Market Analysis and Insights:

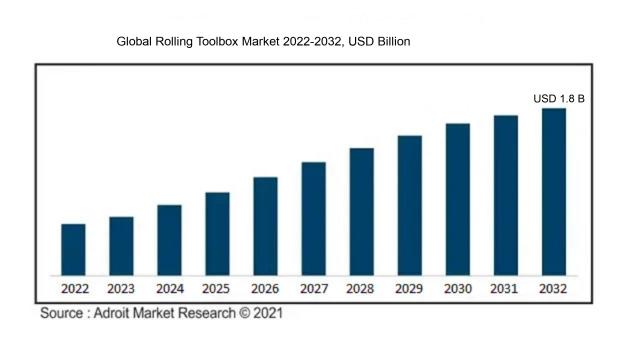

The market for Global Rolling Toolbox was estimated to be worth USD 1.2 billion in 2023, and from 2024 to 2032, it is anticipated to grow at a CAGR of 4.5%, with an expected value of USD 1.8 billion in 2032.

Key elements driving the rolling toolbox market include a ened need for effective organization and mobility in tool storage, especially among professionals in sectors like construction, automotive, and maintenance. The surge in DIY activities among homeowners and enthusiasts further stimulates this demand, as people seek robust and portable options for tool organization. Innovations in materials and design, including lightweight composites and ergonomic features, improve functionality and attract buyers. Moreover, the growth of e-commerce has expanded access to a wide array of choices, enhancing consumer selection. Increased environmental awareness is influencing buying behaviors, leading to a preference for sustainably produced goods. Effective pricing strategies and creative marketing approaches are crucial for engaging a varied consumer audience, thereby fostering growth in the rolling toolbox market. Collectively, these factors create a vibrant landscape that motivates both established companies and newcomers to innovate and meet the changing preferences of consumers.

Rolling Toolbox Market Scope :

| Metrics | Details |

| Base Year | 2024 |

| Historic Data | 2020-2023 |

| Forecast Period | 2024-2032 |

| Study Period | 2023-2032 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2032 | USD 1.8 billion |

| Growth Rate | CAGR of 4.5% during 2024-2032 |

| Segment Covered | By Type, By Application, Regions |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Stanley Black & Decker, Milwaukee Tool, Husky, Craftsman, Dewalt, Keter, Veto Pro Pack, 3M, Ridgid, and Seville Classics. Other important entities include Rubbermaid, Klein Tools, Apollo Tools, WEN Products, CRAFTSMAN, and Omega National Products. |

Market Definition

A mobile tool chest is a wheeled storage solution intended for the convenient transportation of tools and equipment. It generally includes several sections that allow for organized storage and quick access to various items needed for different jobs.

The Rolling Toolbox is essential across multiple sectors, significantly improving efficiency and organization for individuals in fieldwork or workshops. Its portable design enables easy movement of tools and equipment, lessening the time lost in locating items and alleviating physical exertion. With its structured storage solutions, it guarantees that tools are quickly reachable and safeguarded against harm. Furthermore, the Rolling Toolbox enhances safety by maintaining orderly work environments, thereby decreasing the likelihood of accidents. This versatile tool carrier is vital for mechanics, contractors, and DIY aficionados, streamlining workflows and enhancing the quality of project results.

Key Market Segmentation:

Insights On Key Type

Steel Rolling Toolbox

The Steel Rolling Toolbox is expected to dominate the Global Rolling Toolbox Market due to its unmatched durability and strength. Steel is preferred by professionals in various industries due to its capacity to withstand heavy tools and equipment without wearing out. The resilience of steel against environmental conditions also plays a critical role in its popularity, making it the go-to option for construction, automotive, and heavy-duty applications. Furthermore, the increased emphasis on safety and longevity in tool storage solutions has led to higher demand for steel options, surpassing others. As industries grow and expand, the need for robust tool storage that can endure rigorous use positions steel as the leading choice.

Aluminum Rolling Toolbox

The Aluminum Rolling Toolbox is recognized for its lightweight and corrosion-resistant properties, making it appealing for users who prioritize portability alongside strength. While it may not match steel in terms of regenerative toughness, aluminum boxes often cater to those in sectors such as plumbing and electrical work, where ease of transport is essential. The aesthetic appeal of aluminum, coupled with its ability to be anodized for added protection, also attracts those who want organized tool storage without a hefty weight. This option caters well to hobbyists and professionals alike looking for a balance between functionality and ease of use.

Plastic Rolling Toolbox

The Plastic Rolling Toolbox serves as an economical choice aimed primarily at casual users and hobbyists. With lightweight construction and affordability, this type appeals to a of the market that requires tool storage solutions for simpler tasks around the house or in less demanding professional settings. The resistance to rust and some chemicals is an advantage, although it lacks the durability of its metal counterparts. Moreover, plastic options frequently feature diverse storage configurations, providing users flexibility for organizing various tools. They are ideal for DIY projects but may not meet the rigorous demands of heavy-duty industries.

