionally, apprehensions regarding data security and privacy could impede the uptake of production monitoring solutions, as companies may have concerns about exposing sensitive manufacturing data to potential cyber threats. Lastly, the lack of awareness and comprehension regarding the advantages and potential return on investment of production monitoring systems may discourage adoption.

Key Segments of the Production Monitoring Market

Component Overview

• Solutions

• Services

Deployment Mode Overview

• On-premise

• Cloud

Application Overview

• Business Process Optimization

• Logistics and Supply Chain Management

• Emergency and Incident Management

• Automation and Control Management

Organization Size Overview

• Large Organization

• Small & Medium Organization

Industry Vertical Overview

• Oil & Gas

• Chemical

• Automotive

• Energy & Power

• Food & Beverage

• Aerospace & Defense

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America