Specialty Polymer Market Analysis and Insights:

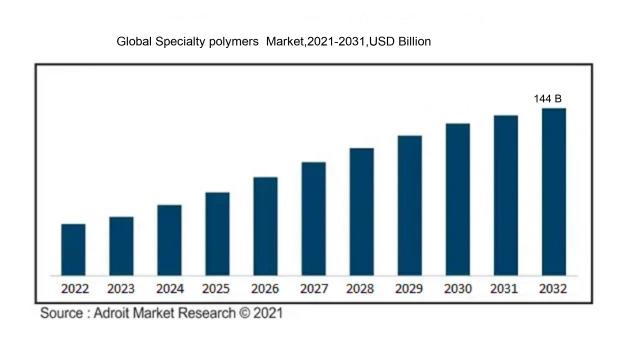

In 2023, the size of the Global Specialty Polymer market was US$ 81.6 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 6.27 % from 2024 to 2032, reaching US$ 144 billion.

The pecialty polymers market is influenced by several critical elements, notably the rising demand in diverse sectors such as automotive, electronics, and healthcare. This increased interest can be attributed to the unique characteristics of these materials, such as their durability, flexibility, and resistance to heat and chemicals. In the automotive arena, the trend towards lightweight materials aimed at improving fuel efficiency is driving up the utilization of specialty polymers.

Additionally, technological advancements are paving the way for the creation of high-performance polymers, which broaden their applications in electronic devices and medical equipment. There is also a growing focus on sustainability, prompting manufacturers to explore biodegradable and environmentally friendly polymer alternatives. Furthermore, the proliferation of emerging markets offers fresh prospects for the specialty polymer sector, as local industries seek innovative solutions tailored to their specific needs. Together, these dynamics forge a strong growth trajectory for the specialty polymer market, positioning it advantageously within the global material framework.

Specialty Polymer Market Definition

Specialty polymers are specifically formulated polymers created to serve particular purposes that demand distinctive characteristics, such as improved durability, resistance to heat, or protection against chemicals. These materials are frequently customized to fulfill the requirements of specialized sectors in industries including automotive, aerospace, and electronics.

Specialty polymers play a vital role in various industries due to their distinctive properties and customized functionalities that meet particular demands. These advanced materials exhibit superior resistance to chemicals, extreme temperatures, and mechanical stress, rendering them suitable for applications in sectors such as aerospace, automotive, electronics, and healthcare. Their adaptability fosters innovative designs and solutions, propelling technological advancements while enhancing product durability and reliability. In addition, specialty polymers promote energy efficiency and sustainability by facilitating the creation of lighter, more resilient components, ultimately leading to decreased resource consumption and a reduced environmental footprint. As industries progress, the increasing need for specialty polymers highlights their importance in contemporary manufacturing processes.

Specialty Polymer Market Segmental Analysis:

Insights on Product Type

Specialty Elastomers

Specialty Elastomers are expected to dominate the Global Specialty Polymer Market characterized by their exceptional elasticity and flexibility, making them valuable in applications such as automotive seals, gaskets, and medical devices. Their growing usage in industries that prioritize energy efficiency and eco-friendliness is boosting their market presence. Manufacturers are increasingly looking to replace traditional rubber materials with specialty elastomers that offer better performance and durability. The innovation in product formulations designed for specific end-use applications is expected to maintain their relevance and gradual growth in the market.

Specialty Thermoplastics

Specialty Thermoplastics are growing due to their versatility and wide application across various industries such as automotive, electronics, and consumer goods. Their properties, which include high durability, lightweight construction, and excellent thermal resistance, have made them increasingly popular in the manufacturing processes of a range of products. The growing demand for innovative and sustainable materials, particularly in high-performance applications, is propelling the adoption of specialty thermoplastics. Additionally, technological advancements and increased investments in research and development are further fostering market growth in this area, making it the leading type in the specialty polymer sector.