Insights On Key Application

Automobile Maintenance

The automobile maintenance sector is expected to dominate the global rolling toolbox market due to the increasing complexity of automotive systems and the growing need for effective and efficient repair solutions. As vehicles become more technologically advanced, mechanics and technicians require specialized tools that ensure precision and safety during repairs. Additionally, the rise in vehicle ownership and the frequency of routine maintenance and repairs further catalyze the demand for rolling toolboxes in this industry. The need for mobility within workshops and garages enhances the appeal of rolling toolboxes, making them indispensable in urban settings where space efficiency and accessibility are crucial.

Manufacturing Plant

In the manufacturing plant sector, rolling toolboxes play a significant role in facilitating production efficiency and organization. They provide easy access to tools and small parts, helping workers maintain productivity and reducing downtime. Despite not leading the market, the demand remains strong due to the increase in automation and the need for maintenance in various manufacturing processes. Factories prioritize mobile storage solutions that enhance workflow, and the growing emphasis on lean manufacturing practices supports further demand, albeit at a lower rate compared to the automobile maintenance sector.

Others

The Others category encompasses a range of applications where rolling toolboxes are utilized, including home DIY projects, construction, and education. While this does not dominate the market, it still shows potential for growth as consumer interest in DIY and home repair projects rises. The versatility of rolling toolboxes makes them appealing to hobbyists and professionals alike, leading to steady demand. However, this interest does not compare in scale to the commercial demands seen in the automobile maintenance industry, placing "Others" as a valuable yet less dominant player in the rolling toolbox market.

Insights on Regional Analysis:

Asia Pacific

The Asia Pacific region is set to dominate the Global Rolling Toolbox market due to several compelling factors such as rapid industrialization, growing manufacturing sectors, and increasing urbanization in countries like China and India. The region has witnessed a significant rise in construction activities and infrastructure development, consequently driving the demand for rolling toolboxes. Moreover, the growing awareness of ergonomic and efficient tool storage solutions among consumers and businesses is fueling market growth. The expanding automotive and electronics industries in the region also contribute to the increasing demand for organized tool management solutions, positioning Asia Pacific as the leading market for rolling toolboxes.

North America

North America, particularly the United States and Canada, plays a significant role in the global rolling toolbox market. The region boasts a strong manufacturing base and a high prevalence of DIY (Do It Yourself) culture, which drives demand for high-quality rolling toolboxes. In addition, innovations in product technology and strong brand loyalty among consumers ensure sustained growth. The presence of key players and advanced logistics systems aids in the efficient distribution of products, contributing to North America's solid market position.

Europe

Europe is home to several leading manufacturers and a well-established tool market. The demand for rolling toolboxes in the region is propelled by an increasing number of home improvement projects and a trend towards professional-grade tools among hobbyists and tradespeople. Europe also focuses on sustainability and eco-friendly products, which are influencing design and materials for rolling toolboxes. However, economic fluctuations can impact consumer spending, making market growth variable across different countries in this region.

Latin America

In Latin America, the rolling toolbox market is characterized by emerging consumer bases and a growing interest in professional tools among tradespeople. Countries like Brazil and Mexico see a rise in construction projects and infrastructure investments, thus increasing demand for effective tool storage solutions. However, economic challenges and political instability can hinder market growth and the expansion of manufacturing capabilities in the region, limiting its overall impact compared to more developed areas.

Middle East & Africa

The Middle East & Africa region presents a unique landscape for the rolling toolbox market, with significant growth driven by burgeoning construction and oil industries. Major projects in urban development, particularly in the Gulf states, spark demand for efficient tool management solutions. However, economic and developmental disparities among countries in this region can impede uniform market growth. Limited consumer awareness of tool organization solutions can also pose challenges but presents opportunities for market education and growth in the future.

Company Profiles:

Major contributors to the worldwide rolling toolbox market foster innovation and superior quality by creating robust, accessible products that appeal to both professional tradespeople and DIY enthusiasts. Furthermore, they pursue strategic collaborations and promotional campaigns to boost brand visibility and extend their market presence.

Prominent participants in the Rolling Toolbox industry consist of Stanley Black & Decker, Milwaukee Tool, Husky, Craftsman, Dewalt, Keter, Veto Pro Pack, 3M, Ridgid, and Seville Classics. Other important entities include Rubbermaid, Klein Tools, Apollo Tools, WEN Products, CRAFTSMAN, and Omega National Products. Furthermore, companies such as Southwire, Delta Industries, and GEARWRENCH are also influential within this market.

COVID-19 Impact and Market Status:

The Covid-19 pandemic brought substantial changes to the Global Rolling Toolbox market, driving a rapid transition to online sales and ening the demand for tools intended for home improvement, as numerous individuals took on DIY projects during the lockdown periods.

