Advance Search

Selective Catalytic Reduction: Important For Controlling NOx Emissions

By Grishma Khairnar | Mar 2019

Nitrogen oxide emissions are contributing to the global environmental problems, including photochemical smog, acid rain and elevated fine particulate levels. To understand this better this white paper highlights information regarding the legislative and regulatory factors responsible for controlling the emission of NOx. This paper will also provide the details regarding Selective Catalytic Reduction i.e. SCR and its role in controlling the emission of NOx along with its future prospects. This report also focuses on temperature application range for different catalysts. The future developments mentioned is useful for increasing the market of selective catalytic reduction in the future.

Nitrogen oxide emissions are contributing to the global environmental problems, including photochemical smog, acid rain and elevated fine particulate levels. To understand this better this white paper highlights information regarding the legislative and regulatory factors responsible for controlling the emission of NOx. This paper will also provide the details regarding Selective Catalytic Reduction i.e. SCR and its role in controlling the emission of NOx along with its future prospects. This report also focuses on temperature application range for different catalysts. The future developments mentioned is useful for increasing the market of selective catalytic reduction in the future.

Emissions of nitrogen oxide (NOx) is substantially contributing in the national environmental problems, involving elevated fine particulate levels, photochemical smog (ozone) and acid rain. Ozone exposure is connected to various health effects, comprising the notable decrease in the functioning of lungs, airway inflammation and a rise in the symptoms of respiration. The guidelines developed in the response to the issues of ozone urged the selective catalytic reduction (SCR) application on the wide range of industrial sources of emissions of NOx. In U.S., SCR is being applied on the industrial boilers and utility, process heaters, gas turbines, chemical plants, steel mills and internal combustion engines. Strict guidelines and experience in operating are resulting in the increase in the systems of SCR installed in U.S. Increase in the experience of owners in operating and producers are concentrating on lessening the operations costs and enhancing the performance of SCR.

Legislative and Regulatory factors for the technologies of NOx control:

The latest regulations established in response to ozone standards are the initial driver for the NOx control technologies installation on sources like coal-fired power plants. As an industry sector, coal-fired power plants are close to one-third of NOx emissions in U.S. Responding to the emissions from power plants, the first regulatory drivers was the Acid Rain Program established from Title IV of the changes to 1990 Clean Air Act (CAA). The initial method of agreement for Acid Rain Program was with the help of application of Low NOx burner (LNB) technology and emissions leading in multiple boilers in the company’s fleet of boilers.

Most recent regulatory drivers for NOx control at coal-fired power plants was U.S. Environmental Protection Agency’s (EPA) Clean Air Interstate Rule (CAIR). Various lawsuits were registered against CAIR important to the U.S. Court of Appeal’s December 2008 decision to imprison the rule back EPA for revisions.

Necessity for controlling NOx Emissions:

Nitric oxide is identified as a colorless gas that transforms in the atmosphere to NO2 as yellow-brown plume. NOx is harming the environment and human health directly and takes part in the photochemical smog, acid rain, atmospheric fine particles, visibility impairment and nitrogen deposition. Following are the factors of NOx that harm environment and human health:

· Nitrogen dioxide is responsible in causing the severe human health like pneumonia, bronchitis, lung irritation and viral infection.

· NOx emissions are leading towards the creation of ground level ozone. Ozone harms the functioning of lung and exaggerates the heart disease and respiratory diseases like bronchitis and asthma.

· NOx emissions contribute to nitrogen deposition and acid rain that destroys fish and other forms of coastal and freshwater life and destroy the materials and buildings, agricultural crops and forests. In the western areas of United States, NOx emissions are the main cause of acid deposition. NOx are contributing in the nitrification of rain that may “over fertilize” the soil, parting foliage to damage from insects, cold and disease.

What is Selective Catalytic Reduction (SCR)?