Specialty Composites

Specialty Composites play a vital role in providing enhanced mechanical properties and lightweight solutions. Their applications span the aerospace, construction, and wind energy sectors, where strength-to-weight ratios are crucial. The increasing focus on sustainable materials and the rise of green technologies are encouraging the integration of specialty composites in various engineering processes. Continued advancements in composite manufacturing techniques, alongside the push for improved performance in demanding environments, are likely to drive their steady growth in the specialty polymer market.

Specialty Thermosets

Specialty Thermosets are known for their exceptional thermal stability and chemical resistance, which makes them suitable for high-temperature applications. They are widely used in the automotive and aerospace industries for components that require long-term performance under stress. However, their growth may be limited compared to specialty thermoplastics, as the latter offers more flexibility in processing and application versatility. Nevertheless, ongoing research into enhancing the properties of thermosets may yield further opportunities for market penetration, especially in niche applications.

Others

The "Others" category encompasses additional product types that cater to specialized applications within the polymer market. This includes unique or emerging materials that do not fit neatly into the other classifications. While the contributions of this category may currently be smaller in scale, innovations and developments in biopolymers or other emerging technologies can potentially position them as significant candidates for market expansion. However, the overall impact is expected to remain limited compared to the major players of specialty thermoplastics and elastomers in the foreseeable future.

Insights on End User

Automotive and Transportation

The automotive and transportation sector is witnessing significant growth and is expected to dominate the Global Specialty Polymer Market. The transition to electric vehicles (EVs) and the incorporation of advanced technologies require durable and high-performing materials for various components. As environmental regulations become stricter, the demand for innovative solutions, such as polymers that can withstand high temperatures and resist degradation, continues to rise. Thus, this sector is experiencing substantial growth in the adoption of specialty polymers, contributing positively to market dynamics.

Healthcare

The healthcare industry is growing due to the increasing demand for medical devices, drug delivery systems, and biocompatible materials. The growth in healthcare spending and technological advancements in medical applications have driven the need for specialty polymers that offer enhanced performance and safety. Additionally, the ongoing innovations in medical technology emphasize the importance of high-quality materials that can meet stringent regulatory standards, thereby increasing their application in this sector. This trend indicates a significant future trajectory for specialty polymers in healthcare-related applications, ensuring their dominance in the market.

Consumer Goods

In the consumer goods industry, specialty polymers are gaining traction due to evolving consumer preferences for sustainable and high-performance products. The shift towards eco-friendly materials is driving manufacturers to explore polymers that offer recycling potential while maintaining durability and quality. Various applications, from packaging to household goods, benefit from specialty polymers that provide enhanced aesthetics and functionality. Consequently, this sector is becoming a notable participant in the specialty polymer market, particularly as brands focus on innovation to meet consumer needs.

Building and Construction

Specialty polymers play a crucial role in the building and construction industry, especially in applications such as sealants, adhesives, and coatings. The growing emphasis on energy efficiency and sustainable building practices is fueling the demand for high-performance materials that can provide insulation and durability. Innovations in polymer technology offer solutions that improve the lifespan and resistance of materials used in construction, ensuring safety and effectiveness. This sector’s focus on sustainability and resilience highlights the increasing use of specialty polymers in various construction applications.

Coatings, Adhesives, and Sealants

The coatings, adhesives, and sealants showcases significant application of specialty polymers due to their versatility and specialized properties. Innovations in polymer chemistry offer enhanced adhesion, weather resistance, and durability, making them ideal for a multitude of surfaces and environments. As industries strive for better protection and aesthetic appeal, the demand for advanced coatings and adhesives rises, positioning specialty polymers as indispensable. This growth is further fueled by the increasing need for products that comply with environmental regulations, underscoring the importance of these materials in applications across different sectors.

Electrical and Electronics

The electrical and electronics market utilizes specialty polymers for components that require high reliability and performance. As the industry embraces miniaturization and advanced technologies, the need for insulating and thermally stable materials has significantly increased. Specialty polymers enable manufacturers to create efficient and safe devices while addressing challenges related to heat, moisture, and electrical conductivity. This emphasis on innovation ensures that specialty polymers will continue to find robust applications within the ever-evolving landscape of electrical and electronics, making it a dynamic area of growth.