The COVID-19 crisis had a profound impact on the market for rolling toolboxes, primarily driven by changes in consumer preferences and industrial requirements. With the onset of global lockdowns, there was a notable increase in DIY initiatives as individuals spent more time at home, boosting the demand for rolling toolboxes intended for personal use. Concurrently, the pandemic caused significant supply chain disruptions, resulting in production and distribution delays that hindered the availability of these products. The construction and manufacturing industries experienced temporary halts, which diminished the need for professional-grade toolboxes in the early stages of the pandemic. Nevertheless, as economies started to reopen and infrastructure projects were kicked off again, the market began to recover. Moreover, with an increased focus on safety and organization within work environments, consumers began to seek out robust and effective storage options, further enhancing growth in the rolling toolbox sector. In conclusion, while the pandemic presented initial challenges, it ultimately catalyzed trends that contributed positively to the long-term prospects of the industry.

Latest Trends and Innovation:

- In January 2023, Milwaukee Tool announced the launch of new outdoor power equipment, including battery-powered hedge trimmers and leaf blowers that integrate advanced technology for improved performance and user-friendliness.

- In June 2022, Stanley Black & Decker completed its acquisition of MTD Products Inc., a manufacturer of outdoor power equipment, expanding its portfolio in the outdoor tools and enhancing its market reach.

- In March 2023, DeWalt introduced their FlexVolt system, which allows users to interchange batteries across various tools, improving efficiency and reducing downtime for professionals in the construction industry.

- In September 2022, Makita unveiled a new line of cordless power tools that utilize their latest brushless motor technology, enhancing runtime and durability while minimizing maintenance needs.

- In February 2023, Bosch Power Tools announced a partnership with the software company PlanGrid, aimed at integrating digital tools into their power tool offerings for improved project management and documentation on job sites.

- In April 2023, Ryobi launched a new series of smart tools that connect via Bluetooth to mobile devices, allowing users to monitor battery life and tool performance from their smartphones.

- In May 2022, Husqvarna expanded its robotic lawn mower offerings with the introduction of updated models featuring improved navigation technology and integrated weather sensors for optimal mowing efficiency.

- In August 2023, Snap-on Incorporated acquired the assets of a leading automotive tool company, thereby strengthening its position in the automotive repair sector and expanding its product line with innovative hand tools.

Significant Growth Factors:

The market for rolling toolboxes is expanding, fueled by a rising need for portable storage options, innovations in tool organization systems, and a growing consumer enthusiasm for do-it-yourself projects.

The market for rolling toolboxes is experiencing noteworthy expansion, driven by several influential elements. Primarily, there is a growing need for mobility and convenience in tool storage among professionals in construction, engineering, and DIY endeavors, leading to a preference for rolling designs that facilitate easy transport. In the wake of increased home renovation activities, particularly following the pandemic, consumers are demonstrating a rising interest in versatile and practical storage options. Additionally, innovations in materials and design have allowed manufacturers to produce toolboxes that are both durable and lightweight, significantly improving user experience.

The proliferation of e-commerce has also played a crucial role, enhancing access to a wider variety of toolboxes and enabling consumers to easily compare features and pricing. Moreover, there is a noticeable trend where hobbyists and DIY enthusiasts are gravitating towards professional-grade tools, broadening the market demographic as individuals seek effective organization and mobility for their extensive collections. Sustainability has emerged as an important factor, with a growing inclination towards eco-friendly materials reflecting the market’s evolution. Finally, the recovery and growth of the global construction and maintenance sectors continue to drive demand for high-quality rolling toolboxes, indicating a positive growth outlook for the industry in the coming years. Collectively, these factors render the rolling toolbox market a vibrant within the larger home improvement and construction landscape.

Restraining Factors:

The Rolling Toolbox Market encounters challenges including elevated production expenses and rising competition from other storage alternatives.

The Rolling Toolbox Market encounters a variety of challenges that could impede its expansion. A primary obstacle is the surging competition from alternative storage options, such as modular storage units and premium tool cabinets, which not only provide comparable functionality but also offer superior design and durability. Additionally, volatility in the prices of raw materials, especially metals and plastics utilized in the production of toolboxes, can result in rising costs for manufacturers, which may impact pricing strategies and profit margins.

Furthermore, the increasing inclination towards digital solutions in workshops and tool management may diminish the demand for conventional rolling toolboxes, as professionals increasingly turn to smart organizational systems. Supply chain disruptions, intensified by global issues such as pandemics or geopolitical conflicts, represent another significant challenge, complicating manufacturing processes and causing delays in product distribution.

Moreover, limited awareness among consumers regarding the benefits of high-quality rolling toolboxes could restrict market growth. However, with the rising DIY movement and a growing emphasis on organization and efficiency among consumers, the Rolling Toolbox Market is expected to evolve and innovate, thereby opening new avenues for growth and ensuring a favorable outlook for the future.

Key Segments of the Rolling Toolbox Market

By Type

• Steel Rolling Toolbox

• Aluminum Rolling Toolbox

• Plastic Rolling Toolbox

By Application

• Automobile Maintenance

• Manufacturing Plant

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America