Strain Gauges Market Analysis and Insights:

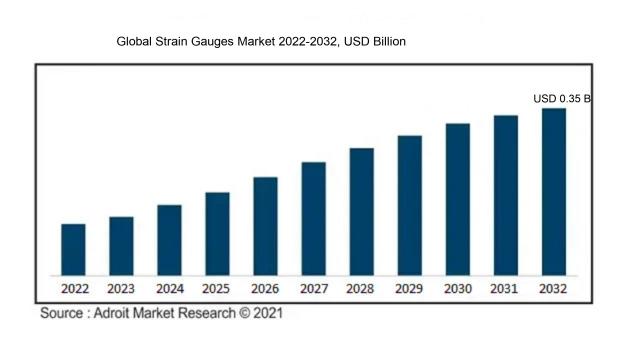

The market for Strain Gauges was estimated to be worth USD 0.2 billion in 2023, and from 2023 to 2032, it is anticipated to grow at a CAGR of 4.5%, with an expected value of USD 0.35 billion in 2032.

The Strain Gauges Market is propelled by a multitude of interrelated factors, notably the escalating need for systems that monitor structural integrity, technological advancements, and an increasing emphasis on automation within various industries. The demand for accurate measurement of mechanical strain across diverse fields such as aerospace, automotive, and civil engineering is a significant driver of market growth. Moreover, ened research and development initiatives are focused on creating innovative and highly sensitive materials for strain gauges, thereby broadening their use in medical applications and smart manufacturing solutions. Additional motivations for the rising implementation of strain gauges include environmental considerations and the enforcement of safety regulations aimed at ensuring the integrity of infrastructure. The prevailing trend of real-time data collection, coupled with the incorporation of Internet of Things (IoT) technologies into measurement frameworks, further augments the capabilities and relevance of strain gauges, ultimately facilitating market growth as industries strive for enhanced operational efficiency and elevated safety standards.

Strain Gauges Market Definition

Strain gauges are highly accurate instruments designed to assess the level of deformation or strain that an object undergoes when subjected to stress. Their functionality is based on the principle that the electrical resistance of a conductor varies in response to deformation, allowing for the measurement of structural alterations.

Strain gauges play a vital role in engineering and materials evaluation, as they provide precise measurements of deformation or strain in objects under stress. This measurement ability is crucial for evaluating structural strength, maintaining safety in construction and industrial processes, and refining product design. By delivering real-time information, strain gauges enable engineers to track performance and foresee possible failures across numerous fields, including aerospace and civil engineering. Their significance is amplified in research and development, where analyzing material responses to varying loads can inspire technological advancements and improve product longevity, thereby fostering increased safety and efficiency.

Strain Gauges Market Segmentation:

Insights On Key Type

Electrical Strain Gauge Sensors

Electrical Strain Gauge Sensors are expected to dominate the Global Strain Gauges Market due to their widespread application across various industries, particularly in civil engineering, aerospace, and automotive sectors. The efficacy of these sensors in measuring strain with precision ensures their preference in critical applications where accuracy is paramount. Moreover, advancements in technology have led to the development of more sensitive and durable electrical sensors, further increasing their appeal. The ability to integrate these sensors with digital technology and data acquisition systems enhances their usability and expands their scope, solidifying their leading position in the market over Mechanical Strain Gauge Sensors and others.

Mechanical Strain Gauge Sensors

Mechanical Strain Gauge Sensors offer unique advantages, particularly in applications where high robustness and reliability are crucial. These types of sensors are often favored in settings that involve extreme environmental conditions such as high temperatures and pressures, making them ideal for certain industrial applications. While they may not be as widely used as Electrical Strain Gauge Sensors, they still hold a significant market share thanks to their simplicity and cost-effectiveness. Their ability to operate without the need for an external power source adds to their appeal in specific scenarios, ensuring they remain relevant despite the advancing technology in electrical sensors.

Others

The Others category includes various alternative measurement technologies, such as optical and fiber optic strain gauges, which have specific applicability in niche markets. These options tend to be utilized in specialized fields, including advanced research, medical instrumentation, and high-performance aerospace applications, where conventional strain gauges may not suffice. While their market share is relatively smaller compared to Mechanical and Electrical Strain Gauge Sensors, the continuous innovation in alternative technologies is contributing to a gradual increase in their adoption. Emerging applications and increased focus on specialized environments are expected to drive growth within this category, albeit at a slower rate.

Insights On Key Mounting Type

Bounded Strain Gauges

The Global Strain Gauges Market is expected to be dominated by bounded strain gauges. This category is widely favored for its superior bonding capabilities and reliability in various industrial applications. Bounded strain gauges provide a robust connection to the substrate they are attached to, ensuring precision and durability. As industries increasingly demand accuracy and reliability, bounded strain gauges stand out for their ability to deliver consistent performance in measurement and monitoring environments. This is particularly prevalent in sectors like aerospace, automotive, and civil engineering, where the integrity of measurements is crucial. The expected growth in these sectors further reinforces the predominant position of bounded strain gauges in the market.