Global Specialty Polymer Market Regional Insights:

Asia Pacific

Asia Pacific is expected to dominate the Global Specialty Polymer market due to its rapidly expanding manufacturing sector, increasing industrialization, and growing demand for innovative materials across various applications. The region benefits from a robust supply chain and technological advancements, particularly in countries like China, India, and Japan. High investments in automotive, electronics, and construction industries are driving the adoption of specialty polymers. Moreover, the large consumer base and a shift towards sustainable solutions are fostering market growth. The region's ability to leverage low-cost production while enhancing quality further solidifies its position as the leading market for specialty polymers.

North America

North America holds a significant share of the specialty polymer market, primarily due to its advanced technology and high consumer spending in industries such as automotive and healthcare. The presence of major manufacturers and a focus on R&D initiatives are factors contributing to its market presence. However, the growth rate is likely to be slower compared to Asia Pacific, as companies increasingly look to Asia for cost-effective manufacturing capabilities.

Europe

Europe is also a vital market for specialty polymers, particularly driven by stringent regulations on polymer usage and a strong focus on sustainability and recycling. The automotive and aerospace sectors are leading consumers of specialty polymers in this region. Even though Europe has established companies and innovative startups, its market growth may be challenged due to economic uncertainties and reliance on imported materials.

Latin America

Latin America is gradually emerging in the specialty polymer market as regional economies stabilize and investments in infrastructure improve. Brazil and Mexico are the players in this market, focusing on sectors like packaging and consumer goods. However, its market is still smaller compared to other regions, facing challenges such as fluctuating economic conditions and limited manufacturing capabilities that hinder rapid growth.

Middle East & Africa

The Middle East & Africa region is currently a minor player in the specialty polymer market, mainly influenced by the oil and gas industry. Although efforts are being made to diversify economies and invest in manufacturing, challenges such as political instability and lack of infrastructure slow growth. However, with increased investment from various industries, there is potential for future market development in specialty polymers.

Specialty Polymer Market Competitive Landscape:

Prominent figures in the worldwide specialty polymer sector are at the forefront of innovation and product advancement, emphasizing cutting-edge applications in diverse industries. They actively pursue strategic collaborations and investments aimed at expanding market presence and promoting sustainability efforts.

Prominent entities within the specialty polymer sector encompass BASF SE, DuPont de Nemours, Inc., Evonik Industries AG, Solvay S.A., The Dow Chemical Company, Mitsubishi Chemical Corporation, Huntsman Corporation, Covestro AG, LyondellBasell Industries Holdings B.V., Arkema S.A., SABIC, Kraton Corporation, Eastman Chemical Company, 3M Company, and Celanese Corporation.

Global Specialty Polymer COVID-19 Impact and Market Status:

The Covid-19 pandemic had a profound impact on the Global Specialty Polymer market, resulting in interruptions in supply chains and a decline in demand across multiple sectors, especially in automotive and aerospace, which in turn caused a temporary deceleration in growth.

The COVID-19 pandemic has profoundly impacted the specialty polymer industry, introducing both hurdles and prospects. Initially, production was impeded by supply chain disruptions and the temporary shutdown of manufacturing plants, resulting in diminished demand in sectors like automotive and aerospace. Conversely, this crisis also ened the need for specialty polymers in healthcare settings, including applications in medical devices, personal protective equipment, and pharmaceutical packaging. The rising standards for biocompatibility and safety in these areas spurred innovation and increased investment in polymer technologies. Additionally, the ened awareness of sustainability and environmental issues during the pandemic has led manufacturers to investigate bio-based and recyclable polymer options, altering the landscape of the market. As economies begin to recover and industries evolve, the specialty polymer sector is expected to rebound, supported by continuous technological progress and a shift in consumer preferences towards more robust and sustainable materials. In essence, the pandemic has served as a driving force for transformation within the specialty polymer arena.

Latest Trends and Innovation in the Global Specialty Polymer Market:

- In March 2023, BASF announced its acquisition of Solvays’ global polyamide business, enhancing BASF’s position in the specialty polymers market and expanding its offerings in high-performance materials.