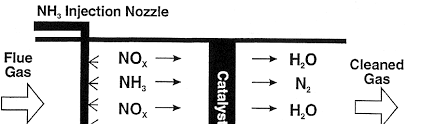

In the procedure of SCR, a catalyst simplifies a chemical reaction between ammonia and NOx to generate nitrogen and water. Ammonia steam or ammonia air mixture is inserted in the exhaust gases comprising NOx. SCR is the procedure for controlling the nitrogen oxides emission from the stationary sources. The main principle of SCR is the lessening of NOx to nitrogen (N2) and water (H2O) by reacting with NOx and ammonia in the catalyst bed.

catalysts are accessible for the use for different applications and operating conditions. The longest base metal catalysts contain vanadium and titanium oxides and even contain tungsten, molybdenum and other elements. Base metal catalysts are applied to the applications of mid-temperature range. For low-temperature range applications, catalysts containing metals like palladium and platinum are applied. For high temperature, zeolite catalysts are used. At various sites in U.S., high-temperature (zeolite) catalyst are installed upstream of HRSG or at turbine exhaust in the applications of simple-cycle, where temperature may be greater than9501050°F.

Some Means for Improving Catalyst Performance:

Many of the SCRs are designed for the removal of more than 90% of NOx and less ammonium slip. Competition to keep SCR as inexpensive and small has pushed the SCR margins to very tight levels having little room for error. Three areas are very essential for maintaining the performance of SCR:

- Distribution of Ammonia:

Unequal distribution of ammonia across the catalyst reactor is the main cause of poor SCR performance and may be misguided for the low catalyst activity. If ammonia is not distributed properly with the help of exhaust gas, some parts will be excessively treated, brings about high ammonia slip and the different parts might be undertreated that results in low NOx reduction. The main reason for high ammonia slip on the systems of SCR may be due to the high removal rates of NOx as there is little chance for error in the ammonia distribution. The highest ammonia slip can reach the levels that are convinced for causing problems, like localized deposits of ammonium bisulfate in the air preheater or high ammonia in fly ash.

- Maintaining the Catalyst:

For maintaining the proper working of catalyst is the part of large catalyst management program that involves the priorities like periodic catalyst testing and sampling and exchange/ replacement evaluations based on the efficiency of NOx reduction, evaluation of catalyst physical condition, regular ammonia slip monitoring and more.

Many of the units are fortified with the SCR systems have witnessed the severe catalyst plugging problems as the result of formation of large particle ash in boiler and low-density. This kind of ash is not cleaned with the methods of cleaning as it lodges in the channel of catalyst. Hence, when this kind of plugging occurs, it is very important to take SCR for offline cleaning. Ash screens situated near the outlet of economizer hopper has proved to be very helpful.

- Managing the Catalyst:

Catalyst management mainly includes the monitoring of the activity of catalyst, planning for the additions of future activity and make the decision for regenerating or replacing the catalyst as required. Catalyst will not be able to find the overtime activity because of the material deposits that blocks the active sites, by poisoning of the chemical of active components and by physical damage and erosion.

Application Temperature Range for Types of SCR Catalyst:

Operating temperature is the main input of design for SCR catalyst. It orders the suitable formulation of catalyst and materials of module construction for the application to meet the requirements of NOx reduction, pressure loss, ammonia slip and oxidation of SO2 on the given catalyst operation period. Applications of low temperature are limited by the capability for the formation of ammonium nitrates or ammonium sulfates. Applications of high temperature are limited SO2 oxidation, ammonia oxidation and catalyst operating life.

Recent Innovations in SCR:

Manufacturers of catalyst have sustained to enhance catalysts and increase the capabilities of SCR catalyst. Current designs of SCR catalyst are more resilient to poisoning and erosion than earlier designs and have operating lives. Catalysts for the high-temperature operating, for instance, simple cycle turbines are searching for the increased use. Catalysts are reducing the emissions of furan and dioxin and the NOx emissions being installed on the units of incinerators. Additionally, SCR catalyst formulations are advanced to surge the oxidation of mercury for enhanced capture in the emissions of control equipment.

Future Prospects:

The application of SCR to simple cycle combustion turbines has augmented. This is because of the advanced utilization and installation of turbines for meeting the demand of peak power. Moving ahead, the range signifies an area where there is no huge experience with SCR, especially greater than 800°F. Experience in this range is limited because of the absence of the SCR requirements in past and low operating hours that are accumulated naturally on the application of a simple cycle.