Unbounded Strain Gauges

Unbounded strain gauges offer certain advantages, particularly in applications where minimal intrusion on the substrate is essential. They can be applied quickly and easily, which makes them suitable for temporary or less critical measurement tasks. Often used in experimental setups or in situations where flexibility is needed, unbounded strain gauges allow for easy repositioning and adjustment. However, their sensitivities and lower adhesive properties compared to bounded gauges limit their use in high-stakes applications.

Insights On Key Sensor Type

Semiconductor Strain Gauges

Semiconductor strain gauges are expected to dominate the Global Strain Gauges Market due to their high sensitivity and precision. They outperform traditional foil gauges in applications requiring minute measurements, making them ideal for diverse sectors like aerospace, automotive, and medical devices. Their ability to function efficiently in extreme conditions enhances their appeal among manufacturers seeking reliable solutions for stress analysis and performance monitoring. Furthermore, advancements in semiconductor technology have led to increased reliability and miniaturization options, allowing for their integration into compact electronic systems. The growing demand for automation and sophisticated monitoring systems further solidifies the leading position of semiconductor strain gauges.

Optical Sensors

Optical sensors are gaining traction in the strain gauge market due to their ability to provide non-contact measurement, resulting in reduced wear and tear on the sensors themselves. These sensors utilize techniques such as fiber optics to detect strain, which makes them an appealing option for applications in environments where electromagnetic interference could be an issue. Their usage is prevalent in industries like civil engineering, where monitoring structural integrity in real-time is critical. However, the higher cost associated with optical sensors could limit their widespread adoption in certain budget-sensitive applications.

Photoelectric Gauges

Photoelectric gauges are popular for their straightforward operational mechanism in detecting strain or displacement changes. They excel in applications requiring fast response times and high accuracy, commonly found in manufacturing and automation systems. With the growing trend of smart factories and Industry 4.0 implementations, the demand for photoelectric gauges is expected to see notable growth. Yet, while they offer distinct advantages, their reliance on proper alignment and potential sensitivity to environmental conditions may hinder their performance in some specialized scenarios.

Thin-Film Strain Gauges

Thin-film strain gauges find favor in applications requiring miniaturization, as they can be manufactured in very small sizes without losing performance. Their thin profile allows for integration into complex electronic circuits, making them suitable for use in medical devices, automotive sensors, and consumer electronics. Nonetheless, the sensitivity levels and operational stability in high-temperature conditions can sometimes be a limitation, especially in demanding environments. While they offer several benefits, the more established methods may overshadow them in highly critical applications requiring extreme reliability.

Diffused Semiconductor Strain Gauges

Diffused semiconductor strain gauges are characterized by their ability to measure higher strains compared to their counterparts, which makes them suitable for applications in harsh environments. They are often utilized in industrial machinery and structural health monitoring owing to their durability and effectiveness under stress. Nevertheless, their integration might not be seamless in all setups due to the specific installation requirements and costs involved. Consequently, while they offer valuable features for niche applications, their overall market share may remain limited relative to other sensor types that offer broader versatility.

Insights On Key Application

Strain Measurement

The Strain Measurement category is expected to dominate the Global Strain Gauges Market due to its critical role in various industrial applications. Strain gauges are extensively used to measure deformation in materials subjected to stress, making them indispensable in sectors such as construction, aerospace, and automotive. The increasing need for structural health monitoring and safety in infrastructure projects, coupled with rising investments in advanced manufacturing processes, significantly boosts the demand for strain measurement devices. Furthermore, the growing trend toward precision engineering and the introduction of new technologies enhancing gauge performance are contributing to its dominance in the market.

Vibration Monitoring

Vibration Monitoring is another significant application area within the Global Strain Gauges Market. It is crucial for maintaining the operational efficiency and reliability of machinery and equipment. Industries such as energy, manufacturing, and transportation utilize vibration sensors to monitor the condition of rotating machinery, detect faults early, and prevent costly downtimes. The increasing emphasis on predictive maintenance and the growing use of IIoT technologies further enhance the demand for vibration monitoring applications in various sectors, positioning it as a vital area within the strain gauges market.

Residual Stress

Residual Stress is a notable application area in the Global Strain Gauges Market, particularly in the realm of material performance evaluation. It plays a pivotal role in ensuring the longevity and durability of components by detecting internal stresses that can lead to failure. Industries like aerospace, automotive, and construction utilize residual stress measurements to optimize designs and enhance safety. With the ongoing advancements in materials science and engineering techniques, the relevance of residual stress assessment is likely to grow, though it remains secondary to the dominant strain measurement application.