- In June 2023, Covestro introduced a new line of polycarbonate materials designed specifically for electronics applications, improving sustainability by utilizing recycled content and innovative manufacturing processes.

- In September 2022, Evonik Industries launched a new product line of high-performance specialty polymers aimed at automotive applications, which will enhance vehicle lightweighting and energy efficiency.

- In January 2023, Huntsman Corporation completed its acquisition of Gabriel Performance Products, strengthening its position in the specialty additives sector and expanding its specialty polymer portfolio.

- In February 2023, DuPont announced a significant investment in its specialty polymers manufacturing facility in Virginia, focusing on expanding production capabilities for its high-performance polymers used in the electrical and electronic industries.

- In April 2023, SABIC and ExxonMobil announced a strategic collaboration to develop advanced polymer materials that could serve the 5G telecommunications market, focusing on enhancing signal quality and durability.

- In December 2022, 3M launched its updated portfolio of fluoropolymer products aimed at improving performance in high-temperature applications, reflecting ongoing innovation in specialty polymers for industrial uses.

Specialty Polymer Market Growth Factors:

The Specialty Polymer Market is poised for growth driven by several factors, including ened demand from various sectors, innovations in polymer technologies, and an increasing emphasis on environmentally sustainable materials.

The Specialty Polymer Market is witnessing robust expansion influenced by several pivotal elements. Primarily, the rising necessity for lightweight materials within the automotive and aerospace sectors is driving the use of specialty polymers, renowned for their superior strength-to-weight ratios. Additionally, the increasing requirement for innovative materials in electronic devices—especially in the development of flexible and high-performance technologies—is spurring advancements in polymer formulations. Environmental regulations emphasizing sustainable materials are further invigorating market growth, compelling manufacturers to explore bio-based and recyclable specialty polymers.

Furthermore, the healthcare sector's expansion, where specialty polymers play a crucial role in medical devices and drug delivery systems, is enhancing the market's outlook. The uptick in construction activities, particularly related to infrastructure projects, is also raising the demand for specialty coatings and adhesives. Advances in polymer processing techniques and formulation methodologies are facilitating the development of tailored solutions, thereby broadening market access. Moreover, the ongoing trends towards automation and digitalization across multiple industries are anticipated to generate fresh opportunities for specialty polymers, thus expanding their range of applications. In summary, these interconnected factors are driving the Specialty Polymer Market towards continued growth as sectors strive for innovative materials aligned with their evolving needs.

Specialty Polymer Market Restaining Factors:

The Specialty Polymer Market faces challenges due to elevated manufacturing expenses and rigorous regulatory standards that hinder innovation and impede new entrants into the market.

The Specialty Polymer Market is confronted with various obstacles that could impede its expansion. A primary concern is the elevated costs associated with raw materials, which may restrain production capabilities and elevate the prices of end products. Furthermore, stringent environmental regulations and the demand for sustainable alternatives present significant hurdles for manufacturers, as compliance often entails substantial investments in research and development efforts.

The market is also characterized by fierce competition, resulting in price battles between both established companies and newer entrants, which further compresses profit margins. In addition, variable demand from major end-use sectors such as automotive, electronics, and healthcare brings uncertainty to production planning. Disruptions in the supply chain, intensified by geopolitical conflicts and global events like health crises, can adversely affect material availability and lead to delays in the manufacturing process.

Lastly, the swift pace of technological innovation necessitates ongoing development, which can be resource-intensive for businesses. Nevertheless, in spite of these challenges, the Specialty Polymer Market is set for growth, propelled by expanding applications in cutting-edge technology domains and an increasing need for eco-friendly materials, highlighting a robust and adaptable future for the industry.

Specialty Polymer Market Segments:

By Product Type

- Specialty Elastomers

- Specialty Composites

- Specialty Thermoplastics

- Specialty Thermosets

- Others

By End User

- Automotive and Transportation

- Consumer Goods

- Building and Construction

- Coatings, Adhesives, and Sealants

- Electrical and Electronics

- Healthcare

- Others

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America