Torque Measurement

Torque Measurement represents an important within the Global Strain Gauges Market, particularly in applications where accurate torque data is vital to operational performance. It is extensively used in automotive testing, machinery calibration, and quality assurance processes. As manufacturers emphasize efficiency and precision in mechanical systems, torque measurement continues to gain traction. However, it remains a lesser priority when compared to the broader and more widespread application of strain measurement.

Deflection & Bending Measurement

Deflection & Bending Measurement is a valuable application area, particularly in structural engineering and design verification. It helps in evaluating the performance of beams, bridges, and other structural elements under load. Ensuring safety and compliance with engineering standards drives the demand in this area. Though essential, it typically garners less attention than strain measurement, as the latter is more widely applicable to various mechanical assessment scenarios across multiple industries.

Insights on Regional Analysis for Strain Gauges Market:

Asia Pacific

Asia Pacific is expected to dominate the Global Strain Gauges market due to rapid industrialization, significant investments in manufacturing, and a growing focus on infrastructure development. Countries like China, Japan, and India are experiencing a surge in manufacturing activities, leading to an increased demand for strain gauges in various applications, including automotive, aerospace, and construction. The region's ability to produce low-cost yet high-quality strain gauges also contributes to its competitive edge. Furthermore, advancements in technology and the presence of major players in this market bolster the Asia Pacific's position, as the region continues to innovate and meet the growing requirements of various sectors.

North America

North America holds a significant position in the Global Strain Gauges market, primarily due to its advanced technological infrastructure and robust industrial applications. The region houses numerous key players and innovators that drive demand, especially in sectors like aerospace and automotive, where precision measuring is critical. Moreover, investments in research and development enable the introduction of sophisticated strain gauge technologies, helping industries to improve their operational efficiency and product longevity.

Europe

Europe is a substantial market for strain gauges, largely fueled by its sophisticated manufacturing base and strong regulatory frameworks requiring high-quality measurement standards. The automotive and aerospace industries are particularly prominent here, driving demand for precise measurement instruments. Additionally, Europe's commitment to enhancing technological capabilities and its focus on research and innovation provide a supportive environment for strain gauge applications, although it often faces stiff competition from the Asia Pacific region.

Latin America

Latin America is witnessing moderate growth in the strain gauges market, driven by increasing investments in infrastructure and construction projects across various countries. The demand for strain gauges is gradually rising due to the enhancement of manufacturing processes and the need for better quality control measures. However, challenges like economic instability and limited technological advancement compared to other regions impede more rapid growth.

Middle East & Africa

In the Middle East & Africa, the strain gauges market is emerging, supported by infrastructural developments and a growing focus on industrial automation. Regions like the Gulf Cooperation Council (GCC) are investing heavily in construction and oil industries, which require efficient monitoring systems. However, the market still faces hurdles due to a lack of comprehensive manufacturing facilities and reliance on imports for technological needs, restricting its overall growth potential.

Strain Gauges Market Company Profiles:

Prominent entities in the global strain gauges market, encompassing both producers and vendors, propel innovation and the evolution of products while upholding quality standards to cater to a variety of industrial needs. Their collaborative alliances and technological progress boost market competitiveness and broaden their international presence.

The strain gauge market is characterized by several prominent companies, including Vishay Precision Group, Inc., Hitec Products AS, Omega Engineering, Inc., Tokyo Measuring Instruments Laboratory Co., Ltd., and Kaman Corporation, Micro-Measurements, a division of Vishay Precision, and suppliers such as TML (Tokyo Measuring Instruments Laboratory Co., Ltd.) and Heraeus Group play significant roles. The sector also features semiconductor giants like Honeywell International Inc. and Tektronix, Inc. Moreover, other noteworthy players consist of Flintec, Futek Advanced Sensor Technology, Inc., PCB Piezotronics, Geosense, and specialized manufacturers like FUTEK Advanced Sensor Technology and Zemic.

COVID-19 Impact and Market Status for Strain Gauges Market:

The Covid-19 pandemic profoundly impacted the Global Strain Gauges market, causing interruptions in manufacturing operations and supply chains, which resulted in variable demand and postponements in product availability.

The COVID-19 pandemic had a profound effect on the strain gauge market, presenting both hurdles and new possibilities. At the onset, disruptions in manufacturing and a reduced demand from essential industries like automotive, aerospace, and manufacturing adversely impacted sales figures. The implementation of lockdowns and interruptions in supply chains decreased production capabilities and pushed back project schedules. Nonetheless, as industries adjusted to new operational conditions, the demand for strain gauges rebounded, particularly in sectors such as healthcare and infrastructure, where monitoring structural integrity became essential. The ened emphasis on automation and remote monitoring further fueled market expansion. With a gradual recovery of the global economy, advancements in strain gauge technology, including wireless sensing solutions, are anticipated to propel future developments. Overall, the outlook for the strain gauge market in the post-pandemic era appears positive, bolstered by a renewed commitment to safety and efficiency across multiple industries, signaling a transformative period for the sector.

Strain Gauges Market Latest Trends and Innovation:

- In July 2021, Hitec Products, a leader in the design and manufacturing of strain gauges, announced the acquisition of DSI (Digital Sensor Innovations), enhancing their product portfolio in industrial applications and structural health monitoring solutions.

- In March 2022, Vishay Precision Group introduced a new line of low-profile strain gauges aimed at improving measurement accuracy in applications such as robotics and automotive components, showcasing advanced technology that reduces noise and enhances temperature stability.

- In November 2022, Omega Engineering launched a new strain gauge series with an ultra-thin profile and high sensitivity, which is designed for applications requiring precise measurements in constrained spaces, further expanding their existing offerings in the strain gauge market.

- In January 2023, Kistler Group completed the acquisition of Piezotronics, Inc., significantly enhancing their capabilities in sensor technology, including strain gauges, with a focus on expanding their reach within the automotive and aerospace sectors.

- In June 2023, Micro-Epsilon released an innovative capacitive elongation sensor that utilizes strain gauge technology, aimed at providing precise displacement measurement for automation and robotics applications, demonstrating the integration of traditional technologies with modern engineering needs.

- In August 2023, the National Instruments Corporation announced the launch of their latest data acquisition system that incorporates advanced strain gauge measurement technology, designed to improve data precision in scientific research and industrial testing.

- In September 2023, Vishay Intertechnology unveiled new high-temperature strain gauge sensors capable of withstanding extreme conditions, catering to the oil and gas industry, which requires robust and reliable measuring devices for demanding environments.

Strain Gauges Market Significant Growth Factors:

The growth of the strain gauge market is propelled by technological innovations, a ened requirement for accurate measurement across diverse sectors, and a surge in the utilization of sensor-oriented solutions in automated systems.

The Strain Gauges Market is set to experience substantial growth due to several critical drivers. Firstly, the ened need for accurate measurement across a range of sectors such as automotive, aerospace, and manufacturing demands dependable strain measurement technologies. Additionally, the emergence of smart materials and the proliferation of the Internet of Things (IoT) amplify the necessity for sophisticated sensing solutions, which incorporate strain gauges into intelligent devices for continuous monitoring and data acquisition. Technological advancements, particularly in the realm of high-performance, flexible, and wireless strain gauges, support a wide array of applications, facilitating market development.

Moreover, an increased focus on structural health assessment within civil engineering to ensure safety and manage risks has spurred the demand for these sensors. Investment in research and development aimed at creating innovative strain gauge designs plays a crucial role in driving market progress. Furthermore, the rising implementation of automation and robotics across various industries leads to greater reliance on strain gauges for both dynamic and static load analysis. Together, these elements foster a strong environment for the strain gauges market, positioning it for ongoing expansion as industries increasingly emphasize precision and operational efficiency in their processes.

Strain Gauges Market Restraining Factors:

The strain gauges market encounters significant hurdles, such as their ened sensitivity to environmental factors and the necessity for meticulous calibration, both of which can hinder their broader acceptance and utilization.

The strain gauge industry encounters multiple factors that could impede its expansion. A significant obstacle is the elevated cost linked to advanced strain gauge technologies, which may restrict their uptake, particularly by small and medium-sized enterprises. Furthermore, the susceptibility of strain gauges to environmental variables—such as changes in temperature and humidity—can compromise their precision and consistency, potentially deterring some users. The intricate nature of installation and calibration processes may also represent a challenge for sectors that lack specialized expertise or trained personnel. Additionally, the rising presence of alternative measurement technologies, like fiber optic sensors, introduces competitive pressures for conventional strain gauges. Stringent regulatory requirements across various fields, especially in aerospace and automotive industries, may complicate the approval pathways for new innovations. Nonetheless, the market holds potential for growth driven by the increasing need for accurate measurement across a range of industries, including construction and electronics, where technological progress continues to improve functionality. Innovations in strain gauge materials and the integration of smart technologies could enhance usability and expand their applications, ensuring a dynamic future for the industry as it adapts to new demands.

Key Segments of the Strain Gauges Market

By Type:

• Mechanical Strain Gauge Sensors

• Electrical Strain Gauge Sensors

• Others

By Mounting Type:

• Bounded Strain Gauges

• Unbounded Strain Gauges

By Sensor Type:

• Optical Sensors

• Semiconductor Strain Gauges

• Photoelectric Gauges

• Thin-Film Strain Gauges

• Diffused Semiconductor Strain Gauges

By Application:

• Vibration Monitoring

• Residual Stress

• Torque Measurement

• Strain Measurement

• Deflection & Bending Measurement

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America